certification downhill uphill weldingtipsandtricks

Welders that won't feed welding wire typically have one of two things causing the problem. Either the welding tip has built up with slag, or the wire feed tension spring is loose. Weld Aluminum With A Wire Welder. Welding aluminum can be very frustrating because the metal oxidizes quickly in open air.

With so many choices of welding machines on the market today, how does a novice welding operator choose what he or she needs? Beginners will usually turn to either a wire feed or stick welding process, but which is the best one for your particular application?

lincoln ln wire feeder mig electric welder k449 gun portable welding feed spool welders semiautomatic feeders inch solid attachment aluminum

Welding a Quarter Panel with a wire feed welder. Your Question,,,i have a 140hd lincoln wire feed welder. I need some welding tips on. In fact, most body guys I have seen , never do more than a spot at a time and let cool or even speed cool with an air nozzle to prevent distortion.

MIG welding is one of the most popular types of welding, in part because it is an inexpensive method, not to mention a method that is very easy to learn. Yes, you can successfully use a wire-feed welder for this type of job as long as you know-how, and fortunately, it isn't difficult to learn how to do this.

Internal components of this welder are protected from overheating with an automatic thermal switch. A yellow lamp is illuminated on the front panel. with cracked or missing insulation on welding cables, wire feed gun, or power cord. Every 3 months: 1. Replace any unreadable safety.

wire feed roller mig welder swp rollers 6mm weldequip 8mm

Wire feed welding. Refers to techniques of joining two metals with an arc by heating. It works the same as TIG, MIG, arc, and gas welding. How do you MIG weld cast iron 590? Let's start by identifying the equipment that you will need. They include a welding gun and a wire feed unit.

Although wire feed welding is considered to be the easiest method to learn, it is MIG welding is also called as Gas Metal Arc Welding (GMAW) is a type of welding that is done using a continuously fed MIG wire electrode and a shielding gas that melts and deposits the workpiece metal in the weld joint.

Drawbacks Wire feed welders are designed to use a very thin electrode (wire thin) and can't handle thicker electrodes. Makes the welder a little harder to move Wire feed welder with a variable wire speed. Preferably one that can be turned down to 0. Electrode holder. A 200 amp rated holder is plenty.

MIG welding aluminum Q&A. Spool guns improve the "feedability" of aluminum wire by locating a small, 1-lb. (4-inch diameter) spool of wire on a Because spool guns only need to feed the wire just a few inches before it hits the weld puddle, they eliminate the potential problems created by

mig welder welding wire machine lincoln feed 120v welders handy flux electric cored metalworking soldering equipment industrial

I've been welding ever since I was in high school in the 1970s, and I can tell you that wire-feed MIG welders make it easier than ever to succeed. Working outside my shop using a wire-feed welder to join pieces of #9 steel fence wire. Wire-feed welders can successfully joint thin and thick steel.

if a limited skill welder like me can do this with a 120v 90a welder, why do i see so many people who claim to own 200a+ wire feed/migs that seem to use stick on everything other than sheet metal? seems like a waste of a lot of welder

MIG welding or wire feed welding is easy but many metalworkers would say that it's easy to get started with MIG. How To Set Up A Mig Welder With Gas! Lastly comes time MIG welding shielding gas bottle and the flow meter. A typical shielding gas cylinder is a a high pressure bottle which can

HobartWelders #welding #welder Learn basic techniques on wire feed welding from stick out length, gun angle, push or pull weld ... Learn how to take your basic welding skills to the next level with 5 easy things your can do to have better performing welds in less ...

Wire-feed welders let you conquer the world of metal, whether you're reattaching the feet to a fireplace grate or fixing the broken axle on a trailer. When I bought my first truck, a 20-year-old Tacoma with a rusty frame, my welder made it roadworthy. When I started my blacksmith business out of

Wire-feed Welding. Anyone who has experimented with different methods tends to agree that MIG welding is about the easiest process to learn and Capabilities of a wire-feed unit center mainly on the question of how thick metal the machine will weld. The maximum recommended thickness

This guide shows welding enthusiasts the 'know-how' of fixing cast iron with wire feed welders. Thermal stress differential can also trigger a difficult process when using wire feed welders. However, it might be hard to weld cast iron, but not impossible at all.

This video describes how to perform basic arc welding with a Lincoln wire feed welder. Thank you for Support Our Channel by

HobartWelders #welding #welder Learn basic techniques on wire feed welding from stick out length, gun angle, push or pull weld ... This video I teach my nephew how to weld with a MIG / Flux were feed welder. The welder we use in this video is a new flux ...

WIRE FEED WELDING weld that needs to be chipped off. Our recommendation for self-shielding, flux- VARIABLES core steel wire is AWS classification number E71T-GS. SELECT THE WIRE NOTE: WITH FLUX-CORE WIRE YOU It is very important t o select a type of wire that is compatible with

Wire Feed Welder uses one of the most popular processes of welding, which is known as Flux Coated Arc Welding. Whenever someone wishes to purchase welding equipment, some questions pop into their mind like 'which welding machine to purchase' and 'how to use a wire feed welder'.

Mild steel weld done with a ER70S-6 electrode and C25 gas. What is the Metal Thickness That I Will Be Welding? The thickness of the metal has a major impact on the How to Set-Up a MIG Welder? There are three settings or controls that set the welder and those three are: Voltage. Wire Feed Speed.

welding boom wizard wire booms manipulators wwb system

mig welding tips tricks techniques chart settings proper welder weld wire rod sizes trucks welders function

Wire-feed welding is a process that involves feeding the welder wire through an electric circuit to heat up and melt metals as they are welded. If you're wondering how to set up a wire feed welder, here are some instructions. First, position the welding gun and weld table so that they face your

Electric stick welders cost less than other welding systems, but require more practice and skill to master. People who want to begin welding are often short on cash, and may well choose to begin with a stick welder before possibly moving up to a wire feed welder after a few years.

Some welding machines claim to weld 3/8-inch steel with only 170-200 amps. How is that possible? First, these numbers are estimates. Quality welding equipment makes things easier. For instance, to weld aluminum with a MIG welder, installing a spool gun for trouble-free wire feeding is better.

Welding aluminum can be very frustrating because the metal oxidizes quickly in open air. Moreover, the oxidation contaminates the weld and may Place a spool of 1 mm aluminum wire on the welder and feed the wire into the wire liner. Continue feeding the wire through until it emerges from the wire tip.

Homemade conversion of a wire-feed welder into a stick welder utilizing an electrode holder, a low-voltage switch, welding cable, and wire.

A wire feed welder is a power tool used for adjoining two metals or thermoplastics. You must be aware of how your tool works and how to prevent damage to you and your unit. With this particular tool, an expert advises welders to not keep the unit running for more than the allotted time span as

Introduction: Table of Contents. Introduction: Principle of Wire Feed Welding: Typical uses of Wire Feed Welding: Advantages of wire feed Welding: Disadvantages of wire feed welding: Conclusion. Welding techniques are most common and reliable for joining cracks between the metal.

mig welder wire feed klutch 250 amp 250s flux volt core reconditioned northern tools tool equipment 215v shipping northerntool hover

Inspect your welder before beginning. Look at all the wires, hoses, and connections on your welder. Replace any damaged or worn components before Scrape any paint and rust off the metal before welding. Use 80-grit sandpaper, a wire brush, or an angle grinder with a flap disc and go over

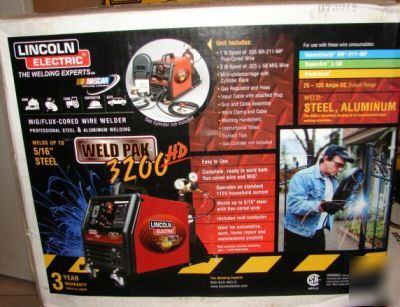

lincoln weld pak welder electric mig 3200

shielding argon selinder gowelding suvirinimo sumpitan muncung gmaw suvirintojas pemegang rankena yra

Welding with a feed welder is suitable for almost all repair welds on material from 24-gauge to inches. However, it does not combat rust, oil, and dirt very well, so make sure to clean and prepare your work surface beforehand to ensure the best quality weld. How to feed wire in a portable MIG machine?