Stick Welding Super Thin Sheet Metal Welding Thin Metal. In this episode my grandson broke the handle off a piece of garden ... Have you ever welded something so thin and worn out that all you do is blow holes in it? Did you want to learn how to work ...

argon

Welding techniques for thin metal. To avoid burn through of the thin metal you will need to be very careful not to whip or weave the torch. When welding move in a straight line and use the push technique of the MIG gun. To prevent blowout move the wire to cooler edges of the base metal.

Trickier is the "butt" weld, where two metals touch along the edges - it is difficult to keep the electrode traveling in a straight line along the joint, and tough I don't know how the weld manages to deal with the natural thin layer of oxide that rapidly forms on aluminum, but I believe/assume it just blasts away.

I love TIG welding, for welding thin metals it works the best… it is gentleman's welding, I seldom set myself on fire TIG welding. I can do very small Simply joking, this tip is to disclose how to weld sheet metal with a stick welder. A wire feed or tig welder is ideal for sheet metal in any case, we

welding tig stainless 6mm

If you weld a thin piece of metal with a higher than recommended amperage, the electric arc can burn through, rather than fuse, the base metals. The manufacturer's settings for amperage settings should only be adjusted in small increments to avoid burn-throughs. Failure to Prep.

Welding dissimilar metals is being done more often; therefore, this article is devoted to providing information for successfully joining some of The nickel or nickel deposit can be welded to the copper alloy using a nickel filler metal. Such a joint will provide satisfactory properties and will be successful.

saldatura tig metalli saldare minifaber robotizzata lamiere saldature lamiera lastre sottili

Use filler metals (wires) that are thinner than thin sheet metal. Most welders use wires with diameters of and inches for thin-sheet metalwork. How To Use TIG Welders For Thin Metal Sheets. Unlike the MIG welding process, the TIG welding technique offers clean and strong welds.

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding

How. Details: Welding thin metal to thick metal is a challenge all welders face at some point. At first, it seems easy, but once you learn the technique, they are not difficult to make. Whether you weld with a stick welder or a wire feed uni t, the technique and ideas are the same. mig welding thin metal.

welding sheet metal mig clamps butt panel patch weld automotive restore tack piece called place

Table of Contents Which polarity is the best to weld thin metal? How to prepare thin metal for stick welding? Stick welding thin metal is hard because this process produces a strong arc that inputs a lot

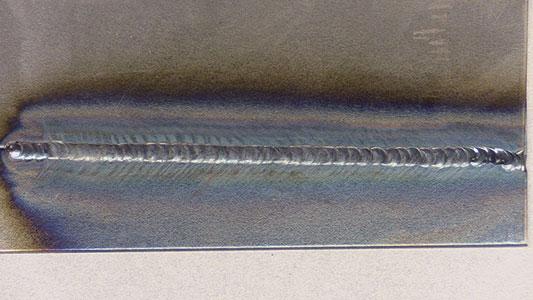

welding tig looks matter

Welding sheet metal is a completely different ballgame. When you're trying to fuse two pieces of 22 gauge (.030) things can easily ... I keep blowing through my thin sheet! Andy gives helpful insights and tips to MIG weld thin sheet metal.

corner welding outside weld tig mig types joint steel metal butt stainless gas purge tutorial section

This type of welding can also cause a lot of headaches and is actually one of the hardest welds to perfect, I for sure haven't perfected it yet! This is one of the most common uses for a MIG welder, butt welding thin bodywork-type sheet metal, normally for a classic car restoration or repair.

beam electron welding metals join process bodycote ebw metal joining heat electrons why processing thermal velocity treatment uses

Learn how to weld sheet metal QUICKLY with these EASY TO FOLLOW STEPS that will make your life a lot Butt welds are used for thin sheets of metal to make sure that the welding process can happen in a single pass. Things like the width of the weld, the thinness of the metals, what type

Welding thin steel. The butt weld page showed how to do a seam weld using a continuous torch movement. Try applying that technique to steel less than 1mm in thickness and you are likely to blow a hole in the metal.

Welding thin metal doesn't have to cause a headache! We've put together this relatively easy step-by-step guide to help you get started on your next Benefits of Using a MIG Welder to Weld Thin Metal. If you have the expertise, it's easy to operate the MIG welding gun. The trigger of the welding gun

I agree with practice makes perfect but to weld on thin guage metals without burning through requires the correct heat settings and wire speed. One guy said to get a thin metal plate and tack weld it in place or rivet it in place, even. You would probably want to pre-drill the hole for the cable to

Ready to learn how to TIG weld brass? Brass is the name of a pretty common metal that describes a wide range of copper alloys that contain additions This allows you to weld thinner metals or metals with high heat conductivity like brass without burning through them. To get started, try pulsing at

You can weld on metal with mill scale or rust. Disadvantages of Stick Welding. It requires more skill than MIG as you need to keep the electrode a certain distance from the metal as it burns down. It produces a lot more spatter and slag. Increased cleanup time results in decreased efficiency.

It is important to note that welding thin metal sections is very different from welding bridge girders or thick plates. 1) In the last 35 years, MIG welding has revolutionized how we join autobody metal. It is fast and efficient, and it provides good quality joints.

How thin of a piece of sheet metal can you (or have you) welded with a stick welder? I'm considering a Lincoln AC/DC stick welder and am concerned that a lot of welding/fix-it chores around the home is stuff that is as thin as 1/16" thick. Soooo, how thin to you go with your stick welder, what is

Welding thin metal is an art. Extreme heat or mis use of your welder can cause weak welding joints and beads. In this guide we review how to weld If you wish to understand how to weld slim metal without compromising it, then continue reading the guide to know more. Making the Burnout Lose.

When it comes to welding thin sheet metal like car body panels, if you are not experienced and skilled enough, then you can easily create a mess as blow In this article, we are taking a look at how people should go about welding sheet metal, what kind of wire and shielding gas need to be used along

tig welding connections wig fronius seams

Stick Welding Super Thin Sheet Metal Welding Thin Metal. In this episode my grandson broke the handle off a piece of garden ... videos related to welding how ti weld wide gap electrode: stainless sheet weld test ...

metal stud sheet steel welding stainless studs welded plate weld plates plant vandf gauge

How does one weld sheet metal? This is a question that many novice welders are concerned about when they start dealing with materials of different thicknesses. Sheet metal is a lot thinner than other materials that one needs to weld, so a completely different approach is needed.

The week we are going over how to weld thin metal like exhaust systems and turbo manifolds. The concept is actually fairly simple and you could be

Working with thinner sheets of metal is tricky. If you use too much heat, you may end up with a burn through. Too little may result in not enough weld penetration If you want to know how to weld thin metal, then keep on reading. To ensure a successful joint when working with thin gauge material,

Stick Welding Super Thin Sheet Metal Welding Thin Metal. In this episode my grandson broke the handle off a piece of garden ... This video shows you how to stick weld on thin metal with 7018 electrodes. These are 3/32 size rods that I'm using and the plates ...

The real trick to weld sheet metal is to use a wire feed. A wire feed or tig welder is ideal for sheet metal but, we will assume that you don't have one. We need to establish what is considered thin metal.

Stick Welding Super Thin Sheet Metal Welding Thin Metal. In this episode my grandson broke the handle off a piece of garden ... In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal.

The type of weld you need to make depends on how you plan on joining the pieces of metal. Each joint can be welded in a number of different styles to Secure the metal to a welding bench with fixtures and jigs. Place the stainless steel on a metal work surface. Arrange the steel pieces together.