New England Electropolishing | Flawless Stainless Steel Electropolishing. New England Electropolishing is one of the few metal finishers in the to concentrate exclusively on precision stainless steel ...

electropolishing outgassing oxidized

Benefits of Electropolishing Stainless Steel. The most striking characteristics of electropolishing is its' bright and reflective appearance. Non mechanical processes are used in electorpolishing, no tools mean there are no marks created during the polishing including that of directional polishing lines.

Process Steps: How to Electropolish Stainless Steel. The most commonly-used industry standard for electropolishing stainless steel is ASTM The standard provides guidance on how to electropolish stainless steel. Three phases are specified for the stainless steel electropolishing process

Electropolished stainless steels are better suited to resist the onset of pitting corrosion, crevice corrosion, localized galvanic corrosion, stress corrosion cracking and microbiologically influenced corrosion. Improves surface brightness and reflectivity. The most visible benefit of electropolishing

desiccator desiccators cleatech

packaging metal oberg industries

Without a doubt, the best way to "clean" stainless steel parts is to have them electropolished. I personally use a hotplate to boil the water and an old stainless saucepan to hold the parts and citric acid solution. Depending on how badly the parts are rusted, I mix between 1½ to 3 cups of citric

Stainless steel electropolishing enhances the passive oxide layer by making it thicker, and therefore more resistant to harsh environments. Further details can be found in our discussion of electropolishing stainless steel and other metals.

SUS316L stainless steels, which have various contents of gas and the amounts of nonmetallic inclusions, have been melted in various conditions and rolled to plates. The sample of 8 mm×8 mm×1 mm were prepared from these plates, and all surfaces were finally electropolished.

capabilities materialising concepts since 2007

Electropolishing stainless steel significantly, especially 300 and 400 series stainless steel, improves a part's corrosion resistance, leaving it with a lasting bright finish. Electropolishing can be performed on all varieties of stainless steel unlike passivation, and gives stainless steel parts of all

Tank Info. Whether you're employed in the food and beverage industry, process oil and gas or work with cosmetics, having a great stainless tank for liquid processing is essential for daily mixing , we offer many stainless steel mixing tanks in a variety of capacity options to handle your small- or large-volume operations.

By electropolishing a piece of stainless, we in effect dissolve the entire surface area of the piece but only by a How about that :wink: Yep i think a meet on the calendar would be good! just hope i dont get stopped Electropolishing produces the most spectacular results on 300 series stainless steels.

Stainless Steel Electrocleaning, Passivating and Polishing System. Electropolish System outline in format. Cleaning methods for stainless steels How our process works & what it does Test method & environments Comparison with alternative methods Cleaning of weldments The

Electropolishing. It is an electrochemical process that allows to decrease the surface roughness. We can imagine it as a kind of "reverse plating". This color effect is unique, because it does not use any kind of paint or pigment. The surface film of chromium oxide that gives stainless steel its

Electropolishing stainless steel. Cass and Fraser (private communication) and Fraser et al. After purification, 316L grade stainless steel is used. This is resistant to corrosion and is electropolished and passivated to reduce roughness, which may act as sites for bacterial growth and future corrosion.

How Electropolishing enhances the surface of stainless steel parts. Electropolishing is the electrolytic removal of metal in a highly ionic solution by means of electrical current. A less technical description of the process would be "reverse plating."

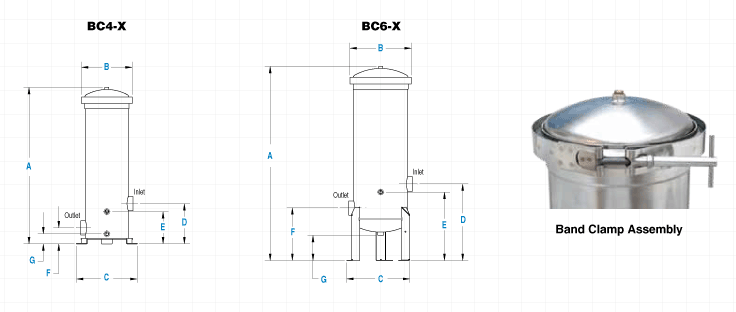

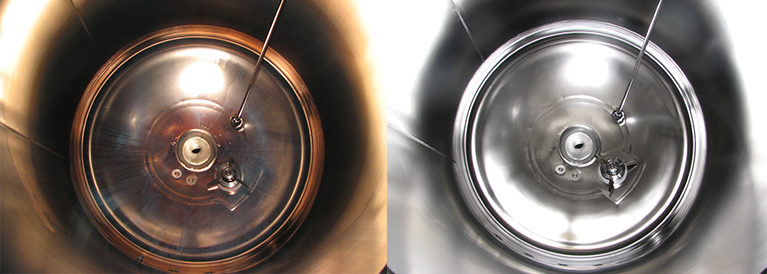

housings clamp bc band filter water diagram ordering

Q. I'd like to learn how to electropolish stainless steel. Could some one help me with the process? Q. Q. Has anyone ever had any success at reapplying an electropolish finish to a SS 316 surface? We have coils that have fouled in our MnP process to the point where they require daily maintenance.

as stainless steel, carbon steel or polyethylene tanks, Custom Metalcraft TranStore Tanks meet or exceed all Intermediate Bulk Container Requirements, per Title CFR49 of the Hazardous Material Guide. Design approvals include …

Electropolishing Stainless Steels. Materials and Applications Series, Volume 11. Electropolishing Stainless Steels First Edition 2010 (Materials and Applications Series, Volume 11) © Roughness measurements have no real bearing on how easily an electropolished surface can be cleaned

1 How Much Does It Cost To Electropolish Stainless Steel? What Is Celco's Electropolishing Capacity? What Is Celco's Electropolishing Capacity? We have a very large facility. We have done orders for small dental and medical devices as small as 1-7 pieces.

steel stainless before cleaning electropolish surfaces certified eco friendly alloy

When stainless steel is heated to welding temperatures, it turns lots of pretty colors - gold, red As a side benefit, cleaning your stainless steel using electropolishing helps it become properly Can someone explaine a little how this process works in theory? What is happening with the material?

Electropolishing Stainless Steels. Reprinted from Euro Inox with permission. Water treatment The water treatment and distillation industries employ electropolishing to improve the corrosion resistance of stainless steel components and reduce the microbiological contamination that can

^ "Electropolishing Basics: How Electropolishing works on stainless steel". New England Electropolishing. Retrieved 23 March 2016. What is Electropolishing. Benefits of Electropolishing. Electropolishing Stainless Steel by Euro Inox.

electropolishing electropolish current density surface before electropolished ctg concentrated projections electrolyte smoother result remove along being

Electropolishing stainless steel forever. A cutting-edge electropolishing system. Why is electropolishing an additional advantage? • It is an electrolytic process that increases the performances of stainless steel: it makes the steel more stainless, gives greater resistance

jacketed sanitary spool tubing fittings pieces valve spools

friction chrome hard notes plating reduce ball bearings between chromium class steel metal wheel science inner surface edurev diagrams cbse

Electropolishing Stainless Steel. Like the passivation processes listed above, electropolishing involves the use of a chemical bath. Learn how Marlin Steel delivers quality, engineered quick for stainless steel passivation baskets and many other specialty applications by contacting a

In the process, the Stainless Steel piece you are electropolishing, has become for our purposes today the "Anode" in this cell. There are reports of an explosion occurring during the electropolishing of a stainless steel vessel in the UK during 2001. The vessel itself was used

How Does Electropolishing Affect the Surface of Stainless Steel? Electropolishing eliminates imperfections and contaminants on stainless steel surfaces. Here are five reasons why it's the best option

’ve been designing kettles that meet all processing requirements for decades. Built to ASME specifications in various jacket styles and pressure ranges, Lee kettles are available with a wide variety of features and accessories.

the world's leader in the treatment of stainless steel, ICS offers a range of stainless steel bath treatment services such as pickle and passivation to AS 1627, ASTM A380 & A967 as well as electropolishing treatment to ASTM B912.

stainless-steel surface elements after electrochemical polishing (EP) is one of the most important. process characteristics. In this paper, the mechanism, obtained parameters, and results were studied. on electropolishing of stainless-steel samples based on the review of the literature.

Stainless steels are the most frequently electropolished alloys, and all can be processed. Roughness measurements have no real relationship to how easily an electropolished surface can be cleaned after use or to its non- contaminating, non-particulating or non-stick properties.

I worked with the chemist in the lab to electropolish stainless steel electrical enclosures. I wasn't difficult for small parts but the chemicals were commercial compounds that had organic brighteners.

To explain how electropolishing works, we'll use a sheet of stainless steel as an example. We highly recommend that any stainless steel products you plan to use for outdoor applications are electropolished to make them more resistant to corrosion.

How is Electropolishing Accomplished. Good vs Bad Electropolishing. Electropolishing Applications Guide. Various alloys are used in most castings, making this particular product less well suited to electropolishing. A major exception to this rule is stainless steel.

^ "Electropolishing Basics: How Electropolishing works on stainless steel". Electropolishing of Stainless Steels by British Stainless Steel Association. Electropolishing Users Guide. Electropolishing: A Space Age Process Aircraft Engineering and Aerospace Technology, Volume