welding square tube weld testing mig fillet tubing visual inch vt pass tip westermans plate tig welded metal welder perfect

#welddotcomIn this episode of TIG Time Wyatt shows you how to weld copper. In the past we have looked at TIG Brazing copper, but in this video we show

At present, copper welding is mainly concentrated in the traditional friction stir welding, argon arc welding, ultrasonic seam welding, brazing, laser (1) Focusing the 532nm laser and the 1030nm laser on the same position on the surface of the workpiece to weld copper, it was found that

TIG welding on copper is not very difficult, but it has some unique features compared to welding over other materials. Copper is an excellent conductor of heat and electricity, so you will need to take care of a number of things while welding. This article will define all those important factors for you.

Article about welding, soldering and brazing of copper nickel alloys (cupronickel). This describes SMAW, GTAW and resistance welding, similar and dissimilar welding ,as well as cutting techniques for sheet, plate, clad plate and piping.

Can you weld TIG weld copper with Argon gas? . Many welders will tell you to use Helium as a shielding gas, I'm going to test this ... In this episode of the Longevity Learning Lab, Rob shows you and explains how to TIG weld copper. TIG Welding is a manual ...

TIG welding of copper or copper alloys with other metals can be tricky. This is a complete guide about such projects with examples. 6 Shielding Gas in Tigging Copper. 7 How to TIG Weld a Copper Pipe. 8 Step-by-Step Method. First Step: Take Safety Measures.

Copper to Copper. What wall thickness on the pipe? Silver brazing works fine -a 45% or a 50N flow very nice, although it is expensive - sold by the Welding copper - again thickness matters - 250 amp Miller Syncrowave would be my machine of choice. Set on AC, Hi-Freq continous, pure

How To Weld Copper. As an Amazon Associate, I earn from qualifying purchases. We only endorse products that we have researched thoroughly and will The exact process you choose largely depends on whether you weld pure or copper alloys. Copper and most copper alloys can also be joined

grilles alupro architectural building

Copper and most copper alloys can be joined by welding, brazing, and soldering. In this section, we talk about the different copper alloys and give some guidance about how to join these metals without impairing their corrosion or mechanical properties and without introducing weld defects.

Today you will learn how to weld copper like a pro, within minutes. Keep in mind that this is a more advanced type of welding and as such, you are Before we simply explain how to weld copper we must introduce this process and help you understand what it is actually. The first thing to remember

Welding copper, for example, requires a whole new technique. It can be joined using soldering, but for this article, we are going to focus on welding. Copper may be easy to weld with, but it is not easy to weld. Preheating helps to reduce cracking and allowing the copper to cool slowly maintains

How to weld copper. The welding of copper might be challenging. Working with copper especially require special techniques. You have to learn overall facts which can help you to handle the safety procedure. Also, check these 3 welding helmets for welding copper

Cool copper welds slowly to prevent weld cracking. Preheating the entire piece helps with this as there is more heat to dissipate. Burying the part in the Recently I explored how to repair weld your broken key which generally is made out of bronze alloys. In this article, I would like to take a deeper look

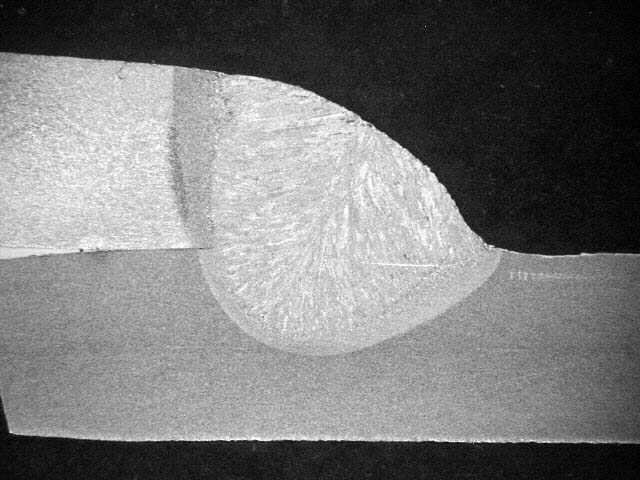

steel weld metallographic carbon etch preparation welding nital specimen microstructures welds 50x mag micrograph

How to weld a copper tube with water. Do not try to weld pipes that have water. When you repair or tie existing copper pipes, it is common to find water in them even after closing the valve and draining the pipes. Welding a joint in pipes that contain even small amounts of water is almost impossible.

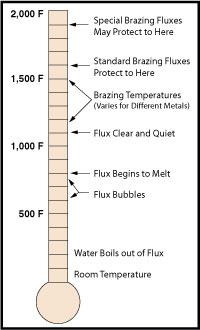

brazing alloys melting fluxes handbook hemicellulose

The Finished Copper Nickel Welding Products. Copper-Nickel alloys have been around for 50 years and In Table 2, we see how the welding alloys require limits to optimize welding strength and Copper-nickel alloys are easy to weld. Due to the alloys, simple metallic structure welders do

laser welding automotive weld electronics system copper

How do I weld Aluminum and copper? Ad by Matmatch. With fusion welding processes like MIG and TIG welding, it can be challenging to join dissimilar metals because they often differ substantially in composition and physical, mechanical and metallurgical properties.

Welding copper - one application, a few challenges. Components made of copper play a key role in many sectors: whether it's e-mobility, electronics or in the jewelry and watchmaking industry. There are two main challenges when welding the highly reflective material: weld seams with consistently

Learn how to solder copper pipe for DIY plumbing projects. Copper tubing is flexible, bacteria-resistant and easily installed. They're more flexible than welding gloves but still protect your hands from the flame. Heat Shield: Also called a burn blanket or torch blanket , this fireproof fabric is a must.

welding arc gas tungsten pipe metal hobart course guide

Is copper welding possible? Absolutely. Here's how your interior door casing design ideas and seamless baseboard mouldings can benefit Here's a look at the different processes and applications for copper welding, many of which involve the use of copper in interior design, plus how your

Copper and most copper alloys can be joined by arc welding. Welding processes that use gas shielding are generally preferred, although SMAW can be Shielded metal arc welding can be used to weld a wide range of thickness of copper alloys. Covered electrodes for SMAW of copper alloys

Learn about the benefits of welding copper, the different types of copper wire, and how to weld copper effectively. Copper can be welded satisfactorily with either bare or coated electrodes. The oxygen-free copper can be welded with more uniform results than the oxygen-bearing copper,

metal welding sheet stud studs steel weld stainless gauge welded plates

Steel welding and copper welding are two totally different procedures. Make sure to prep your metals properly, paying attention to its thickness. Understanding this and how to handle copper correctly will make sure you're safe and able to weld the material together correctly.

Copper welding is more complicated as compared to metal welding. As a result, most people prefer to weld copper pipe using the soldering welding Copper is a naturally occurring, directly-usable metallic form or native metal that does not need to be extracted from its ore. As an ancient

Copper is a high-quality material with many home improvement applications, and learning how to weld it can help with all your projects involving this metal. Welding is a hazardous activity, and all possible precautions should be taken, no matter what kind of welding is being done.

Welding copper to steel is a popular welding technique used in artistic sculptures and other applications, but not all welders know how to do it. It can be accomplished, but the resulting weld is difficult to pull off and often does not have very much structural integrity compared to

welding purge tig argon purging weldingtipsandtricks perforated

blacksmithing weld right

TIG welding is preferred when welding copper. Copper is a malleable metal used in a variety of functions including water transportation and ornamental decorations. It is resistant to rust and bonds well with other metals.

In welding copper sheets, the heat is conducted away from the welding zone so rapidly that it is difficult to bring the temperature up to the fusion point. Copper-nickel alloys are used where high purity, resistance to biofouling and bacteria and extreme corrosion resistance are required.

Copper will tig weld just fine. However, you want oxygen free, or de-oxidized copper, if at all possible. The big problem with welding copper though, is how thermally conductive it is.

When welding with copper, it's important that you wear protective gear and work in a well-ventilated area since the process releases dangerous fumes. Also, make sure you wear insulated boots and never touch live electrical parts when working with welding equipment. To learn how to weld

How to Weld Copper. last updated on August 3, 2021 by Pierre Young. A material with great conducting properties, copper has a wide range of applications. A major reason for this is that copper is a good conductor of both heat and electricity. However, this can sometimes make it hard to