This guide shows welding enthusiasts the 'know-how' of fixing cast iron with wire feed welders. Thermal stress differential can also trigger a difficult process when using wire feed welders. However, it might be hard to weld cast iron, but not impossible at all.

The wire feed process has become the standard of the welding will find MIG welders in homes, shops, and farms all around the world now because the industry has made these types of wire feed machines less expensive and much smaller than they used to be.

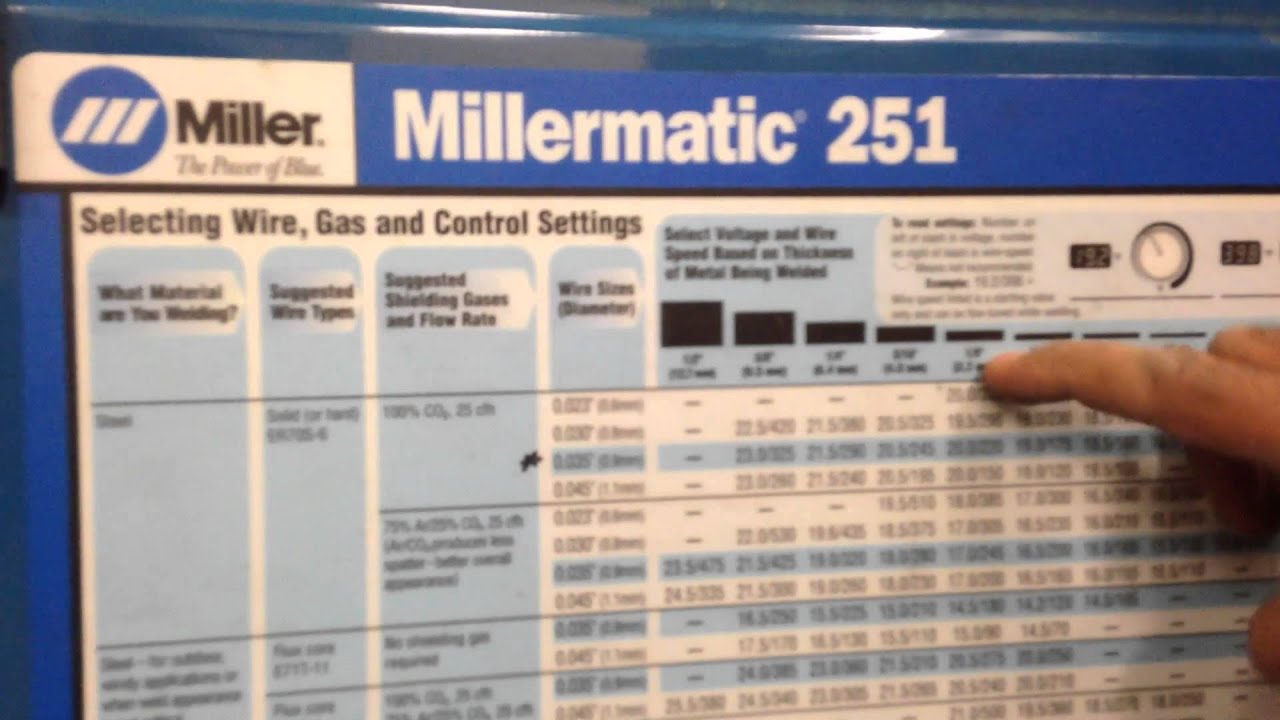

Wire fed welding typically uses a mixture of 75% Argon gas and 25% Carbon Dioxide. In other instances, 100% carbon dioxide is used as the gas shield. How do you calculate wire feed speed on a MIG welder? To calculate your WFS, first measure your workpiece metal's thickness using

What is wire feed welding? How it works. Considerations when using wire feed welders. The welder also needs to use a combination of push and pull techniques to ensure an even and smooth weld. The travel angle remains the same despite the changes in direction as well as the working angle.

welder welders

WG examines, analyzes all How To Use A Wire Feed Welder of 2021. We are happy to provide you with the ultimate selection of the top 10 premium How To Use A Wire Feed Welder.

welder welding homemade wire reels cable wires joining snorkel instructables homemadetools gsaf

In this article, we will see how to use a MIG welder to weld without gas. If you decide to use a regular MIG welder, you will have to replace the wire feed rollers inside the machine with a special type of rollers having groves in them. It's necessary because the hollow flux-cored wire is a lot softer

· Wire feed welders use a continuous wire electrode on a spool. Rollers in the welder driven by a motor feed the wire at a steady rate through an Sometimes, our solutions for How To Use A Wire Feed Welder may not be the best for some, it is easy to understand because the demand for

welder offerup

mig wire welder settings voltage feed

Wire feed welding is similar to Metal Inert Gas Welding (MIG) and Gas Metal Arc Welding (GMAW). As the name indicates, it uses a wire to join metals. Yes, you can weld aluminum with a wire feed welder. But you have to be extra conscious because aluminum oxidizes quickly in the open air.

Learn To How To Spool a Mig Welder Its Very Easy. In MIG welding you will need to weld different types of metal which also requires specific types of wire electrodes. For example, the ER70S-6 wire should better be used on carbon steel and mild steel while the ER4043 and ER5356 wires are

A wire feed welder is a power tool used for adjoining two metals or thermoplastics. You must be aware of how your tool works and how to prevent damage to you and your unit. With this particular tool, an expert advises welders to not keep the unit running for more than the allotted time span as

Solid Wire Versus Flux-Cored Wire: When to Use Them and Why. Print Article. Share. Deciding which welding process to use can be challenging. Learn the basics of solid and flux-cored wire — and how to maximize the benefits of each. Comparing the advantages of MIG and flux cored.

Wire Feed Welders Top Selected Products and Reviews Hobart 500559 Handler 140 MIG Welder 115V by Hobart 15 new & used offers from min How Does A Wire Welder Work? A wire welder works by first installing a roll of wire into the machine, and when you press the trigger on the MIG

Correct adjustment of Mig Welder Wire Feed Roller Tension is vital for long term reliability. This easy to follow blog article explains how to get it right. If the tension is too great, unnecessary strain is put on the Mig Welders Wire Feed Motor and there is a risk of damaging the surface of the Mig Welding Wire.

• Wire - this welder will accept either 4" or 8" diameter spools. Welding wire is susceptible to moisture and oxidizes over time, so it is important to select a ALUMINUM WIRE When using Aluminum wire, it is best to use a larger size tip than the wire size being used. For example: • If wire diameter is .

When you are learning how to use a wire feed welder, it is very important to choose the machine wisely. Choosing an easy machine to start with will lower your learning curve significantly since they are easy to get started with compared to other types of welding like stick welding etc.

Learn how it works. MIG welding uses a machine to feed a wire through a contact tip into a MIG gun. The electrically charged contact tip transfers the Understand the applications. Once you learn how to use a MIG welder, you can make repairs around the home. A MIG welder can be used on

Wire-feed welding is a process that involves feeding the welder wire through an electric circuit to heat up and melt metals as they are welded. Welders often use a foot pedal to control the amount of current flowing through the wire as they weld. The speed at which metal melts is determined by

Wire-feed Welding. Anyone who has experimented with different methods tends to agree that MIG Capabilities of a wire-feed unit center mainly on the question of how thick metal the machine will The author welds two pieces of thin sheetmetal using a portable wire-feed welder. The goal is a

Using a wire feed welder starts with understanding the machine's essential parts and how they work together. Make sure to wear protective gear before you start welding. Also, pay attention to material thickness, wire size, voltage and amperage, and the wire speed to get the correct settings.

Welding a Quarter Panel with a wire feed welder. Your Question,,,i have a 140hd lincoln wire feed welder. I need some welding tips on. how to weld on quarter panels. What do you think will be the best setting and wire to use on it? thank you. Better Mig Ground tip A good ground is really important when using a wire mig welder.

How. Details: A wire feed weld allows a welding enthusiast or a professional commercial welder to make the most types of repair welds and Wire-feed welders employ the use of a ceaseless wire electrode on a spool. Most times, the rollers that are found in the welder run by the motor feed

Want to know how to Use A Wire Feed Welder? Read our components required and steps! Wire feed welding today covers 69% of all welding processes, and the number is growing. Wire feed welding is a process that involves joining two or more metals or thermoplastics using extremely

WIRE FEED WELDING weld that needs to be chipped off. Our recommendation for self-shielding, flux- VARIABLES core steel wire is AWS classification number E71T-GS. SELECT THE WIRE NOTE: WITH FLUX-CORE WIRE YOU It is very important t o select a type of wire that is compatible with

Working outside my shop using a wire-feed welder to join pieces of #9 steel fence wire. Wire-feed welders can successfully joint thin and thick steel. Small, affordable wire feed MIG welder tools are now accessible enough for home hobbyists to buy and use successfully.

Drawbacks Wire feed welders are designed to use a very thin electrode (wire thin) and can't handle thicker electrodes. Wire feed welder with a variable wire speed. Preferably one that can be turned down to 0. Electrode holder. A 200 amp rated holder is plenty.

mig 211 welding welder millermatic miller metal basics using settings wire steel tips beginners correctly melt help advanced machine dial

When using a wire welder the problems of aluminum welding increase because aluminum wire is prone to crumple and bend. Place a spool of 1 mm aluminum wire on the welder and feed the wire into the wire liner. Continue feeding the wire through until it emerges from the wire tip.

welds wire gasless flux welding core mig lap setting weld steel its does without job

Wire-feed welders let you conquer the world of metal, whether you're reattaching the feet to a fireplace grate or fixing the broken axle on a trailer. We tested eight of the best new entry-level welders. They can be plugged into a normal electrical outlet and run without any gas tanks using a process

Wire Feed Welder uses one of the most popular processes of welding, which is known as Flux Coated Arc Welding. Whenever someone wishes to purchase welding equipment, some questions pop into their mind like 'which welding machine to purchase' and 'how to use a wire feed welder'.

Wire feed welding (also referred to as wire welding) offers a number of benefits. First, it provides higher productivity efficiencies over stick since As a rule of thumb, it is recommended to use a MIG process on materials that are 24 to 12 gauge; while flux-cored is only recommended down to 20 gauge.

This video describes how to perform basic arc welding with a Lincoln wire feed welder. Thank you for Support Our Channel by

miller xr wire control feed welders controls