How is stainless steel hardness tested? There are different methods to test materials hardness. When it comes to steels, the most common ones involve indentation resistance, which is tested by using specific materials and shapes such as diamond ball or cone among others.

How To Conduct a Spark Test. You can use either a portable or stationary grinder for spark testing. The Brinell hardness method is similar to the Vickers hardness testing method. The penetrator used in the Brinell test is a round steel ball while a Vickers machine relies on a diamond pyramid.

So which actually works best, when selecting from a bunch of similar steel ?Camera: Nikon L820.

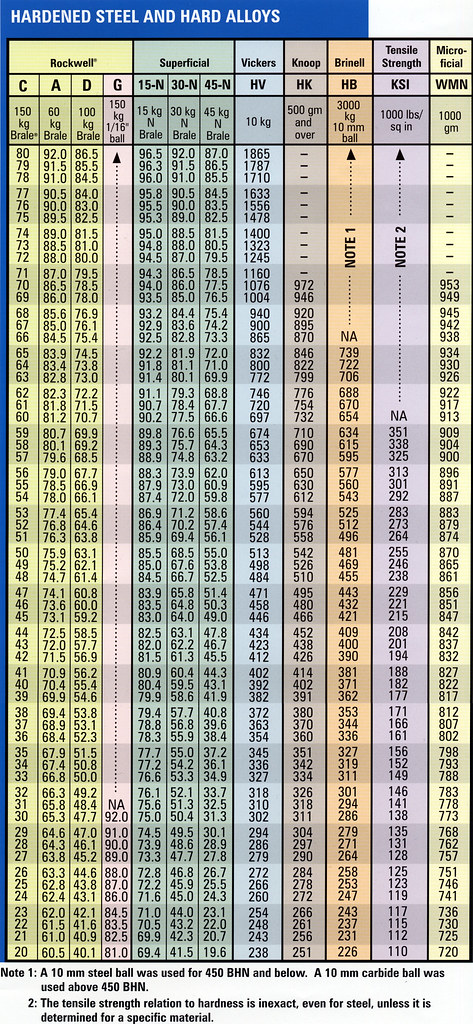

The Rockwell hardness test measures hardness in the simplest way possible: by pressing an indenter into the surface of the material with a specific load and then measuring how There are three methods which are the most common ones to test steels hardness. They are Vickers, Brinell and Rockwell.

The Rockwell hardness tester is essentially a machine that measures hardness by determining the depth of penetration of a penetrator into the specimen under certain fixed test conditions. The penetrator may be either a steel ball or a diamond spheroconical penetrator. The hardness number

Rockwell Hardness Testing Reference Guide. Newage Hardness Testers Selection Guide. #CareForTomorrow - How We Contribute. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method.

Which steel hardness test to use. Traditionally, Brinell is used for softened steels and Vickers is used more widely. These tests measure the diameter of the indentation left on the surface of the metal. The Rockwell method assesses steel hardness by measuring the depth of penetration of an indentation.

hardness brinell testing machine 1st

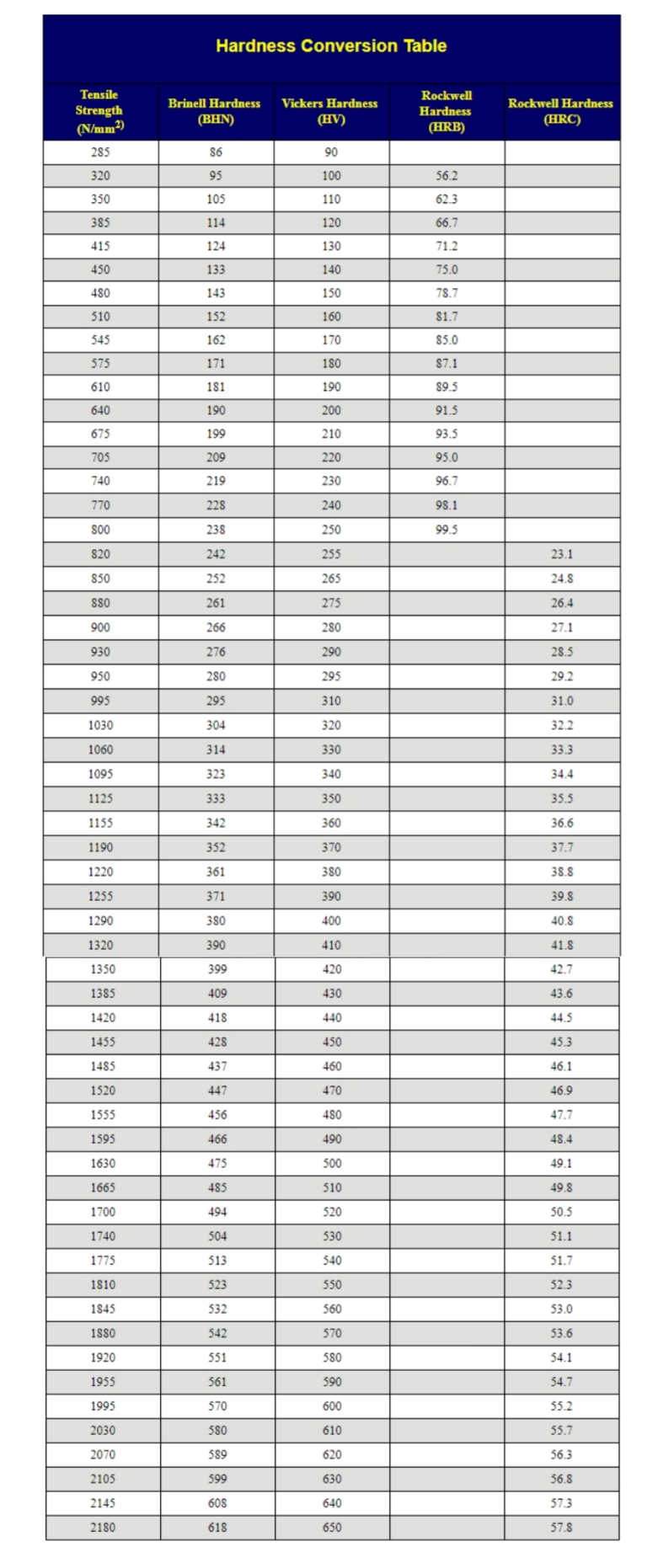

hardness table test brinell conversion hb hrb hv tensile date rockwell bhn vickers formula hard strength section student

Steel Hardness comparison table, with equivalent tensile strength*. *Certain conditions may affect the relationship between hardness and tensile strength. KV Steel Services is a supplier of quality steel to precision engineering businesses.

Brinell Hardness test:- The Brinell hardness test method consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball subjected to As hardness is how well a material hold together when friction is applied, like diamond is the hardest substances known to man, it is

circle circles aluminum steel stainless aluminium disk disc plate sheet press stick cookware non draw 1060 1070 painted okorder exporter

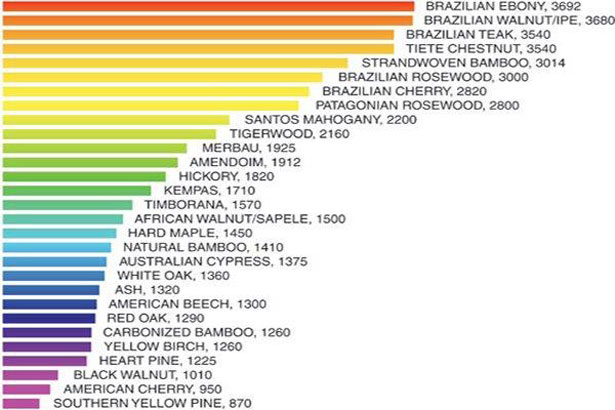

hardness janka scale woods hardwood maple exotic domestic wood chart rating floors flooring floor byhyu rock hard woodflooring different sugar

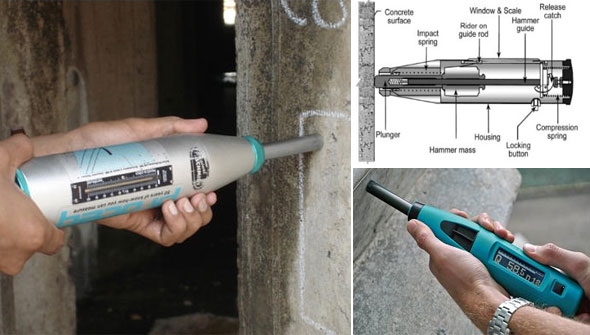

How do hardness tests work? A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by measuring the depth of indenter penetration or by measuring the size

How to Use a Rockwell Testing Machine. Minimum Thicknesses for the Rockwell Hardness Test. A rounded steel ball or conical diamond tip is pushed into the metal, and the depth of the indent is Since the Rockwell test needs to make an indent in the test piece, there's a minimum

mechanical testing laboratory services lab

Hardness test methods. Dr. Dmitri Kopeliovich. Hardness is resistance of material to plastic deformation caused by indentation. Principle of any hardness test method is forcing an indenter into the sample surface followed by measuring dimensions of the indentation (depth or actual surface

hardness metals test metal indentation tests why

How to Test Hardness of a Mineral? The hardness of minerals is measured using the Mohs scale which was developed by the German It has relatively limited use for metallurgists. How to Test Steel and Metal Hardness? Hardness for steel and other metals can be measured using different methods.

The Brinell hardness test consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball subjected to a load of 3000 kgf (29 430 N). For The full load is normally applied for 10 to 15 seconds for harder ferrous metals and for 30 seconds or more for other metals softer metals.

Vickers Hardness Testing. It is the standard method for measuring the hardness of metals, particularly those with extremely hard surfaces Vickers hardness is a measure of the hardness of a material, calculated from the size of an impression produced under load by a pyramid-shaped diamond indenter.

Steel Metallurgist Larrin Thomas uses tests of knife steels to rate the steels and explains the factors that control performance. Knife Steel Nerds. Metallurgy and Testing of Knives and Steel. Toughness is a measure of how much resistance a steel has to fracturing.

The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test This test measures the relative hardness of a material by defining how well it resists scratching by other substances.

What is hardness testing? The Brinell hardness test, Rockwell hardness test, and The Leeb test uses ASTM A956—Standard Test Method for Leeb Hardness Testing of Steel Products. Tables show how tensile strength correlates to hardness for specific materials. This is a useful

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials.

hardness

The Rockwell hardness test method consists of indenting the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under a preliminary minor load F0 (Fig.

friction

Using the Rockwell method to test steel hardness The Rockwell hardness testing of steel parts is done by applying loads to parts via either a tungsten carbide The system has given 20 helpful results for the search "how to test steel hardness ". These are the recommended solutions for your

Even if the steel hardness is known, it is difficult to tell how hard it really is, or whether it has been uniformly hardened across all its dimensions. Also, Rockwell hardness test only reveals the surface hardness of a material and not its internal hardness. Apart from the Rockwell hardness

You'll probably need to do a scratch test to in order to find what minerals are harder than your Next, try to scratch the surface with the sharp end of a steel nail. If it leaves a mark, this means your Although there are other ways to identify a mineral, the Mohs hardness scale is the only way to

Steel hardness describes the properties of steels that resist deformation, indentation, penetration, and scratching. steel hardness is important because According to the hardness of the test material, it is measured by three different scales: The Rockwell Hardness is comprised of three different

Measures of ductility. Hardness testing. Impact test. Fracture toughness tests. Ductility is the capacity of a material to deform permanently in response to stress. Most common steels, for example, are quite ductile and hence can accommodate local stress concentrations.

Rockwell Hardness test is common non-destructive test used in industry. Its principle, Rokcwell scales, procedures and exmaples are shared. Diamond cone or steel ball with four sizes are used as indenters in this tester with 30 different scales. A copper and two plain carbon sheets of steel (

How it works. The Rockwell Hardness test uses a conical diamond or a hard steel ball as an indenter. Initially, a minor load is applied on the metal to be The Rockwell hardness scale, which combines multiple test loads and indenter types, allow the user to judge the hardness of the material using

How to test and compare the results? Hardness is a material's quality to withstand localised deformation. It may be especially important when looking for a suitable material for an environment that includes little particles that can induce material wear.

chart hardness conversion heat strength tensile treating materials flickr testing spidertrax

Best practices for hardness testing including Rockwell hardness testing. Hardness Testing Basics. Hardness, as applied to most materials, and in particular metals, is a valuable With the increasing use of materials other than common steel and brass, as well as requirements to test

Brinell Hardness Test. During this test, an accurately controlled force is maintained when an indenter, generally a carbide ball, is forced into the There is also a Superficial Rockwell, along with a Rockwell Hardness Test. For each individual test, a little load is forced to either a steel ball or diamond