How to test the hardness of metals? - JM Hardness Tester. Affri Portable Metal Hardness Tester Instruction Manual. Economy. Details: metalTest: portable instrument to test hardness with the Rockwell, Brinell* and Vickers* scale The instrument can be used to test most metals: chromed

- There are four typical methods for testing the hardness of metals. These are the sclerometer method introduced by Turner in 1896; the scleroscope method recently invented by Shore; the indentation test adopted by Brinell about 1900; and the drill test introduced by Keep a few years earlier.

rockwell hardness tester wilson number nsmachine

Manufacturers leverage metal hardness tests to determine the material's tensile strength, elasticity, and plasticity. These factors indicate its resistance or The Rockwell Hardness test uses a conical diamond or a hard steel ball as an indenter. Initially, a minor load is applied on the metal to be tested.

Hardness testing machine how to check the hardness of any metal by hardness testing machinemetal ka hardness kaise check karemetal hardness

(i) Brinell Hardness Tester: The hardness test is carried out as follows: The test piece is placed on the top of the elevating screw and the screw is raised. The Brinell hardness number is to some extent an indication of the tensile strength of the metal, which may be ascertained by multiplying the

Rockwell hardness tester gives hardness numbers directly. Rockwell Hardness Test is carried out by making contact of material with the indenter and applying a 10 kg minor load, this results in an indenter to hold the How to Read TTT Diagram and What are the Applications of TTT Diagram?

chart steel hardness conversion reference numbers

hardness water hard drinking soft table due moderately mean deep carbonate east

How to Use a Rockwell Testing Machine. Minimum Thicknesses for the Rockwell Hardness Test. You can buy file kits that will test different hardnesses. The files are heat treated in 5 HRC increments, so you can start with the hardest file and work down until you get to one that skates instead of bites.

How To Conduct a Spark Test. You can use either a portable or stationary grinder for spark testing. In either case, the speed on the outer rim of the wheel Soft metals will result in a deeper impression and low hardness numbers. It is more difficult to make an impression using hard metals, resulting

Hardness is a measure of the ability of a metal to resist indentation. When a metal must withstand forces without depression or denting, a metal with a high hardness In each test of hardness, a very hard object such as an industrial grade diamond is depressed into a material using a known force.

So how can you test the hardness of metals and why is the test so valuable? Rebound Principle There are only two testers for this concept: the Scleroscope and the Leeb. The test consists of dropping a diamond tipped hammer from a fixed height onto a surface to determine the height of

Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. How to determine Rockwell hardness number as per ASTM E18? As per ASTM E18, the indenters can either be diamond spheroconical or tungsten carbide balls.

What is hardness testing? The Brinell hardness test, Rockwell hardness test, and Tables show how tensile strength correlates to hardness for specific materials. This is a useful correlation The development of the hardness test has made it easier for metal foundries to estimate the properties

Hardness, as applied to most materials, and in specific metals, is a valuable, revealing and widely used mechanical test that has been in use in different How Important and Useful is Material and Hardness Testing? Consider the information provided and its importance in structural,

VTSYIQI Leeb Hardness Tester Meter 170 to 960 HLD Metals Durometer Tester HL HB HRB HRC HRA HV HS with Standard D Type Impact Device D Test If I want to suggest some additional views on your How To Test Metal Hardness searching, is it okay? It is so ok, we always welcome all

This test measures the relative hardness of a material by defining how well it resists scratching by other substances. It is for this reason that this test is mostly used to determine only the relative hardness of minerals and not used on other materials such as metals.

hardness shore table testing different material comparison lining monem works anwar hussain published

hardness conversion chart rockwell brinell table vickers tensile postle

Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also The above relative hardness tests are limited in practical use and do not provide accurate numeric data or scales particularly for modern day

How do hardness tests work? A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by measuring the depth of indenter penetration or by measuring the size

In Brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. The applied test force is maintained for 15 to 20 seconds so that the material can settle during this time and the measurement

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. This distance is used to calculate the Rockwell Hardness Number. A variety of indenters may be used: conical diamond with a round tip for harder metals to ball indenters

Rockwell recognized his hardness testing method had to fall within specific parameters. His system replaced earlier metal testing systems, like the older How Rockwell Hardness Applies to Machine Knives. Selecting the right steel strength is vitally important for your industrial machine knives

hardness chart wood janka flooring scale hardwood woodworking charts stability printable drill tap useful ace woods acacia metal tools gun

xrf niton thermo analyzer xl3t goldd

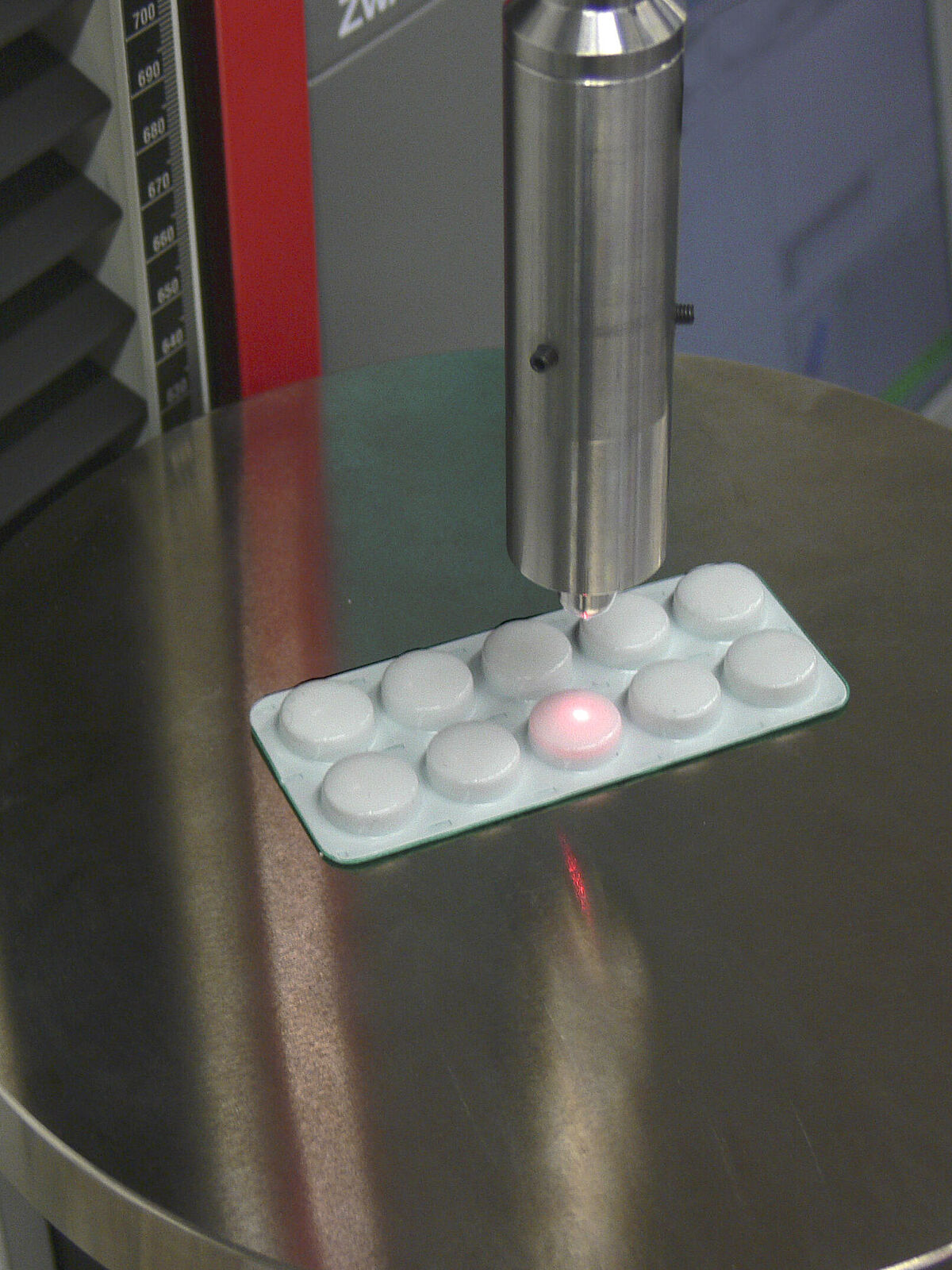

blister zwickroell

Comparing Hardness Tests: Vickers, Rockwell, Brinell, Mohs, Shore and Knoop. Hardness describes the resistance that a material exhibits to permanent There are six main hardness tests that can be carried out: Vickers, Rockwell, Brinell, Mohs, Shore and Knoop. Which one to apply depends on

Mechanical testing of metals is an integral process to establishing how a tested material performs under exacting conditions and whether it complies with There are several different hardness tests and we use the Brinell, Vickers and Rockwell methods. By using Intertek for mechanical testing,

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).

Hardness test results can be extremely useful when selecting materials, because the reported hardness value indicates how easily the material can be machined and how well it will wear. Hardness testing of metals is routinely performed to assess the value of treatments and coatings.

How Do You Test The Hardness Of Metals. How. Details: In the metals industry, the concept of hardness testing can be indicated in a number of ways. Perhaps the most valuable and frequently used evaluation for metals, hardness testing has the purpose of investigating the properties of

chart temper heat metal blacksmith treating forging tools tempering steel iforgeiron knife ferrugem topic tool iron ok general

Laboratory exercise: Brinell hardness test. We will measure the hardness of an aluminum plate. Rockwell test methods are defined in the following standards: · ASTM E18 Metals, ISO 6508 Tensile Properties Tensile properties indicate how the material will react to forces being applied in tension.

How to Test Hardness of a Mineral? The hardness of minerals is measured using the Mohs scale which was developed by the German mineralogist Brinell testing is the oldest method used for hardness testing of metals. A steel ball indenter is pressed on the specimen under a large test

How to test and compare the results? Hardness is a material's quality to withstand localised deformation. It may be especially important when looking for a suitable material for an environment that includes little particles that can induce material wear.

The Rockwell hardness test uses three test forces and three indenters, which have a total of nine combinations, corresponding to nine scales of Rockwell hardness. The application of these 9 rulers covers almost all commonly used metal materials. There are three commonly used HRA, HRB

Rockwell hardness testing machine Hardness. measurement. 4. Reference Test Block It is recognized that Rockwell hardness is often used for testing non-metallic materials such as plastics Bearing metals and other very soft or thin materials. Use smallest ball and heaviest load that does