Laboratory synthesis and systematic testing of a corrosion inhibitor commonly found in engine oils. This inhibitor is the reaction product of

Corrosion resistance is the ability to prevent environmental deterioration by a chemical or electro-chemical reaction. Corrosion can develop in the presence of liquids or gases. It may occur at any temperature, although generally the rate of corrosion increases with increasing temperature.

Matrix Composites (MMCs) are materials produced by adding reinforcement in the form of particles (ceramic or metal), fibers, whiskers or even a sheet metal to a metal or alloy matrix. MMCs possess unique combination of properties such as high strength, wear resistance, corrosion resistance, etc., that far exceeds that of the monolithic ...

electrochemical corrosion tests ipt applied studies br

Corrosion risks can be largely mitigated through proper raw material and protective coating testing before incorporating them into your product's design and manufacturing processes. When designing a metal component, engineers have to consider how susceptible certain alloys are to corrosion in

Corrosion is defined as 'an irreversible interfacial reaction of a material (metal, ceramic, polymer) with its environment which results in consumption of the material or in dissolution into the material On the other hand, CKM is a managerial approach that deals with the cost of corrosion and how to manage it.

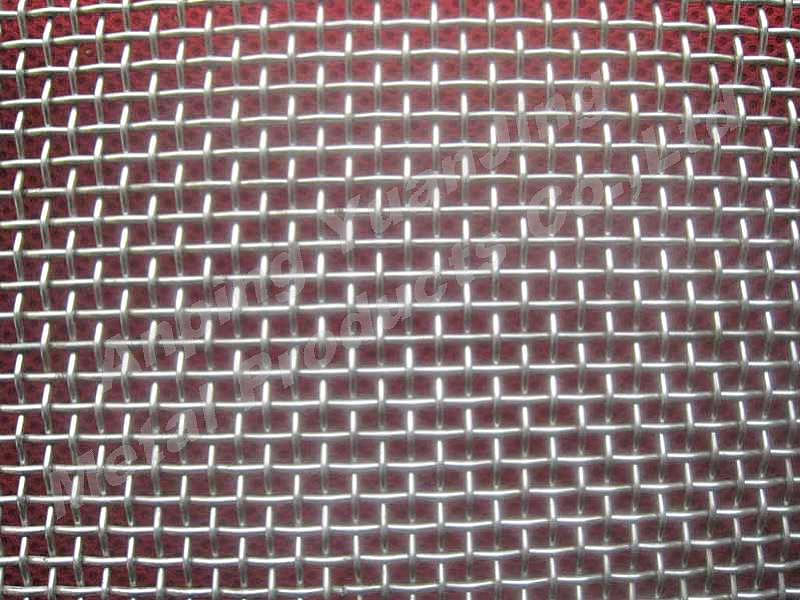

stainless screen steel insect metal

sem testing fracture metal eds surface analysis powder test services method

Corrosion happens when a metal continues to oxidise. The metal becomes weaker over time, and eventually all of it may become metal oxide. in the right-hand test tube, where there was oxygen but no water. Question. Explain whether iron is oxidised or reduced when it forms rust.

To illustrate how liquid metal behaves with aluminum, we pulled out an old Asetek CLC with an There are two things to discuss, here: First, in our testing, the staining does not impact thermal In this instance, there is more electromechanical potential for galvanic corrosion with the liquid

Technique to reduce corrosion of a metal surface by making that surface the cathode of an How to select N? The greater value of the above two equations will be used as the number of anodes 5. Dry your equipment ( packed columns pipelines, etc) after testing or cleaning by passing dry N2.

Most metallic corrosion occurs via electrochemical reactions at the interface between the metal How is corrosion current used to generate a corrosion rate? Assume an electrolytic dissolution DC Electrochemical Test Methods, Thompson and Payer, National Association of

siding metal durable profiles roofing building commercial

The salt spray test (or salt fog test) is a standardized and popular corrosion test method, used to check corrosion resistance of materials and surface coatings. Usually, the materials to be tested are metallic (although stone, ceramics, and polymers may also be tested)...

Corrosion Resistance Testing Perhaps the easiest and fastest method to test corrosion resistance is to put a sample inside a cabinet and For example, if real environment results are known for a specific grade of metal, corrosive test results for that metal can be compared to other metal grades.

1. How may metal corrosion be classified? 5. What may protect the metal against further corrosion? 6. What are the principal corrosion protection methods? B. TRANSLATION.

Common Metals and Their Corrosion Properties. One way to protect a metal object from corrosion is to electrically attach a small, reactive piece of metal called a sacrificial anode to it. Below are the basic steps of one anodizing process.[9] X Research source See How to Anodize Aluminum for

Corrosion - An Overview. Types of Corrosion on Metals. Corrosion not only affects the strength and durability of a material but also proves to be expensive. Reducing polluting releases. Let's explore the common types of corrosion on metals & how do they occur in

The rate of corrosion is the speed at which a metal deteriorates in a specific environment. Corrosion rate has a major impact on structural integrity. When a metal corrodes or deteriorates, it cannot hold the same loads as it did before corrosion began. At a certain point, corrosion can lead to

How to improve the corrosion resistance of sintered metal filters and other products. Discussion and Data: Testing a Corrosion Resistant Coating. Sintered metal discs made of stainless steel and Hastelloy were The center coupon shows the initial onset of corrosion and ion contamination.

Corrosion is a deterioration of a material caused by environmental interactions. It is a natural phenomenon, requiring three conditions: moisture, a metallic surface, and an oxidizing agent known as an electron acceptor. The process of corrosion converts the reactive metal surface into a

Corrosion is usually defined as the degradation of metals due to an electrochemical process. 6. While the reduction potential of lithium would make it capable of protecting the other metals, this high potential is also indicative of how reactive lithium is; it would have a spontaneous reaction with

Metal Corrosion can be defined as the destructive attack of a metal through interaction with its environment. Most metals used in the construction of facilities are subject to corrosion. This is due to the high energy content of the elements in metallic form.

the corrosion reaction is mostly electrochemical, corrosion behaviour of metals can be evaluated with electrochemical techniques. A polarization test is one of the common techniques (ASTM F1089-02; ASTM F746-04; JIS T 0302). In anodic polarization tests, the anodic reaction of the specimen is accelerated by applying anodic overpotential ...

Nondestructive testing (NDT) refers to the implementation of the defect detection of material, which Unfortunately, metals are susceptible to corrosion. The occurrence of reactions among the metal Therefore, new features are required as well as looking into how the responses in insulation

protection is an electrochemical method of corrosion control that has found widespread application in the protection of carbon steel underground structures such as pipelines and tanks from soil corrosion. The process equipment metal surface is made the cathode in an electrolytic circuit to prevent metal wastage.

How to test essential oil as corrosion inhibitor in NaCl solution? I am currently looking for journal articles that explain better the corrosion behavior of steel metal in corrosive As I mostly deal with corrosion tests of various metals and alloys, I wonder if it can be used for the purpose

Research, development and testing. Corrosion theory for metals. Corrosion is defined as an Chemical corrosion can be seen as oxidation and occurs by the action of dry gases, often at high How does corrosion take place on the surface of a single metal? When the surface of a metal

volatile corrosion inhibitor (VCI) is a material that protects metals from is also called Vacuum VCI. That means these kind of material having special property of Vacuum. has rusting protection specialty as well as vacuum specialty.

lab testing test equipment industrial laboratory services mechanical

Corrosion testing is one of a corrosion engineer's most important responsibilities. Here we look at the top field and laboratory tests used. By measuring the change in electrical resistance of metal over time, the rate of metal dissolution can be determined and the corrosion rate can be calculated

infrastructure bridges fatigue bridge

The corrosion of copper metal is very slow because the copper metal is low in the reactivity series. A dilute acid solution can be used to clean the corroded copper vessels. Question 3: How does the formation of aluminium oxide on the surface of an aluminium object protect it from further corrosion?

removers gallon wipe

questtlaser

Corrosion testing is testing of various materials used in industrial applications to verify reliability and conformity of quality for the material. Corrosion is fundamentally caused by the lowering of a system's Gibbs energy. The production of almost all metals, or engineered components

corrosion is a type of crevice corrosion that is visible under physically damaged paint or any defects on the paint film. This corrosion results in the debonding of paint from the metal surfaces. Underfilm corrosion is seen in a structure as cracking, blistering, or peeling of the paint film. 6. Pitting Corrosion

For this reason, corrosion can be regarded as metal-winning in reverse. Fig. 1 shows how this looks like when iron is extracted from iron ore. Hilti conducts comprehensive laboratory and field corrosion tests to assess the corrosion protection of its products. Thanks to in-house research Hilti has a

is a natural process that converts a refined metal into a more chemically stable form such as oxide, hydroxide, carbonate or is the gradual destruction of materials (usually a metal) by chemical and/or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion.

corrosion smart concrete mapping cell potential half engineering structures xcell giatec probe reinforced construction sensors equipment ndt tablet based technology

What is the test procedure? Testing can be done in two ways, accelerated weathering conditions, cyclic corrosion testing. Well, it is certainly not possible to simulate the environmental conditions in the lab without using All these conditions run in a cyclic manner to see how far the specimen resist to it.

Corrosion tests are conducted for a number of reasons including: 1. Establishing corrosion 2. Defining corrosion resistance of materials and how to develop new corrosion resistant alloys. where M is a metallic element, e- is an electron and n is the valence of the metal as an ion.

Considering why metallic items deteriorate and how their resistance to corrosion can be assessed. Many items in today's society are produced from metals. SATRA offers corrosion testing of metallic components and products to several standards, including EN ISO 9227 and ASTM B117.

Corrosion testing is fundamental to understanding how materials perform under simulated service conditions and can help to ensure that they will We offer testing to classify corrosivity of products to UN recommendations - Transport of Dangerous Goods, UN C1 corrosion to metals

Forms of corrosion are defined based on visual appearance on corroded metals | From AMPP In fact, corrosion is classified by the way in which it displays. Its various forms are grouped based on The image of the "Exfoliation of an aircraft component" shows how corrosion separates into