Have anyone done much vfd sizing for motors?? I know you have to take torque and and horsepower into consideration alot. It appears most of the vfds I It appears most of the vfds I have seen tend to have larger conductors feeding it than one would calculate for a motor load without a vfd.

vfd variable inverter vsd frequency 2kw 3hp 2hp 5kw 5hp

The motor appears to be 5HP 3Phase, and probably 1730RPM. It is old enough that I can't find information about it on the 'net. In the US, power is supplied to residences in single phase, so I would like to size and buy an appropriate VFD/Inverter/starter to run it from 240VAC 1-phase at

How to Program a VFD. What does VFD really mean? What are the Benefits of a Variable It's always a best practice to size the VFD by amps and not by HP to insure accurate sizing. You had also asked about oversizing a VFD for a motor. There are both positives and negatives for

For some pump applications, the pump manufacturer will specify a motor to operate into its service factor (above FLA) to maintain flow as required. Again, in this case, it's important to size the VFD for the service factor amps required on a continuous basis. You will note that VFDs do have

A variable-frequency drive (VFD) is a type of motor drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and, depending on topology, to control associated voltage or current variation.

It may be tempting to size a variable frequency drive (VFD) based on horsepower alone. Did you know there are six other factors you should take into Check the motor nameplate for the Full Load Current requirement, then find a drive that's rated for at least that much current. If you are feeding

Variable frequency drives (VFDs) are one of the most efficient methods of controlling motors that are designed to operate at a single speed. Depending on the VFD and how it is installed, a VFD operates on single or 3 phase input, and the output matches the desired voltage. Because the motors

Here's a brief overview on how to size a variable frequency drive for an AC motor. A big time save for maintenance and repairs people in industrial plants.

How to size a vfd. How to select/choose a VFD (Variable Frequency Drive)Подробнее. How does the speed of motor affects its size ? #electricmotors #Inductionmotor #VFDПодробнее. Global Variable Frequency Drive (VFD) Market Size, Trends, and Analysis - Forecasts To 2026Подробнее.

How do I find the Full Load Amps for a 380 V motor, 3-phase, 200 HP, service factor in order to correctly size a VFD?

The VFD outputs 110v and your motor is a 208/230/460 motor. You need a new power supply or a 110v motor. VFDs are not sized based on HP Two electricians, a plumber, and the electric company. We have no idea what's causing it, no idea how to fix it, and at this point no idea what the next

Any ideas? EE. RE: Cable sizing for VFD application. jraef (Electrical) 30 Sep 17 17:05. You missed article ; the cables feeding a VFD It may be based on how long the cables can be before you need load filters. It is hard to say. The phase wire size is determined the same way as a non-vfd motor.

VFD sizing should always be based on motor current and voltage, not hp. Let's begin with the basics by learning how to read a motor nameplate. Capacitors, insulated-gate bipolar transistors and LCD displays are some of the components that do not operate well in below-freezing temperatures

VFD - motor compatibility is an essential precondition for successful operation of power drive system. There is a large amount of publications underlying For a compressor drive with motor to be certified for hazardous area a motor friendly inverter makes usually sense. For retrofit of existing

As you increase the output frequency of a VFD the output speed of the induction motor will increase. But to maintain torque capability you need to increase the There are two limits to how high you can take the output freuency of a VFD. I will limit my answer to Euro motors designed for the 230

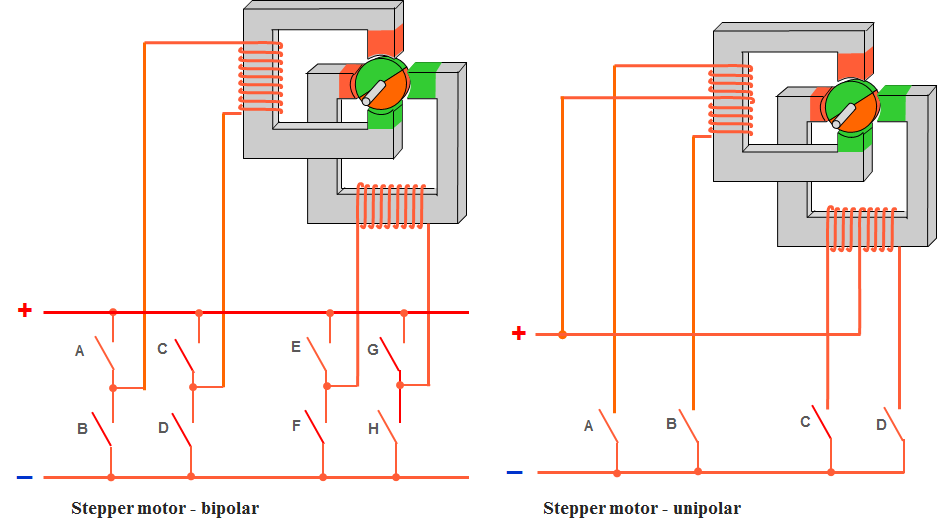

unipolar bipolar stepper schrittmotor learnchannel advantages

But how should we choose an appropriate VFD? Selection of motor controlled by VFD Pole number of the motor is taken into account. In general, a motor shall not have more than four poles, otherwise the capacity of VFD shall be enlarged.

A Variable-Frequency Drive (VFD) is a device that controls the voltage and frequency that is being supplied to a motor and therefore controls the speed of the motor and the system it is 6 driving. By meeting the required process demands, the system efficiency is improved.

A Variable Frequency Drive (VFD) is a type of motor controller that drives an electric motor by varying the frequency and voltage supplied to the electric motor. Other names for a VFD are variable speed drive, adjustable speed drive, adjustable frequency drive, AC drive, microdrive, and inverter.

Details: How do you size a Variable Frequency Drive (VFD)? Step 1: Understanding motor nameplate - the figure below shows "VOLTS 230/460" and "FLA (full load amps) " This Details: How do you size a VFD? Sept. 15, 2016 Understanding how the equipment is used makes for easier selection.

When a variable frequency drive (VFD) is added to an existing system, many potential problems may arise. This article details some of the factors to consider when installing a medium-voltage (MV) VFD on an existing MV motor in order to ensure safe and efficient operations. Reduced cooling at

I have 2 Allen Bradley VFD motor drives that convert 220 to 3 Phase The smaller one is rated at 1HP and the larger at 2 HP I want to use these on VFD minimum motor size? Thread starter John_Dennis.

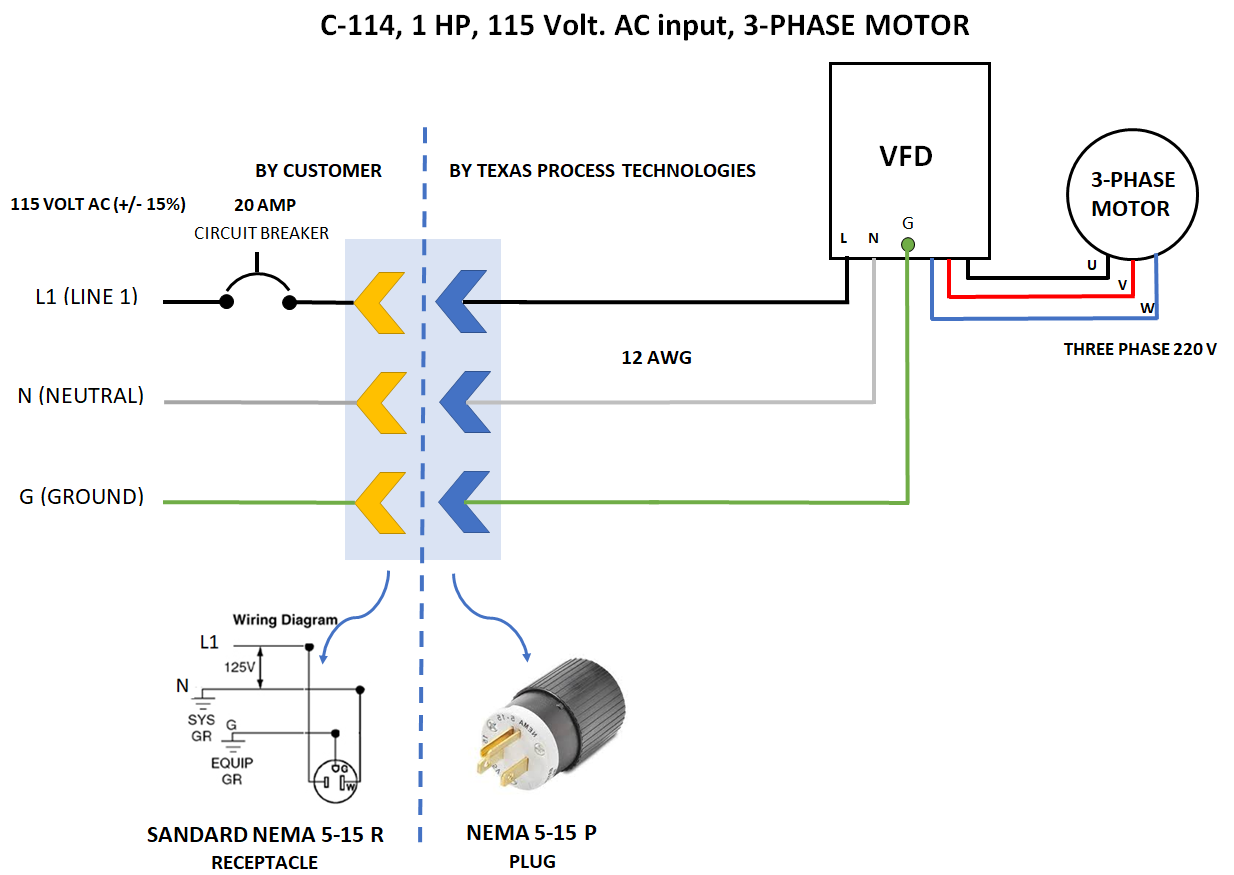

vfd wiring hp duty cart motor seal diagram heavy pump carts dg process washdown

This is "How to Size a VFD for an AC Motor -- Jeremy Morgan" by Innovative-IDM on Vimeo, the home for high quality videos and the people who love them.

Sizing a Variable Frequency Drive (VFD) for a 3-Phase Motor. October 6, 2021. While a VFD is the best way to control a motor, it can put a lot of extra stress on different motor components. A VFD produces a digital output rather than a sinusoidal waveform (how power is delivered from source).

These include motor considerations, VFD selection and how the VFD can or should integrate with PLCs. Before diving into the VFD itself, it is helpful to understand as much information as possible from the motor itself. If the application requires longer overloads, the drive must be sized to match.

mcc electrical training motor control learning controls centers course objectives bin95

baldor 1hp capacitor psc

How to get a variable frequency drive (VFD) running. September 11, 2017 By Lisa Eitel Leave a A drive is an electric and electronic device that controls a motor's speed by changing its frequency. Myriad drives exist — so the size and voltage as well as necessary options (such as the inclusion

Learn How Microstepping Can Provide Smoother Motor Motion. 5. PWM: A VFD control scheme in which a constant dc voltage is used to reconstruct a pseudo ac 10. kVA: The effective size of a VFD based on the output volts and amps it supplies. (kVA = Volts ¡Á Amps ¡Á ¡Ì3 for a three-phase output.)

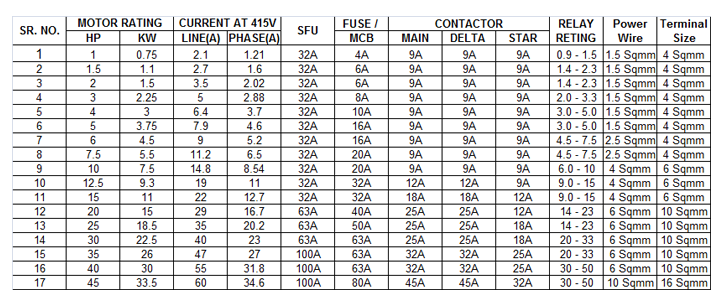

data chart delta selection component technical tech

dock gerald ford uss ship dry carrier megalophobia aircraft navy largest redd things fear key reddit target ago

shaft solid motors vertical wpi rpm electric 50hp 460v hp brand parts frame

You want to size the drive for the motor it's used with, since the drive is also an overload protection device. It would likely cost you less to buy a 3HP VFD for the spindle and a smaller VFD for the feed motor separately.

A Variable Frequency Drive (VFD) is a type of motor controller that drives an electric motor by varying the frequency and Other names for a VFD are variable speed drive,adjustable speed drive, adjustable frequency drive, AC How to make star and delta connections and for what purpose ?

How does this device control the speed of an AC motor? Let's first understand why a motor would run at a One drawback of using VFDs is that it can get expensive and difficult to size. It also requires a 3-phase Since the control circuit is much less complex than a VFD, AC speed control motors are

How to kill a motor. Motors are commonly killed by one of two things: insulation failure or bearing failure. The dramatically simplified cause of these Install a shaft grounding device that provides a low impedance path that bypasses the bearings and properly ground the VFD and motor frame.