table side bar counter cash delfield buffet register portable rod bus radius muncie usd sku bushing

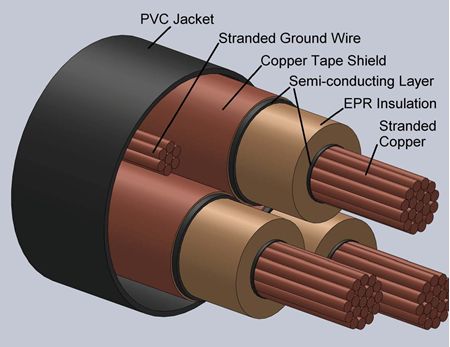

epr power cables 15kv 3c cable wire mv 5kv larger

You want to size the drive for the motor it's used with, since the drive is also an I hook a VFD to the main power input to the machines panel, and use all the Programming is simple, once one figures out how to scroll through

coleco arcade mini tabletop donkey kong games 80s

How do you size a Variable Frequency Drive (VFD)? - Elite ... Education. 1 week ago Feb 27, 2019 · How do you size a Variable Frequency Drive (VFD)? Step 1: Understanding motor nameplate - the figure below shows "VOLTS 230/460" and "FLA (full load amps) " This indicates that the

How do you size a Variable Frequency Drive (VFD)? - Elite. Convert. Details: Again, in this case, it's important to size the VFD for the service factor amps required on a continuous basis. You will note that VFDs do have overload ratings, however these mean the VFD will be running its intermittent

Again, in this case, it's important to size the VFD for the service factor amps required on a continuous basis. Some manufacturers provide specific VFD units designed for this and UL listed, while others do not. Ensuring to use the proper, fully tested UL VFDs is critical for safety and integrity of the system.

VFD is the short form of a Variable Frequency Drive or adjustable frequency drive. The frequency determines the motor RPM and by controlling the AC frequency the motor RPM can be controlled. noise generation in the driver circuit. solution. How to select VFD for my Application?

KEB has a suggested practice for how to reform VFD capacitors given a certain amount of non-powered storage time. These storage reforming procedures are found in the respective power stage manual for each VFD housing size. The longer a VFD sits without external power, the more

How do you size a Variable Frequency Drive (VFD)? - Elite. Install. Details: With all these factors to consider for your VFD sizing and installation, it's important Sizing - The size of the power wires and fuses that are going to the VFD should be sized to handle the overall load and voltage rating of system.

rockwell mill milling machine vertical knee horizontal 2500 fl thread

This is "How to Size a VFD for an AC Motor -- Jeremy Morgan" by Innovative-IDM on Vimeo, the home for high quality videos and the people who love them.

Details: How do you size a Variable Frequency Drive (VFD)? Step 1: Understanding motor nameplate - the figure below shows "VOLTS 230/460" and "FLA (full load amps) " This indicates that the motor uses FLA at 230 Volts AC while using only FLA at 460 Volts AC.

How do you size a Variable Frequency Drive (VFD). Again, in this case, it's important to size the VFD for the service factor amps required on a continuous basis. You will note that VFDs do have overload ratings, however these mean the VFD will be running its intermittent output current rating - which

Hacking The VFD Display - The Hard Way. A bit of theory: I think it is helpful starting off by telling you how a vacuum fluorescent display works. The picture above shows you how to drive the VFD display the least complicated way I could find. Any general purpose NPN would work in this case.

A variable-frequency drive (VFD) is a type of motor drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and, depending on topology, to control associated voltage or current variation.

Learn about various variable frequency drive options. Find out what to consider when looking for in a VFD and what features you should look for depending on your A good VFD will be reliable and easy to operate. Ultimately, it will save money on utility payments, equipment repairs and replacements.

Variable frequency drives are significantly derated for single-phase operation. The altitude at which you're using your VFD also has an effect on cooling. As the altitude increases, the air becomes less dense. This decrease in air density decreases the cooling properties of the air.

Details: How to Size a Variable Frequency Drive. When sizing a Variable Frequency Drive (VFD), the most important consideration is to match the size of the VFD to the AC induction motor.

booth exhaust paint types rear spray 1426 dd draft down booths automotive fans air re industrial many uses credit

fire bells memorial department truck bronze firehouse bell plaques firefighters award anaheim badge retirement cast

Having trouble finding the right VFD for your job? Call 800-800-2261 to talk to a sales engineer!Our VP of engineer Craig Hartman will walk you through

I only specified VFD sizes using the motor's SF if it was absolutely necessary for the application, otherwise I just leave it as a safety factor in the design. Different motors require different overload times. Also when specing a vfd make sure that the pump is not designed to operating in the sf

I've seen less expensive Chinese manufactured VFD's on ebay, but there's typically no consultation with the vendors, and caveat emptor. I have seen recommendations for sizing at multiples of up to 6 or 8 times Full Load Amps. Also I've seen it said with 1 to 2 HP motors that 2 x FLA is sufficient.

These guidelines dispel the confusion about matching variable frequency drives (VFD) and motors to fans and pumps that are typically encountered in commercial building applications. Ask an engineer the purpose of a variable frequency drive (VFD), and a common answer would be "to save energy."

Confusion often surrounds the proper sizing of variable frequency drives (VFDs), and sometimes, knowing when and how to choose one may be difficult. Actually understanding what a VFD does might make this decision easier and the requirements less difficult to understand.

A thorough understanding of how to match the VFD to the driven load is the key to a successful application. How do you size a VFD drive for an application and feel confident it's going to work? First, you must understand the requirements of the load.

Having trouble finding the right VFD for your job? Call 800-800-2261 to talk to a sales engineer! Our VP of engineer Craig Hartman will walk you through how to find a VFD based on your motor name plate in this short and sweet video.

data tech cable chart selection technical

grinder 2x72 belt motor vfd sander

Details: How do you size a Variable Frequency Drive (VFD)? Step 1: Understanding motor nameplate - the figure below shows Details: Before sizing a variable frequency drive Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment,

vfd connection diagram motors need

The VFD outputs 110v and your motor is a 208/230/460 motor. You need a new power supply or a 110v motor. VFDs are not sized based on HP, they should be sized We have no idea what's causing it, no idea how to fix it, and at this point no idea what the next step even is. Any help would be amazing.

For designing the proposed 3 phase VFD or variable frequency drive circuit the following fundamental circuit stages are essentially required How to Set Up the proposed 3 phase VFD circuit. Also for a standard 3ph motor we don't need more than let's say 100Hz, let's limit the pot size.

We all know how important a VFD is to run a variable-speed motor. The use of electronics in it greatly helps in controlling the overall aspects of a motor. This will increase the size of the VFD, as now the current rating has increased with increased HP. This concept is called upsizing of VFD (promoting

Proper VFD sizing. This may be a dumb question, but do you try to nail the VFD size on the head or go up a size? I can see the value in going up a size of For sizing these we use a Siemens tool called SIZER (appropriately). When using this tool we are sometimes shocked as to how much we

How to size a vfd. How to select/choose a VFD (Variable Frequency Drive)Подробнее. How does the speed of motor affects its size ? #electricmotors #Inductionmotor #VFDПодробнее. Global Variable Frequency Drive (VFD) Market Size, Trends, and Analysis - Forecasts To 2026Подробнее.

Sizing a Variable Frequency Drive (VFD) for a 3-Phase Motor. October 6, 2021. While a VFD is the best way to control a motor, it can put a lot of extra stress on different motor components. A VFD produces a digital output rather than a sinusoidal waveform (how power is delivered from source).