heat shapes gasket exchanger exchangers typical styles exchange

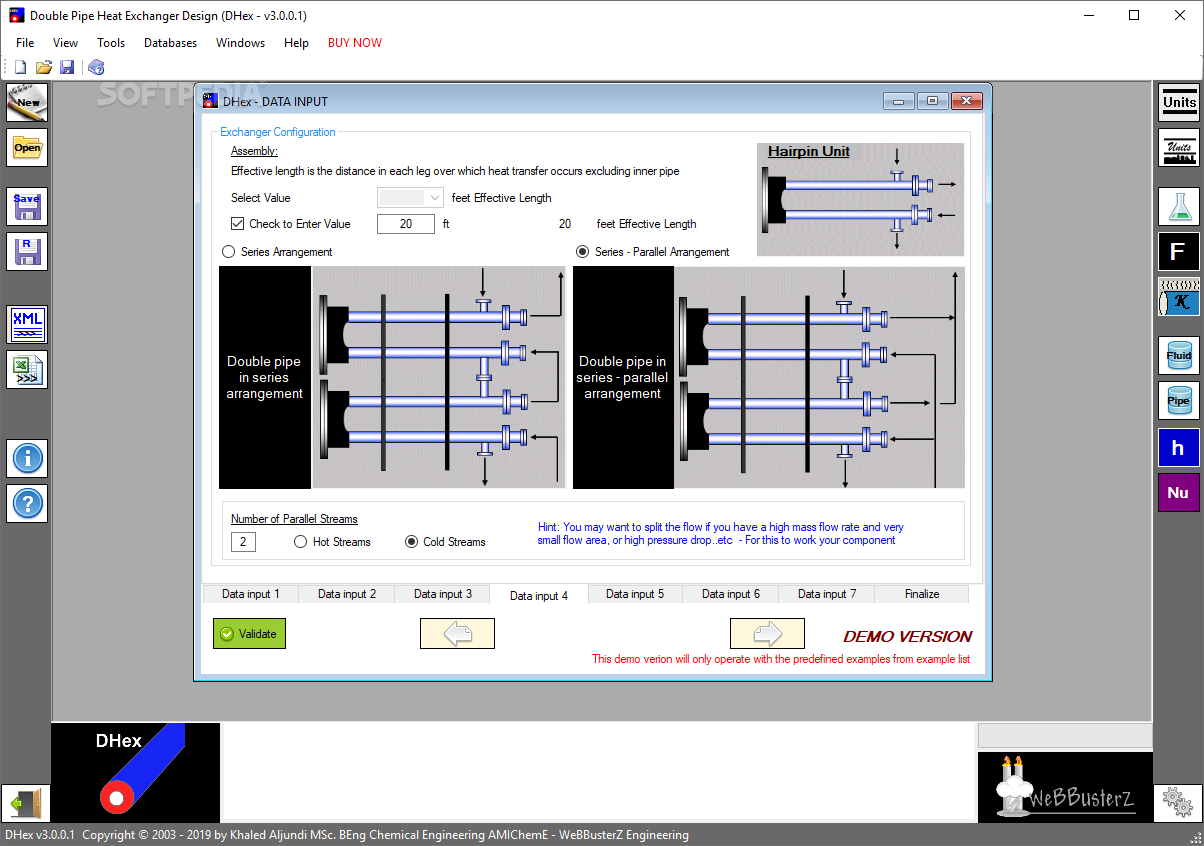

exchanger heat double pipe

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes.

Heat exchangers are devices designed to transfer heat between two or more fluids—, liquids, vapors Further detail on how these components function within a heat exchanger will be provided in the next Size Limitations. After choosing the optimal type and design of a heat exchanger,

Sizing of heat exchangers is done based on the required surface area for heat transfer. There is a design equation (a power law with exponent ) for heat exchangers that can found in the textbook by Peters, Timmerhaus, and West entitled "Plant Design and Economics for Chemical

Lets assume an exchanger that is 100% efficient (no heat loss). Duty (Q) and LMTD is known. Your overall heat transfer coefficient (U) is dependent on Related Threads on How to size a heat exchanger?

30d ikayaa 1800w knsing heizungs elektrokamin kamin einstellung

In this heat exchanger design and sizing calculation example problem the heat energy balance equations and thermal / cooling load calculation equations will be used along with LMTD to find out the design heat Procedure of Heat Exchanger Design and Sizing Calculation Simplified with Example.

...when it comes to choosing a flat plate heat exchanger for a hydronic heating installation that includes cast iron rads and infloor piping. I want to make the exchanger bigger, but how much bigger is prudent? Is there any difference in

Heat Exchanger Design: How Is a Heat Exchanger Designed? Plate heat exchangers also offer other considerable benefits. Because a plate heat exchanger keeps incoming and exhausts air supplies separate, there is Finally, plate heat exchangers are available in a range of different sizes.

To size a heat exchanger, I need to know (among other things) the Reynolds number (Re) as an indication of the flow conditions. Here at , I am not looking for an in-depth examination of the beauty of the Navier-Stokes equation, but for a practical approach to sizing a heat

So how do you determine which heat exchanger is best for a particular application? The choice of a heat exchanger generally ties directly to the type of system to be cooled. That means you have to take into account vital parameters like heat load, available space, environmental conditions, power

Sizing a heat exchanger according to temperature, pressure, fluid properties, viscosity, head loss, thermal performance for industrial applications. For sizing a heat exchanger, several thermal phenomena should be considered first: Forced convection of both fluids: Convection is the transfer

For example: A heat exchanger with a single pass shell and multi-pass tube is defined as a 1-2 unit. APPENDIX II CC-THERM USER GUIDELINES Design Optimisation CC-THERM always searches from a small size to a large size which ensures the minimum possible excess area consistent

Sizing Heat Exchanger - posted in Process Heat Transfer: Hi, I want to design a heat exchanger to cool GLP(it's a mixed mainly propane and propene) from °F to °F using propane at 15°F. The unit is to How can I start the design? How can I determined boiling coeficient? Thanks in advance.

I need to size a condensing heat exchanger for walk-in freezer 3840 at -4 F (-20 deg C). Heat load comes at The ambient at site is 30 deg C. Also how will we know the flow rate of refrigerant on both condenser & evaporator heat exchanger.

In this post we'll focus on design options, and how to size a condenser. Standard Arrangement Option 1: Boiling Under Reflux Distillation with Coil Heat Exchanger. Overhead features: This apparatus includes a coil heat exchanger that enables uprising condensation.

HVAC Heat Exchangers, learn how heat exchangers work with 3D models and real world examples of how they're applied to HVAC applications for air Danfoss heat exchangers increase efficiency, reduce refrigerant charge, and save space in your HVAC system. You can find the entire range

Basic Types of Heat Exchangers. • Double-Pipe heat Exchangers • Shell-and-Tube Heat Exchangers • Compact Heat Exchangers • Gasketed-Plate Heat Exchangers. Selection of Tentative set of Design Parameters •Type of heat exchanger •Initial size of heat exchanger.

60hz conditioners

exchanger

manchester stove wood hearthstone brown

pellet fireplace burning inserts insert door hearth ef3 enviro stove installation zero heat pad handle tri

A heat exchanger involves two flowing fluids separated by a solid wall. Heat is transferred from the hot fluid to the wall by convection, through the If the exchanger type and size are known and the fluid outlet temperatures need to be determined, the application is referred to as a performance

Heat exchanger designs vary based on throughput, thermal duty, local maintenance requirements, size requirements, heat transfer media, the chemical state of the materials (liquid or gas) and physical properties of the materials (, specific heat, viscosity, specific gravity, fouling factors).

TLM = Log-Mean Temperature for Heat Exchanger (K). How do I determine a decent value for U? (Seems super difficult to get a good value by trying to Best way to size an exchanger is with Aspen or HTRI. I doubt you have those. If you want to spend 200 hours doing it in Excel, wolverine

Equations for the shell and tube heat exchanger design calculations to get - overall heat transfer rate, LMTD, heat transfer coefficient etc. In this article, we will take a details look at equations required for shell and tube heat exchanger sizing calculations and design. Shell and tube heat exchangers

With channel partners and customers in more than 80 countries, AFT software has helped companies in many industries design safer, more efficient systems and solve operational problems. Our software can assist engineers analyze, model, and simulation solutions for: Pump sizing | API 610

Typically one ends up with a heat exchanger that is so long that it crosses state lines. After that you are able to design a basic shell and tube heat exchanger. For more detailed construction procedures or if you want to buy some components for your projects, you can contact Alpha Laval or some other

Want to learn more about heat exchangers? What they are used for and how they work? This FAQ page is a good introduction to the subject. What is a Heat Exchanger? Frequently Asked Questions Index; General. What is a Heat Exchanger. What types of Heat Exchanger are available?

pellet stove enviro mini stoves freestanding wood hearth european fireplace envirofire modern pellets thermostat hopper area ft pad heating automatic

In heat exchanger design, there is a trade off between the cost of the heat exchanger, which is a function of the heat transfer area and of the type of As will be seen in more detail in Section , several authors have highlighted how this approach ultimately turns out to exacerbate fouling

How. Details: Heat exchanger sizing and selection requires a combination of knowledge of the heat exchanger types and options as well as knowledge of the application and environment where the unit operates.

Google earch terms: Heat exchanger Heat exchanger selection heat exchanger sizing Heat Exchanger cheresources. how do you know which exchanger/cooler to use? there is a method bases upon Pinch technology. Using this criteria helps you to design a heat exchangers network

furnace carrier reset code gas sometimes heat exchanger oil furnaces heating doityourself air upvote remedies legal

Heat exchanger design includes various aspects, including determination of heat transfer area, choice of heat exchanger type, and detailing of the heat Example #2: A shell and tube heat exchanger is to be used for the light oil cooling described in Example #1. How many tubes of 3 inch diameter

How to calculate a heat exchanger. Starting from the definition of the heat exchanger, the key task for the designer is the sizing of the heat exchanger. The critical issue when designing the heat exchanger is the determining of the thermal exchange coefficients reliably and accurately: a

Two fluids can exchange heat, one fluid flows over the outside of the tubes while the second fluid flows through the tubes. In a fixed tubesheet exchanger, the tubesheet is welded to the shell. This results in a simple and economical construction and the tube bores can be cleaned mechanically or chemically.

These heat exchangers are comprised of multiple metal plates that are typically gasketed together and mounted onto a frame. P&F heat exchangers have high U factors (1000 units or more) thanks to the turbulence produced by the many tight directional changes in the plated channels.