ebara submersible dml sewage pumps pump water pompa industrial channel single clog non waste sales pumping iron cast

How JustAnswer works. Describe your issueThe assistant will guide you. Chat 1:1 with a hvac technicianLicensed Experts are available 24/7. I need help selecting a circulator for heating a 25 x 25 ft room with a radiant manifold using 1/2 pex. There are 4 loops with various lengths, the

Details: How to size a Circulator Pump Each Circulator Pump has several important features, that have to taken into consideration prior to making a purchase. These features include the material of construction (cast iron, bronze, stainless steel), flow rate (GPM, or Gallons per Minute), head loss (

circulator

circulator pumps are typically sized based on the heat load and head loss (pressure drop) for a given zone. Knowing the heat load (in BTU's) for a given zone, allows to calculate the required circulator pump's flow rate in gallons per minute (GPM). For hot water hydronic or radiant heating applications, the following equation can be used:

Centrifugal Pump How Does It Work. 7:19. Simple LED circuit - basic electronics. Fan & motor CALCULATIONS, Pulley size, RPM, air flow rate cfm hvac rtu.

How would this operating cost change if the circuit was constructed of 1" copper tubing rather than 3/4" Assume the circulator's speed could be reduced so that its new pump curve is the brown curve in Separate circulators are required for the distribution system. Several decades ago there was

circulator cpd

circulation circulator npt

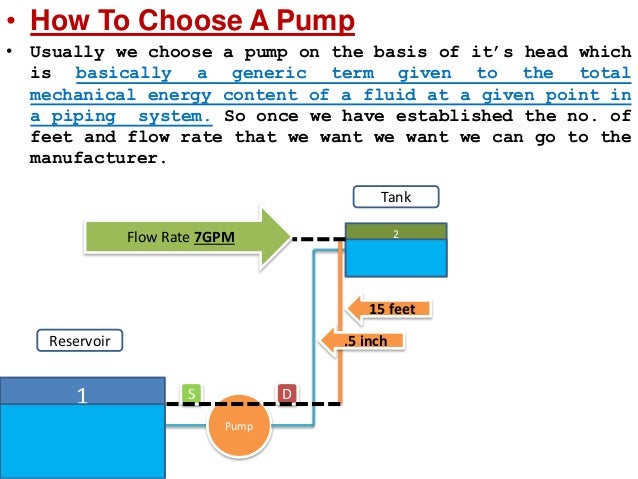

Consult manufacturer pump curves to size a pump according to flow rate (x-axis) and head loss (y-axis). Fittings, check valves, mixing valves, balancing valves, heat exchangers, tubing and other flow-impacting elements should also be taken into account when sizing a circulator pump.

Monday, March 11, 2013. Sizing A Circulator Just Takes Some Math. The dictionary defines a system as a group of interacting, interrelated, or interdependent elements The system's relative success or failure depends on how well these elements work together to perform the system's stated function.

circulator inspectapedia grundfos rené

circulator

This article shows you how to select a Taco circulator that lets the hydronic system you're designing perform as expected. Lowered flow rates often lead to reduced tube sizes and smaller circulators. Look for a circulator with a pump curve passing through, or relatively close to,

Where to Mount the Circulator Pump on a Heating Boiler. Our photo shows the heating zone It is preferable to put a circulator on the output of a boiler, but the expansion tank should be between The circulator operates on a pressure differential and is sized to deliver A: the correct amount of

circulator pump leaks heating pumps heat system repaired un why inspectapedia

and get a pump that can hold that flow, in our case [10K delta] 10kcal/kg or about [ for 20K delta]. how to drain a single loop in one of my heating zones? 4. heating zone stays hot even when the thermostat isn't calling. upgrade circulator pump in closed hot water heating system?

How to size a Circulator Pump Each Circulator Pump has several important features, that have to taken into consideration prior to making a purchase. These features include the material of construction (cast iron, bronze, stainless steel), flow rate (GPM, or …

For details on how we use cookies, collect data, & how to manage your consent please see our Cookie Policy & Privacy Policy. Every 10,000 BTU's of heat load the circulator must output a 1 gallon per minute flow. The minimum flow rate for a circulator pump should be 10 gallons per minute at

pump circulator circulating pumps dultmeier units motor gpm flanged

get a pump that can hold that flow, in our case [10K delta] 10kcal/kg or about [ for 20K delta] [26kcal/ [1kcal/kg K] * [1Kg/L]] of water, then measure maximum water column you need on your system and choose a pump …Reviews: 2

How Does a Circulator Pump Work? Your circulator pump is a primary component of your boiler system. It circulates hot water from the boiler system into the piping of different hot water sources of your home, like the Circulator pumps are small in size, making them harder to repair on your own.

18, 2014 · Then I'd allow 6 feet of pump head for every 100 feet of length in that circuit. Again, this is from Gil's System Syzer. When you're at the maximum normally used hydronic flow through a pipe of any given size, the head loss is going to be 4 feet per 100 feet.

Circulators for heating water without problems. The choice of the most suitable pump is fundamental to ensure a plant flow such that develops the power established at the design stage and for avoid problems in operation.

npshr

centrifugal inline pump exploded circulators rotor pumps wet hydronic

How to size a Circulator Pump. Taco pump curves. Each Circulator Pump has several important features, that have to taken into consideration prior to making a purchase.

Details: How to size a Circulator Pump Each Circulator Pump has several important features, that have to taken into consideration prior to making a purchase. These features include the material of construction (cast iron, bronze, stainless steel), flow rate (GPM, or … › Verified 1 week ago.

All circulator pumps are typically sized based on the heat load and head loss (pressure drop) for a given zone. Assuming that system calls for 100,000 BTU/hr, a circulator pump should have a minimum 10 Gallons Per Minute flow rate at a given pressure drop.

do I size a circulating pump? 1 GPM = 10,000 BTU/hr, meaning that for every 10,000 BTU's of heat load the circulator must output a 1 gallon per minute flow. Assuming that system calls for 100,000 BTU/hr, a circulator pump should have a minimum 10 Gallons Per Minute flow rate at a given pressure drop.

Fitting a circulating pump to your hot water system is not complicated, but you must know how to properly size the pump. Circulating pumps work well with solar panels or with other forms of environmentally friendly heating, so if you have any green living hot water system, fitting one of

circulator pump called working doityourself upvote

58fc grundfos pump ups15 furnace outside wood boiler curve

aquastat pump circulating setting constantly functioning water heating pipe doityourself device surface mounted round

How to size your Pump for an Outdoor Wood Boiler System - Chapter 2. This video discusses the basic function of a circulator in a hydronic system. I discuss pump curves and basic circulator terminology ...

pump recirculation circulator grundfos residential water system pumps installation line plumbingsupply

A "circulator" is a pump but is typically used in a closed circuit, and is usually smaller with a fractional horsepower motor, although that is not always the case. The costs of the VFDs need to be considered but typically are worth the expenditure. How to read pump curves.

circulating 115v circulator recirculating hydronic coupling pumps pompa

circulator

How to do pump sizing by application. Step 1: Define your application requirements. What's the difference between a "pump" and a "circulator pump"? They look the same and they both create a pressure differential to move liquids, but the difference becomes obvious when you look at

Hydronic Circulating Pump Sizing Calculator Economic! Analysis economic indicators including growth, development, Taco pump curves. Economy. Details: Assuming that system calls for 100,000 BTU/hr, a circulator pump should have a minimum 10 Gallons Per Minute flow rate at

A circulator pump or circulating pump is a specific type of pump used to circulate gases, liquids, or slurries in a closed circuit. They are commonly found circulating water in a hydronic heating or cooling system.

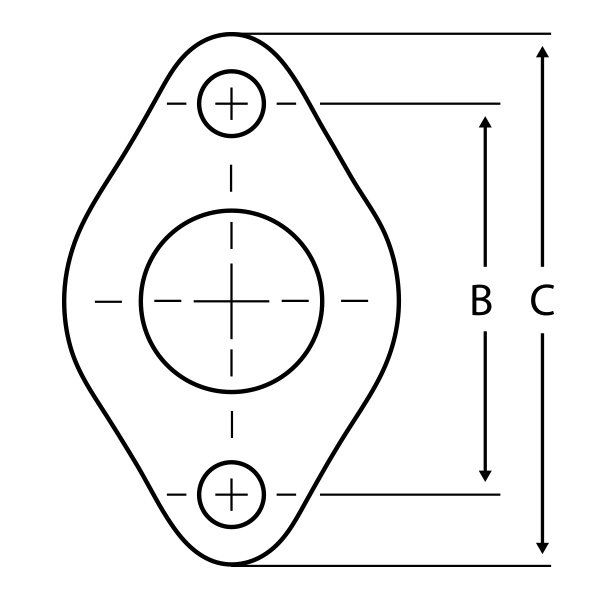

circulator pump flange measure measurement measurements bolt

Home Mechanical pumps Circulating Pump Basics- How a Pump Works HVAC Heating Pump Working principle. Circulating pumps come in many shapes, colours and sizes but they typically look something like these. These pumps are inline centrifugal type pumps which means their inlet

circulator pumps are typically sized based on the heat load and head loss (pressure drop) for a given zone. 1. Knowing the heat load (in BTU's) for a given zone, allows to calculate the required circulator pump's flow rate in gallons per minute (GPM). For hot water hydronic or radiant heating applications, the following equation can be used:File Size: 698KBPage Count: 3

A circulator pump, which, with the exception of the "on-demand" system, constantly circulates a small amount of hot water through the pipes from the heater This begs the question, "shouldn't a contractor know how to accurately size the proper circulation pump?" The short answer is yes they should

› how do rf circulators work. How to Size Circulators - Each Circulator Pump has several important features, that have to taken into consideration prior to making a purchase.

pump water circulation recirculation speed inch npt recirculating heater circulator domestic rs15 120v system gpm circulating happybuy 110v tankless solar

Hot water circulator pumps can be found nearly everywhere with a variety of manufacturers and options to choose from. Many of the earlier circulator pumps worked non-stop and were more expensive to operate because they were constantly using electricity. How to size a circulator

How do I size a circulator, or pump for my system? We offer a document TD10 that can step you through the process of sizing a circulator. The 00 series circulators carry a 3 year (from manufacturers date code) warranty through place of purchase. The manufacturers date code

Boiler Circulator Pump It is important when the circulator pump is installed that the proper size of pump is selected for the amount of flow needed for the. Bell & Gossett Pumps | Boiler Circulator Pump Service and Maintenance. How can I tell if my circulator pump is working?

Circulator pumps are the economical, easy to install, and environmentally friendly answer to waiting for the hot water to arrive where you need it. Sets available for cast iron, bronze, or stainless steel pumps in a variety of pump connection sizes and pipe sizes. Safe for use with potable water systems.

How many times have you heard, "I've been doing this for 30 years. I know how to install a tank!" Choosing a circulator is one of the key pieces behind a successful installation. Selecting the right pump. A lot of boiler manufacturers supply a pump with different boiler models.