Shape-setting refers to the process used to form a Nitinol wire, tube or sheet into a specific and often complex geometry. Whether the Nitinol alloy is to be used in the superelastic or shape memory condition, it is necessary to establish the appropriate heat treatment.

Nitinol's unique properties of shape memory and superelasticity result from a phase transformation within its crystal structure that happens with temperature To demonstrate shape memory behavior you can deform a Nitinol item at a low temperature, really bending it out of shape. Then heat it

Nitinol wire, how to program this shape memory wire and test it. I use a candle flame for programming it and both a candle flame ... Lets see how to shape memory metal and nitional wire experiments This is not a DIY but a demo which shows you every step.

To set shape set nitinol, machined nitinol is constrained on a mandrel, or custom fixture. This mandrel can be made by AMC or provided by the customer. Imbedding an element of shape memory nitinol in the tip of a catheter could provide active, on-demand steering which is why it is often used in

Shape Setting Nitinol. Mon, 2009-11-16 11:44 - offshore. I'm just wondering if anyone knows if there are any guidelines/references on the maximum strain in a Nitinol component during a shape setting heat treatment.

Shape setting Nitinol tubes and wires in a typical laboratory setting for use in superelastic robots is challenging. Obtaining samples that remain superelastic and exhibit desired precurvatures currently requires many iterations, which is time consuming and consumes a substantial amount of Nitinol.

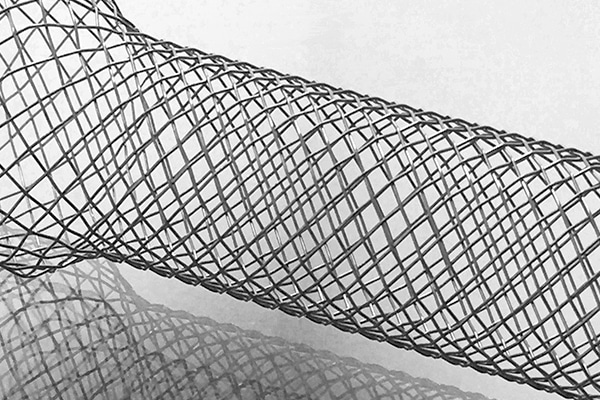

Nitinol Design Concepts. Design, simulation, and analysis resources from Confluent Medical Technologies. Intricate nitinol structures can also conform to complex anatomical constraints, and move with the body in an almost lifelike manner.

To shape set Nitinol, the heat treatment temperature should be above 475 °C with most performed above 500 °C to reduce process time and improve shape retention ( reduce spring back). The actual temperatures and soak times are determined based upon the starting alloy composition and

How to Work with Nitinol: Interesting and Useful Projects You Can Do with Shape Memory Alloy. By Dr. A. D. Johnson, TiNi Alloy Company - Reprinted by If the training limits are exceeded, training will resume to a new set of conditions (unless these conditions are so extreme as to cause failure of

nitinol

nitinol actuator niti inc wires

Basic shape setting: To set the memory shape, you want the nitinol to reach a temperature of 500-550℃ (930-1020℉). If the temperature exceeds Kellogg's Research Labs is an innovative company focuses on Nitinol product prototyping and development. We also offer most varieties of

Setting Nitinol Austenitic Shape. Qwertom (Bioengineer). (OP). This white paper shows how collaborative robots can play a role in helping companies succeed in the Covid-19 world: to help with social distancing, ramp up new lines quickly and reshore existing products due to interrupted

nitinol braiding devices implantable medical braided

nitinol shape memory alloy

Basic shape setting: To set the memory shape, you want the nitinol to reach a temperature of 500-550℃ (930-1020℉). ... With profound know-how and dedicated equipment MeKo ensures the precise setting of these sensitive requirements.

Shape-setting refers to the process used to form a Nitinol wire, tube or sheet into a specific and often complex geometry. Whether the Nitinol alloy is to be used in the superelastic or shape memory condition, it is necessary to establish the appropriate heat treatment. Is Nitinol stronger than titanium?

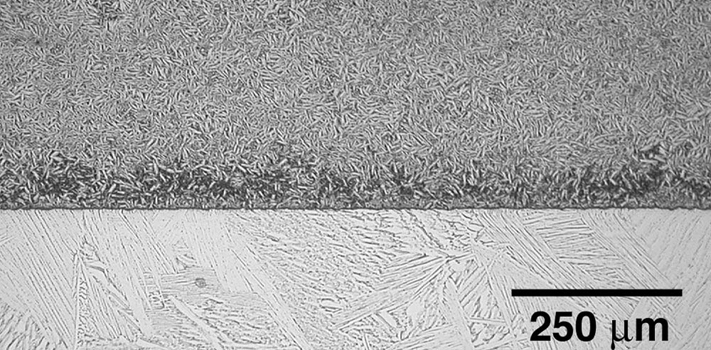

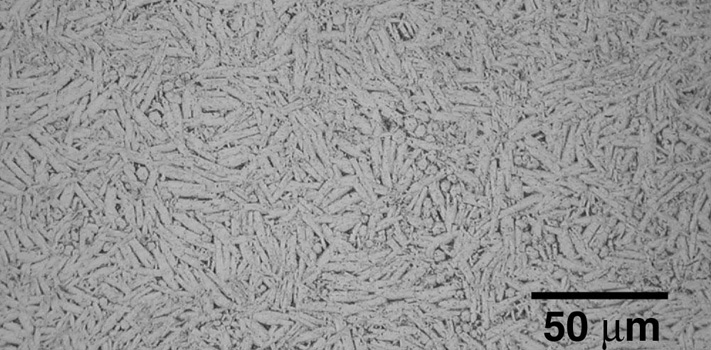

called Nitinol, derived from Ni-Ti-Naval Ordnance Laboratory. Until now, Nitinol is still the alloy showing the best Shape Memory characteristics. In this section, the fcc + bct transformation occurring in steel is used as example. How-ever, most SMA's have a bcc structure in the

Nitinol shape setting is the process by which the final, specified shape of the metal is configured and programmed. This requires specific thermal processing for each device depending on the end use and end-use environment. Nitinol shape setting must also take into account the desired final condition

nitinol stent shape its metal self expanding braided remembers endovascular surgery

Nitinol is one among many shape memory alloys (SMAs) that have Upper plateau strength, lower plateau strength and the residual elongation (or permanent set) are also recorded. Heat treatment also used to set the final shape in the Nitinol component. If the Nitinol has a reasonable amount

Nitinol wire, how to program this shape memory wire and test it. I use a candle flame for programming it and both a candle flame and electrical current

Shape setting nitinol stents, heat setting medical devices, heat treat/annealing of platinum and stainless steel guide wires, nitinol assemblies Shape Setting Fixture. The excellent heat transfer due to the liquid like properties of aluminum oxide allow heat soak and overall manufacturing time

Description: The instructor introduces Nitinol, a shape memory alloy (SMA). Students explore Nitinol's characteristics in two investigations and design an The instructor introduces students to Nitinol in a PowerPoint presentation. Students then work in teams and use handouts to explore the

Nitinol shape setting is one of the most critical parts of nitinol product manufacturing for surgical devices. It is an important function in the manufacturing process, but one that is not widely available. We are one of very few contract manufacturers offering nitinol shape setting in support of

The Process of Shape Setting Nitinol. Nitinol is a highly shapeable alloy given the right treatment and conditioning. To perform shape setting, you must fix your nitinol material to a solid surface or object. The form must be stable enough that it remains in its desired shape once heat is introduced.

We set the shape during several Nitinol heat treatment and cooling cycles carried out in succession, the last of which determines the final shape of the After the component's shape has been set, we can also set its Af temperature(if necessary) through a precisely controlled thermal treatment in

nitinol shape alloy niti kinetic coatings memory metallization

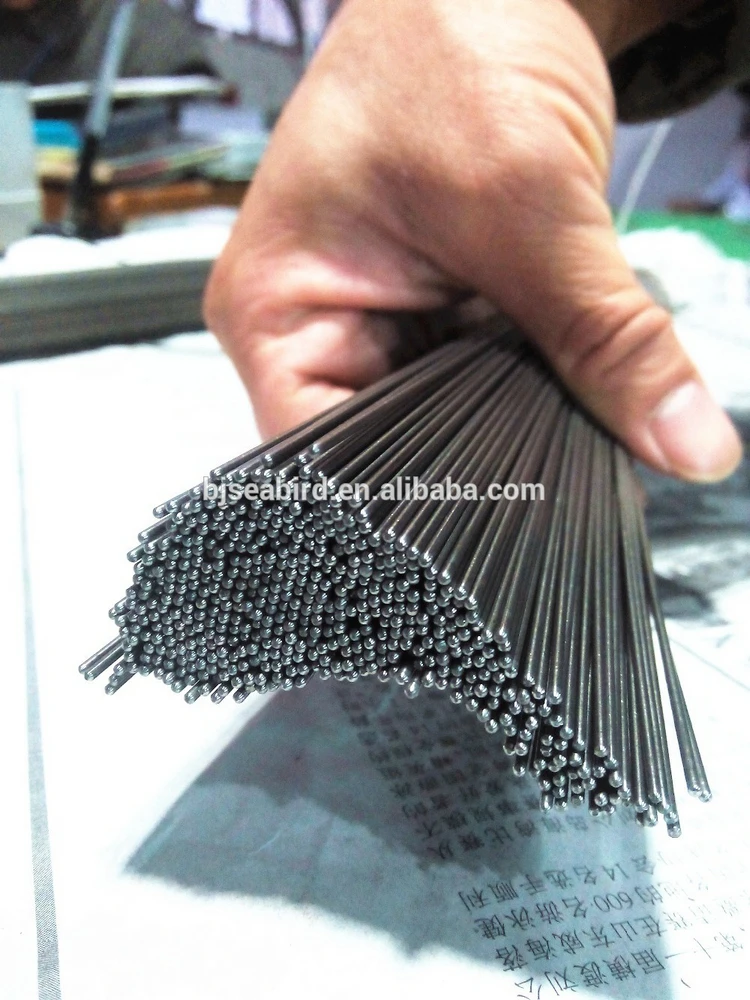

Shape setting is the process of wrapping Nitinol wire around a mandrel or fixture and heat treating at a closely controlled time and temperature to achieve a If your application requires shape set parts, contact us. We also offer shape setting information on the Nitinol Overview Page. We're one of

Nitinol design concepts and examples from Confluent Medical Technologies - nitinol-design- at master Objective: Expand a laser cut tubing component into a complex formed shape, using simulation to replicate the shape transformation in each physical heat

Nitinol is an alloy which is 55% nickel and 45% titanium. This alloy is interesting because it can remember its shape. If a nitinol item is deformed and then heated, the atoms take their initial position, and the shape of the item Homemade barometer How can you make a simple barometer?

The use of a nitinol shape memory or superelastic element for a particular application generally requires the setting of a custom shape in a piece of nitinol. The process required to set the shape is similar whether beginning with nitinol in the form of wire, strip, sheet, tubing, rod or bar.

The sec· and part of this paper wi ll demonstrate the time and temperature effects required to shape·set med· ical devices from the as·received Nitinol wire. In this section we will document the mechanical propcnies from -100 to 200DC 10 illustrate how test tempenlture affects performance.

Nitinol alloys exhibit two closely related and unique properties: the shape memory effect and superelasticity (also called Shape memory is the ability of nitinol to undergo deformation at one temperature, stay in its Nitinol-Tubing. How NASA Reinvented The Wheel - Shape Memory Alloys.

nitinol

alloy nitinol shape coatings kinetic memory metallization

Nitinol is one of the shape memory alloys, which are a fascinating bit of materials science. First, you need to know that many materials and alloys can exist A piece of nitinol is 'trained' by heating it into its symmetric phase and forming it to the desired shape. This is the shape that will be 'remembered'.

Nitinol shape memory alloys have revolutionized many traditional engineering designs with the unique properties of To date, Nitinol provides the best combination of shape-memory material properties for commercial Set-down increased gradually with current and complete set-down was attained at 295A.

medical nitinol wire guide surgical merchandise wholesale grade china superelastic consumables spine