planning method at item/subinventory level = Min-max planning. Min-max minimum quantity specified at the subinventory level = 100. Min-max maximum quantity specified at the subinventory level = 500. If you run the min-max planning report, and specify No to the Net Demand options, Inventory performs the following calculations:

Assembly and BOMSee how inventory tracking keeps you ahead of orders. When deciding on a safety stock level you'll want to consider: average daily sales and the daily Hi Boniface! Sorry, this post doesn't deal with max stock levels, but rather the minimum threshold before you *should* reorder.

Inventory Planning Method: Set to Min-Max. Min-Max Minimum Quantity: Enter the user defined quantity minimum for min-max planning. Subinventory level min-max planning. Oracle Inventory takes into consideration inventory balances, purchase orders, internal order supply and.

06, 2016 · Method. Most employers of this type of system use a semi-scientific or mix of qualitative and quantitative factors to set Min and Max points. Typically, the minima are set by intuition at first, then adjusted to reflect reality as more sales and order data are recorded.

The Min/Max inventory ordering method is a basic reordering mechanism that is supported by many ERPs and other types of inventory management software. This method tracks the current total stock level, which is typically the sum of the stock-on-hand plus the stock-on-order for every single SKU.

wilmar stockroom

Min-Max Inventory Supply Chain Strategies. Minimum level | how to calculate minimum How do people contribute to Howtolinks in order to solve "How To Determine Min Max Inventory Levels "? There will be a section of user contribution to get advice from

inventory

Basically we have requested that minimum inventory levels will be set for the coffee mugs. So I have to configure that and show you how we can actually fetch that information into something Works will with min/maxes and other type of planning scenarios. So if I go in here I can just hit Calculate Plan.

Inventory - Setting Max/Min Levels - The Uniform Solution. Windows. Details: Maximum and Minimum stock levels for a particular style and color are set from the Inventory List in The Uniform Solution.

inventory min max system

28, 2021 · A reorder point refers to the minimum level of inventory that determines when it’s time to reorder inventory. The reorder quantity you set should consider both customer demand and lead times. Most inventory apps also offer a feature that will automatically notify you when inventory levels reach a reorder point. 3. Use an inventory management ...Missing: min maxMust include: min max

Optimal inventory - definition. Target inventory levels. The challenge lies in how to factor confidence, correctly and objectively, into optimal target inventory levels. For example, kanban, min-max and even PAR level are all variations on the fundamental ROP replenishment method -

The inventory levels are reviewed at a set frequency. Depending on specific inventory needs, a In this section, we describe how Streamline drives the replenishment process using the Min/max Max inventory - the maximum inventory level that you potentially can have in stock in the current period.

A min/max inventory system is an approach to managing materials or goods in which the business sets a minimum threshold and a maximum level of inventory to hold. When the current supply of an item reaches the minimum level, a new order is placed.

Making Min-Max Work. While some companies love the concept of JIT (Just in Time), very few companies To increase inventory turnover rates requires the ability to properly forecast customer demand, decrease Finally, at the end of the article is a video about how to calculate a safety

As of July 29, our max inventory level is 1228 , and this is despite the previous 30 days sales The max inventory limitation had dropped to 804 units. A week later on July 29, the sales showed only How would that work? You have two options. One option is to set up a shipment of 200 items

inventory sap management practices minimum maximum data master levels tab seidor fields

inventory max min minimum levels maximum setting goals

10, 2020 · The formula to set min stock level for forced-ordering and continuous review is the same. Here it is: For forced-ordering and continuous review max-min systems, the formula is: Min stock level = lead time stock level + safety stock level. For a standard system, the formula would be: Min stock level = lead time stock level + safety stock level + review period stock …Estimated Reading Time: 5 mins

How to Set Min and Max Inventory Levels for Your Logistics ... Oct 01, 2018 · This is where your inventory min max calculation comes in: determining the level that triggers a reorder, and also the maximum order that you should make.

Min/Max inventory management allows distributors to optimize point-of-use inventory for their customers. By tracking real-time consumption And while simplistic, min/max levels can be adjusted to optimize inventory. The calculation to reorder is simple: it's the difference between the

lean

HELLO, Anybody have experience with setting MIN/MAX inventory levels for consumable material and frequency of renewal? Pretty much a standard Operations Research optimization problem. You are balancing the cost of maintaining inventory with the expected costs of stockout.

1Example 2Example 3The formulas used to calculate the minimum level of stock are given below: Minimum Level of Inventory = (Maximum usage × Maximum lead time) – (Average usage × Average lead time) Or Minimum Level of inventory = Re-order level – (Average usage × Average lead time) Both the formulas are equivalent and produce the same more on

Inventory - Setting Max/Min Levels - The Uniform Solution. Setting max and min stock levels will determine your desired stock level, and when the program automatically reorders Details: Maximum inventory levels is the limit you set for how much inventory you have available at any given period.

Inventory - Setting Max/Min Levels - The Uniform Solution. 6 day ago How to effectively set min/max stock levels . When embarking on a min/max level setting 4 day ago Max / Min Inventory Control System •Set minimum and maximum inventory levels for items you want to keep in stock. •

26, 2013 · How to set your max-min levels for your inventory items.

eg5

29, 2021 · Create a fixed picking location. Go to Navigation pane > Modules > Warehouse management > Setup > Warehouse > Fixed locations. This is an optional task for min-max replenishment, but ... Click New. In the Item number field, enter or select a value. If you're using USMF, you can select item A0001. In ...

05, 2012 · Calculating Minimum Stocking Level. As I described earlier, the formula to determine how many items you need to order goes like this: [Order Qty] = [Min Stock Level] – [Qty Available] So, what is a minimum stocking level? It is the number of items you need to keep on hand in order to avoid running out before you can get more items.

Inventory - Setting Max/Min Levels - The Uniform Solution. Excel. Details: Maximum and Minimum stock levels for a particular style and color are set from the Inventory List in The Uniform Solution.

The Min/Max inventory ordering method is a basic reordering mechanism that is supported by many ERPs and other types of inventory management software. Min-Max is a simple and easy to use inventory management method that does not require specific knowledge.

What is goals and how to differ objectives.

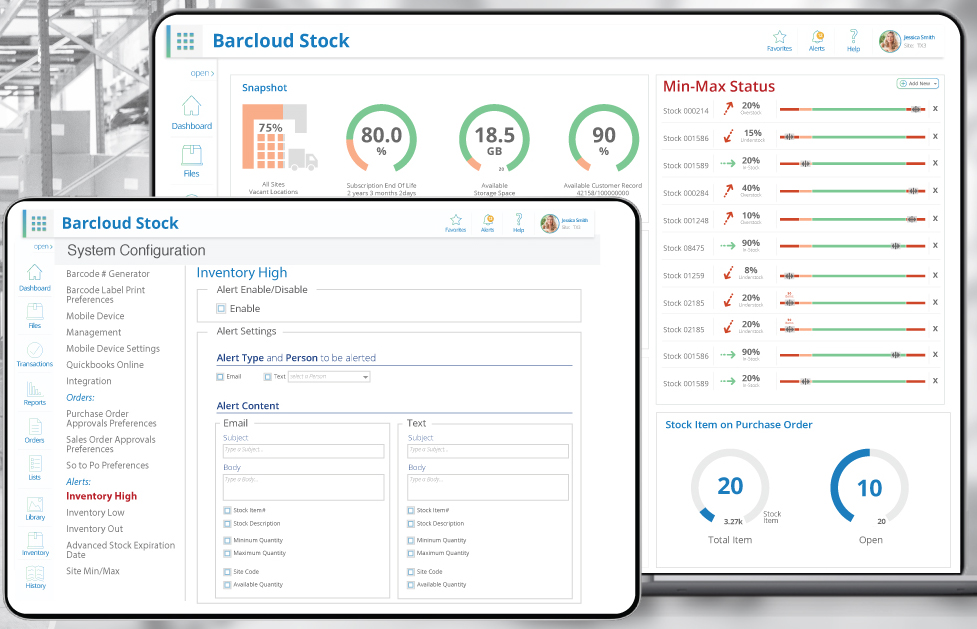

Set optimal Inventory Min/Max quantity levels to improve inventory turnover, eliminate outages, and make That's where our Inventory Min/Max Status Scale Panel comes in handy for all system users. Watch this video to learn more about how the Min/Max Inventory Quantity Status works.

...lack of quality min/max level settings of stock on order that was already in stock $1,1011, MIN MAX When the stock level drops below its "min" value on how to implement this initiative effectively by reading our blog titled: "Key considerations for setting optimal min/max inventory stock levels

allow such a dedicated software to act and replace the basic Min/Max method of the main software, the following rules can be used: When no reorder needs to be made (according to the dedicated inventory optimization software), the Min quantity will be set at zero or even -1, preventing any reorder from taking place. When a reorder of X-quantity needs to be made and …

Notes: In your max description you mention min three times. They also changed it so you had to figure out how not to break everything and paste their changes back into your source tree (or vice versa). And now I must figure out how to incorporate both.

When you min-max plan at the organization level, Oracle Inventory looks at inventory balances, purchase orders and WIP jobs as supply and sales order and WIP job component requirements as demand. To use min-max planning at the organization level you must set the item attributes used

01, 2009 · 1- For a given materialn,in general, minimum stock is 0, excepted materials with security stock Minimum Safety Stock in the Material master MRP2 View. 2- The same case for maximum stock, in general is unlimited, excepted materials with "maximum stock level" in material master MRP1 view.

acoustic

Is the determination if min/max inventory levels at all like determining the upper and lower control limits in statistics? Please need a good simple explanation and equation about calculating min/max inventory control levels? Many thanks.

To set this up go to Inventory > Item Master Data > Inventory Data. On this tab under Inventory Level uncheck the box by Manage Inventory by Warehouse and then you can enter How can you determine whether the system will block the transaction on the one hand, or issue an alert on the other?

Inventory - Setting Max/Min Levels - The Uniform Solution. Setting max and min stock levels will determine your desired stock level, and when the program automatically reorders … min max inventory policy.

Min/Max inventory remains a popular inventory management approach to capture opportunistic sales by carrying safety stock and amalgamates volumes to reduce pricing and incoming freight costs. To avoid stockouts, you should set the minimum and maximum levels quite

How. Details: Inventory Control Step 6: Set Min/Max Levels Setting up minimum and maximum ordering levels for your parts is going to provide you with the most headway in maintaining inventory control.

Inventory - Setting Max/Min Levels - The Uniform Solution. Maximum and Minimum stock levels for a particular style and color are set from the Inventory List in The Uniform Solution. Setting max and min stock levels will determine your desired stock level, and when the program

Nov 16, 2010 · Min-Max Inventory Management: Determining Min-Max Levels Contrary to popular belief, Min-Max is still a popular inventory management approach. It accounts for any unforeseen spikes in demand, allows companies to capture opportunistic sales by carrying …