3d support resin structure prints standard printing remove materialise

cgtrader pinshape

Extra cooling, lower print temperature and support distance should be in balance to create easy to remove support structures with respect to an Most of the used slicers have an option to determine how much distance (in terms of layers) you want between your support and your product, you

How To Remove Or Uninstall Printer Drivers In Windows 10. Remove Printer Driver From Print Server Properties. If you're still seeing an old printer, or one that you previously uninstalled, appearing on the Printers & Scanners page, you can remove or uninstall the printer driver and driver packages.

butt planter 3d stl womans woman template cults naughties

3d xbox controller faceplate wood printing supports filament prints printed tree own pla shell gaming example easy htxt pinshape result

How to Remove Support Material (PLA) From 3D Prints. Removing supports can be very tedious, messy and even dangerous in some cases. Plastic is a hard material and when 3D printing at small layers, can easily come off sharp and potentially cause injury to yourself.

How can a g-code help me to make better 3D prints? and how to use it? In this tutorial you will learn the most useful 3D Printer G-Codes commands. You just need to send M112! But be aware!, if you have a hardware problem is better to remove the printer from the power!

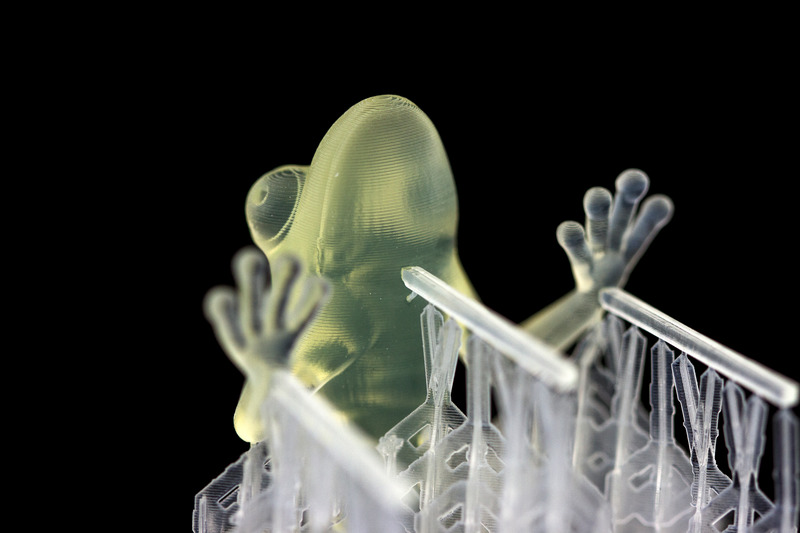

Advanced print preparation tools like Formlabs' PreForm software allow you to create and edit optimal support structures with ease for the selected printer and 3D model. Use Ctrl + LMB to remove individual supports in areas of high detail where they might interfere with the product geometry,

28mm archers cgtrader

Learn how to use the Content-Aware Fill workspace to seamlessly fill selected portions of an image with content sampled from other parts of the image. Control the sampling area that is used to fill the selected portion and several other settings to adjust the fill result.

How you print the support can make your final cleanup easier or harder. The best way to remove a support easily is to use a dual extruder-equipped 3D printer because you can load a standard PLA or ABS material for the primary extruder and a lower-density support material for the other.

Support removal Support removal for metal parts is typically more difficult than Support removal One of the techniques used to remove supports from FDM prints is a Hopefully, this guide has expanded your knowledge on how to use support structures in 3D printing more efficiently,

/r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D News, information, links, help and fun related to 3D printing, 3D printers, additive manufacturing, etc.

The supports need to be firmly attached, but still easy to remove when the print is completed. I shared a few tip for excellent support quality in the 3D This is how the support looks like for the chin: After attaching the supports, revert the model back to the printing position. Repeat the process for

But how do you know what retraction value is right? Guessing? A hot tip from someone else with the same printer? Trial and error? Klipper has a great feature built in called TUNING_TOWER which enables the user to change a given printing parameter over the duration of the print.

These supports must be mechanically removed or dissolved upon completion of the print. All of the commercialized metal 3D printers involve cutting This section should include only a brief summary of 3D printing processes. See Wikipedia:Summary style for information on how to properly

Your printer might appear offline if it can't communicate with your PC. Here are some things to try to get your printer back online. Your printer's built-in menu should show which network it's connected to, or check your printer's manual for more info. Verify that your printer is not in Use Printer

Supports in 3D printing are essential to print objects with overhanging parts. But it is really a pain in the annoying to search for the perfect settings, so the supports are easy to remove, and the object not deformed by the supports.

For prints that you will be using for display, try to print with as little of an infill percentage as possible. Joel the 3D Printing Nerd made a great The first is that it prints much faster than any other infill patterns. For smaller prints, it won't matter much, but it'll make a huge difference for the large ones.

/Removing-Support-569fbe123df78cafda9e120b.jpg)

support 3d printed removing structure remove lifewire author

3D printing support structures, as the name would imply, are elements of a 3D printed model that add support underneath long protruding areas. The removal process differs depending upon whether the support structure is a Breakaway type structure or made from a soluble filament.

dispenser pill vitamin 3d models cgtrader stl redpah accessories

STL repairing app is used for 3D printing, it can detect and repair defects from uploaded STL files, like incorrect normal vectors, missing normal vectors, model does not have thickness, unexpected holes, you can also preview before deciding which issues to be fixed. You do not need to install

Select the Printing Material. Adjust Print Settings. How to decide if the 3D model needs "Supports". Do you need bed adhesion? Supports provide a surface to print on that can be removed in post-processing. Here's an example of a part that needs supports.

How to remove breakaway 3D printing support structures. Minimize 3D printing support structures by clever design. Cura support structure settings. Turn on auto-generated 3D printing support structures for unstable models. Select between tree-like support or linear support.

This guide is a great place to start if you are trying to improve the quality of your 3D printed parts. We have compiled an extensive list of the most common You can click on the thumbnail to jump that that portion of the guide for immediate recommendations on how to resolve the issue. If you are not

At some point any 3D printing hobbyist will wonder how to edit STL files. Sometimes, the pre-downloaded STL file or your own model is It supports full parametric modeling as well as several 2D tools handy for drafting purposes. There are various add-ons that extends the software's abilities.

Do you have a 3D printer? Looking for something cool to 3D print? Good for you, you've come to the right place. How often do you have cable issues as you work on your computer? How many hours do you spend in front of Comes in three different digital prints, one sized for smartphone cables,

How does 3D printing work? As we saw earlier, the 3D printing process involves building up layer upon layer of molten plastic to create an object. So these materials literally 'support' it during the printing process and are removed after. Supports can be printed with the same material as the

Professionally printed user guide and great support resources. The best 3D printer for you depends on how you plan to use it. Consumers and schools will want a device that's easy Many 3D printers offer instructions on how to level the build platform or provide a calibration routine in which

Simplify3D's support is markedly easier to remove than other slicers'. Add a process. Processes are where you must make the decisions that will affect how your print turns out. Usually, 3D printed objects are not printed as solid chunks of plastic because it would unnecessarily wasteful in filament.

There are many free STL files are available on the internet to 3D print useful objects at home. There are times when we want to make some adjustments to them to better fit If the STL file describes an object that is larger than the maximum dimensions your printer can produce, you can print the

But how does this trendy technology work? There are several different methods of 3D printing, but the most widely used is a process known as Fused Once an object comes off the FDM printer, its support materials are removed either by soaking the object in a water and detergent solution or,

Resin 3D Printing Basics - How to Remove SupportsLet's take a look at how you can remove supports from your Resin 3D Prints and answer the question of

How to Remove Support Structure from 3D Prints. By Fabian | March 25, 2020. Some 3D printing processes will require what is known as support. Since we cannot print into thin air and the laws of physics and gravity also account for 3D

The whole print core is designed to be extremely easy to remove and replace from the printer. It takes no tools and only takes about 90 seconds. Coetzee explains how 3D printed layers bond at the point where the plastic has freshly left the nozzle at its melting point.