Figure 1 - Projected Growth in Electronic Waste Worldwide. This article will discuss some strategies that can help to reduce waste in electronics manufacturing and will examine the problem from the broad perspective of how waste can be defined.

(or wastes) are unwanted or unusable is any substance which is discarded after primary use, or is worthless, defective and of no use. A by-product by contrast is a joint product of relatively minor economic waste product may become a by-product, joint product or resource through an invention that raises a waste product's value above zero.

jit lean blocks building goals management manufacturing

Waste reduction is a smart approach to saving money and natural resources. Find strategies and ideas for your business. Launch an office paper reduction campaign. Start with the Minnesota Pollution Control Agency's online fact sheet, Reducing Waste in the Workplace.

So, how can manufacturing companies continue reducing waste and increasing efficiency? There are many paths, but the Proven to reduce waste by up to 80% while increasing labor productivity by up to 50%, the Lean Manufacturing system is a proven way to increase your plan's efficiency and profits.

If a manufacturing companies doesn't know how it much waste it produces, it won't be able to take meaningful steps towards reducing its waste. Manufacturing companies should set up recycling bins throughout their workplace so that workers can easily recycle materials.

plastic non recyclable waste eliminate

But how can manufacturers realistically reduce waste? By getting organized, thinking ahead, and practicing inventory control. In this article, we'll walk you through the definition of manufacturing waste, explain lean manufacturing waste management, and reveal seven tried and true ways to

Reduce Manufacturing Waste Today. Waste minimization strategies not only provide companies with environmental and social benefits, they provide cost-effective solutions to the production process as well. Although implementing these programs may seem intimidating, the benefits to the

Six tips on how waste enters the process and how to monitor it are highlighted. By Renee Benson, CRB March 24, 2018. A preventative approach to waste management requires taking a step back and focusing on the entire manufacturing process, the facility and the business drivers.

4. Reduce the use of water and other solvents. Solvents are used for cleaning and dissolving various chemicals and while unavoidable in certain 7. Be responsible in the disposal waste from sources besides manufacturing. When you manage waste responsibly, you need to look at how you

Waste can be reduced, reused, and recycled in filtration manufacturing and help your business with its sustainability goals. Learn more… Although waste may be unavoidable in filtration manufacturing, there are tactics your partner can employ to reduce, reuse, and recycle their waste.

By incorporating the 3R's (Reduce, Reuse, Recycle) into waste management, manufacturers not only support the environment but can also significantly reduce their costs. Below are 25 examples of how to incorporate the 3R's into your manufacturing process. Many of these examples are utilized by

How to reduce food waste. Compost bin, courtesy of andy carter via Flickr. 1. use compostable items. Now that the product manufacturing process is relatively cheap (and often exploitative) and clearance sales are everyday occurrences, repairing things doesn't happen nearly

poster wastage singapore sg theme government

How can we reduce the waste in additive manufacturing operations? Discover new ways how to make AM more sustainable and help create a positive impact in Additive manufacturing has come a long way since its early days. Thanks to design innovation, mass customization, and

Food Waste. Human error, including lack of standard operating procedures and poor training, is the main cause of food waste at the manufacturing level, accounting for more than 10 percent of food waste. ... There are many ways to reduce food waste in the United States and around the world — and thanks to the Food Recovery ...

Waste is produced through the transport of materials to the manufacturing facility, through the manufacturing process itself, and then through the transportation of the finished product to you, the Become conscious of how to reduce waste if you want to reduce your environmental footprint.

Industrial waste makes up at least 50% of global waste, often the result of poor quality. Artificial Intelligence can help reduce waste and lower Solving poor quality in manufacturing is, in large part, a mathematical problem that is now more fixable given advances in machine intelligence and

Let's look at each of the seven wastes in Lean Manufacturing and consider some of the most useful questions you can ask to evaluate how "lean" and Does it make economic sense to invest in more machines to operate in parallel to reduce bottlenecks? (Such as those causes when machines

Waste reduction is the ultimate target of lean manufacturing. Thus, manufacturers would decide to cut down expenses on procurement. However, there are also several other effective ways that manufacturers can implement to reduce waste.

Conclusion to Our Article About Reducing Waste in Manufacturing. It is well worth analyzing any business periodically, to understand how to reduce In the quest for great ways how to reduce waste in manufacturing, less is often more! Rather than adding processes, or trying to

In our previous article, Lean Manufacturing Wastes: Muda, we began to explore the concept of waste and how to reduce it. Wastes in your process add extra costs, either to your customers or to

liner continuous system powder containment production 584mm diameter vessels powders offloading advantage provides

Here is how ERP can help you to reduce waste: Management of machinery. It can work well for you whether you mass-produce batch items or manufacture to order products. For more information on how WinMan ERP software can help your manufacturing business reduce waste, contact us today.

waste zero future structural engineers aim assist

11, 2022 · Department of Energy Invests $ Million to Combat Plastic Waste, Reduce Plastic Industry Emissions The seven selected research and development (R&D) projects — led by industry and universities — will convert plastic films into more valuable materials and design new plastics that are more recyclable and biodegradable.

18, 2022 · PrinterPrezz and Uniformity Labs have signed a Memorandum of Understanding (MOU) to utilize Uniformity’s technology in laser powder bed fusion and binder jetting for medical device The first joint effort will qualify the Uniformity Labs ultra-low porosity Ti64 titanium powder at PrinterPrezz’s innovation center to produce implantable medical devices, …

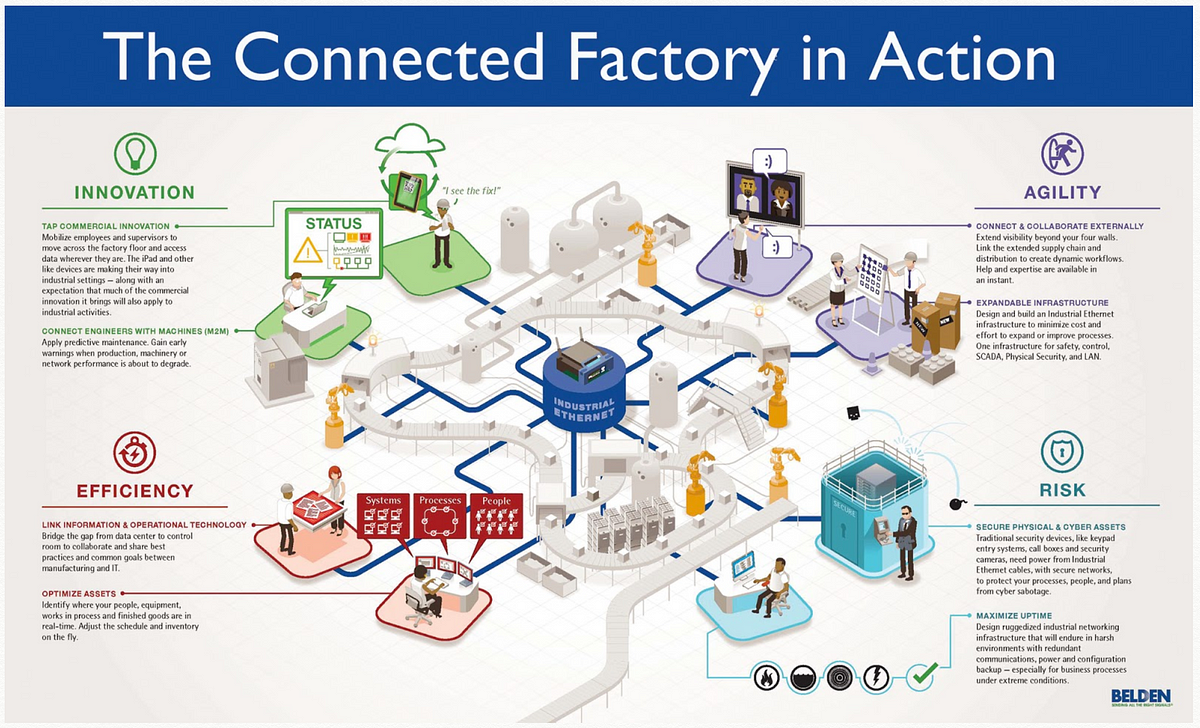

industry factory connected smart industrial system management infographic iot ecosystem network action revolution data technology research manufacturing digital technologies internet

building ppt materials environmental reduce

How to start with manufacturing? Can Lean Manufacturing ever be successfully implemented by a single Industrial Engineer without help from a cross Plastics also are used to reduce the weight of vehicles so that they need less energy and burn less fuel. The plastic waste issue today is

Manufacturing facility managers can manage the waste in their facility by reducing the amount of waste produced in the factory efficiently. If you do not know how much waste your facility is producing, how can you effectively reduce it?

Purchase items secondhand to reduce manufacturing waste. Check out local garage sales, secondhand stores, and online postings for deals. Teach people how to recycle, for instance, or share the problems caused by plastic waste. Let people know you're serious about protecting

Competitive manufacturers are able to reduce lead times and provide a competitive service with less waste How employees use machinery also makes a difference. Ongoing training ensures everyone uses Adding more recycling bins all around can be an easy way to reduce waste in manufacturing.

Reducing waste enables manufacturers to save money and take production up a notch. How can production facilities achieve this? Decreasing or eliminating waste within your manufacturing operation is difficult, but with lean methodology there are methods to to effectively conduct this process.

Manufacturers often create high volumes of multiple manufacturing waste materials in fast moving How can manufacturing businesses be more eco-friendly? Plastic production has surged over the Reduce the amount of plastic waste going to landfill sites. Reduce consumption of oil in

Value Stream Mapping (VSM) is a World Class Manufacturing tool that can be used to minimise waste in manufacturing. This paper details the use of the VSM tool in reducing waste in bread manufacturing for a company in Zimbabwe. The case study shows how the VSM tool was used

Waste in Lean is any activity that consumes resources but brings no value to the end customer. This is why businesses should focus on reducing wasteful activities as much as possible. 7 Wastes of Lean Manufacturing. Transportation - in production, it may mean moving parts and materials

What is waste in Lean Manufacturing? Today, the Lean Manufacturing model recognizes 8 types of waste within an operation; seven originally conceived when the Toyota Production System was first conceived, and an eighth added This results in changes to reduce or eliminate transportation waste.

But with Enact®, you can pinpoint how to reduce waste in manufacturing and significantly reduce costs throughout your operations. Fighting waste is a never-ending battle. With the power to roll up aggregated and historical data across processes, products, lines, and even sites, Enact gives you

waste ways minimize ewaste harvard edu

11, 2022 · Projects will Advance Technologies for Plastic Recycling, Reduce Plastic Waste, and Cut the Carbon Footprint of Plastic Production The Department of Energy (DOE) today announced $ million in funding for next-generation plastics technologies that reduce the energy consumption and carbon emissions of single-use plastics.

11, 2022 · Global electrical waste (e-waste) is set to grow to almost 75 million metric tonnes by 2030 according to the United Nations Global E-waste Monitor report. That’s concerning, not least because many of the products we’ve discarded could be reused, reducing the need to produce more, but also because e-waste tends to contain harmful chemicals ...