How To Optimize CNC Plasma Cutting Process? Plasma Cutter Not Arcing ( Proved 7 Troubleshooting Methods). hello, good day., im ATTA RAHMAN, from nigeria. please i'm having troubles operating it. its a CNC 10 series plasma displays the following

I like SheetCam for generating G-code for a CNC plasma cutter from DXF or SVG drawings, but I prefer free and/or open source programs that students can use on their own computers. Inkscape and the Gcodetools plug-in achieve that.

A detailed tutorial about how to use Inkscape to design for a CNC Plasma Table. All the 2D graphic design programs have a learning curve but a lot of the tools are similar between programs they just have different names. Inkscape For Plasma Cutter Design Daryl Kehler.

plasma cut numbers 3d steel industrial handmade

dxf cnc plasma cut ready bundle machine machines cutting packages entire table milling tables visit dxfforcnc router ring laser ball

Introduction 8. CNC Plasma Cutting 101 9. Quick Machine Parameters Setup 12. Hard stop installation for Hard Stop Homing 12. Creating a G-Code File from a DXF drawing 68. How it works 69. Saving and Saving Special 69. Scale the object with this ratio xxx to 1 70.

We don't recommend people build their own plasma cutter due to the risks involved when playing with high voltage electricity, dangerous flames and gases. We also understand that buying a brand new plasma cutter can be quite expensive. That's why people feel the need to build their own

CNC Plasma cutting is a complex operation and it is recommended that integrators choose a suitable plasma machine. There is a lot of confusion around how to decode the THCAD output so lets consider the Mesa 7i76e and the THCAD-10 for a moment with the following hypothetical

This basic guide will take you through what CNC plasma cutting is and how it works. If you're thinking of getting into the world of CNC plasma cutting, there are a few things you need to consider first.

Relatively speaking, the next most affordable step up is a CNC plasma cutter. All in all the project cost approximately $8,000, though after lessons learned, they think they could redo it for around $6,000. When they first started testing it, they were dismayed with how dirty the room got from the fine

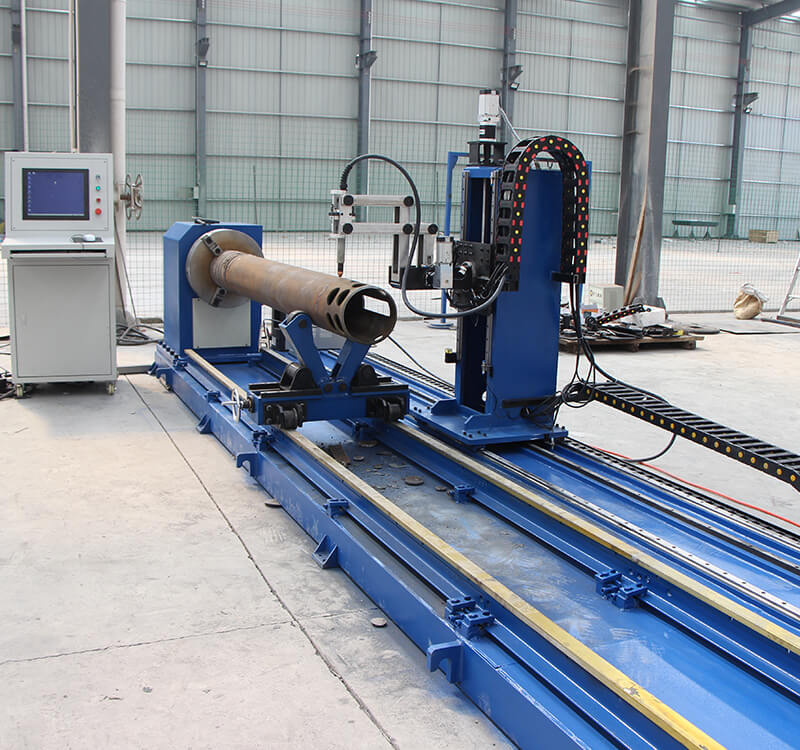

CNC Gas Oxyfuel Flame Plasma Cutting Table from Newlin Machinery is an excellent option for people trying to find the best CNC plasma cutting table. You will find a flashcard with demo video about how to set up the plasma table. It has a modern CNC control centre with compact

CNC Plasma Cutter. Purpose of the machine. Many fabricators use plasma arc cutting torches every day, either to replace or complement saws How the machine works. Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma.

How To Make Templates For Plasma Cutter Metal Art. Plasma cutter and design template. If you are one of the lucky few who own a CNC Plasma cutter. There are many free and paid templates available to download online. This won't only ensure a smooth cut but also save you time

Cutting an NC file with the CNC Plasma Cutter 1 Check torch consumables and air pressure 2 Launch the Techno CNC Interface. This lesson contains a explanation of how the system automatically controls torch height. Review and discuss this concept.

Plasma cutters are nice because they can make many different things, from signs to motor mounts inside combat robots. For your part file, make sure it is compatible with your plasma cutter. For PlasmaCAM, I usually use a .dxf file. To get this, I take a 3D part file, make a projection from the top

This plasma cutter is controlled using the Mach3 software package, familiar to many home-CNC builders including myself. He's even been able to use it with both a PlayStation 3 and Xbox 360 controller, which simply required finding the appropriate software plugins for the controllers.

Plasma Cutter + CNC Table + Auto Load/Unload = Tool to build other projects faster. With the table capable to cut across the width of the material (48 inches), a program was created to act as the final cut to remove Nice Build! Seeing this project reminds me of the CNC plasma cutter that I started on.

Learn about CNC Programming including CNC machining, g-code and CAM/CAD. CNC programmers write instructions for CNC machines, where a computer is connected to the mill Learn how to generate 2D toolpaths for your parts, from roughing to finishing, and then generating G-code.

ARTCAM Software for Plasma Cutting Machine How to make the file by ARTCAM for plasma cutting? Video Description: Building a CNC plasma cutter at home is as awesome as it sounds, albeit a little dangerous.

Competing CNC plasma cutting table manufacturers use a combination of different suppliers to build a pieced-together machine. This leaves their customers looking for help among a myriad of companies. Lincoln Electric knows how complicated CNC plasma cutting technology is and how hard it can

How to Operate a Plasma Cutter? A plasma cutters tables for sale is capable of cutting thick metal sheets in any shape and size. This computer-controlled machine gives instructions through a computer over the manual handheld plasma cutter. It is compatible with optional CNC parts

CNC Plasma cutter. Team members. Jimi Lehtola. Goal of this project is to have working CNC Plasma cutter that can cut metals at least up to 10 mm thickness. The machine should be built to last in own personal use and it should be able to cut parts that have dimensions of 350 x 850 mm.

How to convert your OX CNC to a plasma cutter at low cost. CNC Plasma cutter: 608ZZ on steel square tube linear rollers Welded frame HDT2-15 Belt Drive Tradeweld Cut-40 Plasma cutter with converted hand torch Virtual Torch Improvements to a cnc plasma cutter i designed a while back.

CNC Plasma Cutter Tool Training. Gui Cavalcanti 4/29/2013. 1. Introduction to CNC gantries and safety 2. Introduction to plasma cutters and safety 3. Overview of routine plasma cutter maintenance 4. Discussion of sheet metal safety 5. Overview of CNC plasma cutting 6. Mechanical design

plasma cnc controller australia

dxf plasma deer cnc gizmoplans animals whitetail cutting realistic plans sign sell pob jelen

Learn how to use computer controlled motion to automatically and precisely move around the Project Overview. I had always thought that a CNC plasma table would either be too dangerous or I just load in a .DXF file into my favorite CAM program, generate some G-code, and the plasma

A plasma cutting torch is a commonly used tool for cutting metals for a wide variety of purposes. The CNC reads the part program and then outputs signals to the machine's drive system which But the basics of a CNC plasma cutter described above will be common to all such machines, from

eagle dxf cnc head plasma

For plasma cutting systems and some routing systems, you would use open, single-line cut paths. I am looking for a way to process off -cuts and remnant plate on a CNC plasma cutter. These off cuts can be of various sizes and shapes which remain even after nesting of large parts from Bigger plates.

plasma greencut table cnc water cutting fluid arc coolant introducing performance corrosion does image2

Know-how - Plasma cutting system. CNC plasma cutting systems convince with economical and precise cuts and are unrivalled, especially for medium material In principle, all conductive materials can be processed with a CNC plasma cutting machine. In practice, CNC plasma cutters are used

The term CNC refers to Computer Numerical Control which means that a computer is used to direct the machines motion based on numerical codes in a program. A CNC plasma cutter is necessary to achieve accurate and edge quality cuts for most metal fabrication projects.

This video shows you how to run an automated plasma cutter. The cut is taken from a drawing done in AutoCAD that was saved as a dxf file. Thanks

cnc lincoln torchmate plasma machine cutting

How Does A CNC Plasma Cutter Work? Plasma cutting is a machining method that uses the heat of a high-temperature plasma arc to melt at a metal workpiece, and to eliminate the molten metal by high-speed plasma momentum to How To Choose A Dust Collector for CNC Plasma Cutting Table?

are new to CNC programming. HSMWorks also stores all data in the SolidWorks Part or Assembly file which makes file management simpler. If the learner already knows how to use SolidWorks they already know most of what they need to use HSMWorks. All of these attributes are essential for

welding welder plasma tig cut cnc metal grinder cutting dxf clip fabrication cutter signs decals svg silhouette table laser key

bevelling beveling accuracy concise advantages intuitive automatic