This article covers how to identify the major causes of fulfillment errors in your warehouse operation, and practices which will decrease or eliminate them. Additionally, look at how voice technology can be used not only in picking, but anywhere data entry happens in warehousing processes.

igz sap warehousing

warehouse management team accountability

The picking and packing of ecommerce orders can be repetitive, mistake-prone work. This article will explain how to design a picking and packing process to reduce errors. By placing barcodes on storage locations, a warehouse employee must first get to that location before he or she

How to solve it. Quite simply: eliminate paper from your warehouse by using warehouse management software with a mobile app. The mobile app replaces the paper, a bit like your mobile phone replaced the handwritten letter. When you remove the room for human error, you're in a good position

How do you reduce pick errors in the warehouse? Shipping inaccurate orders can frustrate customers awaiting mission-critical supplies. Reducing picking errors is essential to maintaining customer satisfaction. Keeping an accurate warehouse inventory and shipping accurate orders are key

skuvault

As a warehouse manager yourself, experiencing the consumer side of a picking error should help you understand the importance of intercepting and preventing those errors in the warehouse. Picking errors diminish customer satisfaction—just think back to how you felt when you received the

How accurate is your warehouse's picking operation? In an ideal world, every order that gets picked and sent out to a customer would be perfect. Pick errors can happen for any number of reasons. Understanding some of the more common picking errors can allow you to prevent them

Although warehouse management systems are able to generate and print labels for locations, we recommend design labels using a third party software. There are several methods to define an optimal route in a warehouse, but not all of them work in real life, which is why we recommend

As a warehouse manager, it's up to you to keep inventory and picking errors to a bare minimum. Here are five ways you can prevent inventory errors and keep your accuracy rates up. If your warehouse is a bit behind the times as far as technology goes, going digital could pay off in a big way.

Order picking errors are time consuming and costly. Read our guide on how to reduce warehouse picking error rates in your facility. Invest in a warehouse management system that works for your team. Warehouse automation technology is necessary to stay competitive in today's industry and

WHM X3 prevents picking errors by alerting the user to any incorrect items scanned and with automated system checks ensuring that only correct products

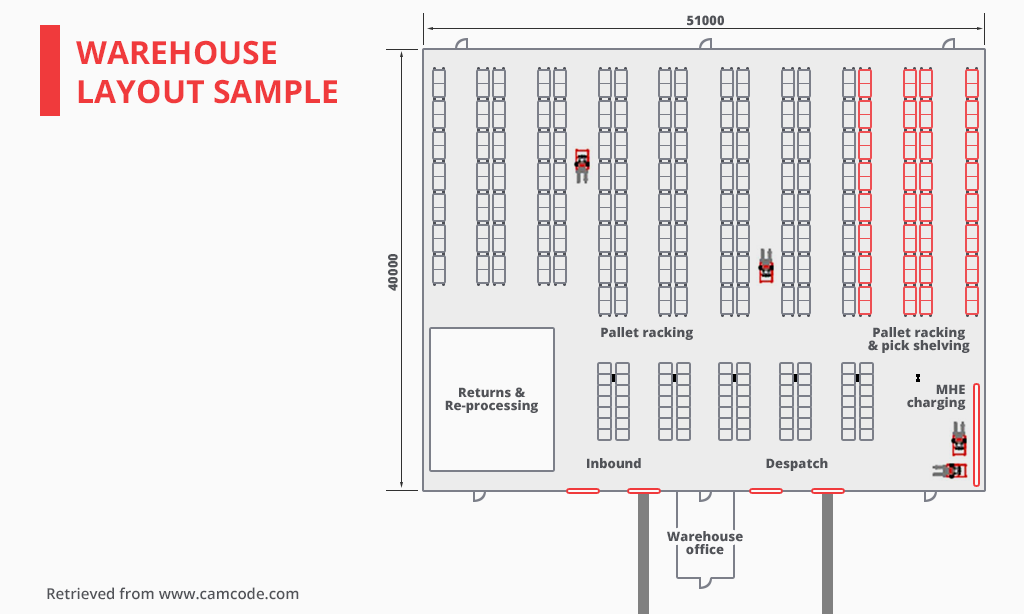

Meet Our Panel of Warehouse Inventory Management Experts A warehouse should be laid out in a manner that reduces time spent bending over, picking up, walking from one station to another, etc. Scan both the product and the location on put-away to prevent errors. Only store one product

Warehouse picking errors impact customer satisfaction and ultimately, your revenues and profit margins. To prevent this, you should leverage the best practices outlined above and adopt the right technology. Click here to learn more about how collaborative robots can help reduce picking

Picking errors in manufacturing warehouses can slow-down production lines, while inefficient order picking in DCs weighs down profits. If you currently operate a warehouse or distribution center fulfilling orders and deal with speed, accuracy, organization and labor issues there are many

While fulfillment errors can be costly, the most severe impact is losing a customer for life. Here are seven major sources of errors and how to reduce them. Also look at how voice technology can be used not only in picking but anywhere data entry happens in your warehousing processes.

Measuring picking errors and where and how they occur is in everyone's interests, and it is important to get this point across to your workforce, so that you have their support. One method for reducing errors is to bring in a checking system, so all picked stock goes through a second checking process.

All warehouses go through this issue, and how you deal with the problem and the employees will go a long way in solving the problem. Together with necessary labeling on respective goods, RF scanner will be the first gate to prevent picking error. The picker who validates goods when picking-up

lin kedto how warehouse operators perceive the usefulness of modern technology, the. introduction of modern work processes and their own accountability in the management of work proces ses in a company's warehouse t aking into account the spe cifics. involved in preventing warehousing errors.

Warehouse picking error rates are more than a percentage of hits against misses. They come with a real-world cost. Understanding the cost of each Before you start tackling your warehouse picking error rates, it's important to know the cost of your losses. Pick rate accuracy helps streamline

Pick-to-Light and Put-to-Light Systems: These systems use mobile barcode scanning devices synced to digital light displays to direct warehouse pickers where This ecosystem will help you eliminate human error, capture critical warehouse performance and inventory data, and store it in a centralized

5 ways to reduce warehouse picking errors. Leverage the right technology. Review storage strategies regularly. Make sure all items are properly identified and labeled. Conduct regular inventory checks. Assign IDs to associates to identify problems and track errors. How can I get faster at picking orders?

Smart trolley application reduce picking error in warehouse, superstores and shopping centres. Table: How Smart Trolley Works in Warehouse to Reduce Picking Errors Types of Error How Smart Trolley Works to Reduce Error Miss Pick In a case where a

If your errors are down to warehouse staff put away/picking errors, this comes down to how you can get more out of your staff. I'm not a fan of league tables when there is no fincanial benifit to How to Write an Effective Problem Statement. High-performance Teams: Understanding Team Cohesiveness.

sendcloud

How to Prevent Picking and Shipping Errors. Shipping errors will occur in every business, regardless of size. 8. Implement an automated warehouse system. There are several technologies you can use to automate your warehouse including robotics, RFID tagging, cloud computing and

To optimize the picking process, warehouse managers looking to improve warehouse operations and reduce costs should use these best practices. When optimizing the picking process in a warehouse, it is important to recognize two key concepts. First, no one strategy or technology fits

Warehouse picking is a key part of the fulfillment process. Learn strategies and systems to keep costs low, improve efficiency, and more. Investing in a warehouse order picking system that can group similar orders with nearby inventory to a single picker will make the order picking process

Do you know how accurate your warehouse picking operation is? In an ideal warehouse world, every order that Picking errors can occur for many reasons but, it is important you fully understand some of the more common picking errors to help you prevent them from happening in your warehouse.

Prevent human error by identifying its potential. Potential is a funny thing. It can be a sign of future success or a warning about future errors. While vehicles are in use, telematics can monitor speed limits and control access to specific areas of the warehouse — for example, refusing entrance

racking warehousing innovecs warehouses improving

One effective way to prevent warehouse tracking errors is to reduce the size of your inventory in terms of the number of individual products you Planning Picking Paths Poorly. If you're wondering how to reduce warehouse errors and where you can start, you can begin by analyzing the

For picking, what systems can you implement to boost accuracy and stop picking errors? Consider voice control that guides workers on where to go and what to pick or improved instructions to prevent the pickers to get 10 pieces instead of 10 boxes. Or RFID tags that enable you to track each item'

barcode scanning picking label ewm scan receiving

automate sendcloud process

Picking errors are the silent assassin of warehouses: no-one sees or hears them at the time, but they're going to kill your warehouse's productivity regardless. It's all too tempting with pick errors to put them down to human error and move on. You may be handling thousands of orders a day,