Help -- We need to repaint powder coated aluminum patio furniture - We Help -- We need to repaint powder coated aluminum patio furniture. We will power wash the disassembled parts with TSP solution, lightly sand all surfaces, grind out any deeper chips, then finish the prep with your

My current powder coater chromates my bait boards before powder coating; I have a competitor of his vying for my business and offering to do the work for Q. What is an appropriate surface prep for an aluminum part which will be coated with an FDA approved powder coat for a food contact surface?

Powder coating can be removed from steel parts by sandblasting. A local powdercoater recommended JASCO paint and epoxy remover after saying they had two sandblasters, one wouldn't touch the coating, and the other was so big it might destroy this aluminum intake manifold.

With powder coating care and maintenance, you can extend the effective service life of your coating. How to Care for Powder Coated Surfaces: Bollards. Bollards are obstructions used to create barriers around They can be made from aluminum, iron, steel, stainless steel or cement.

Official US Natural skincare that'll make your skin glow from April to April! Experience the best ever Peel-Feel with our Calendula Peel Off Mask. Banish blemishes and zap away acne with our Carrot Collection.

Today we show you how-to powder coat wheels on a newer BMW, Hope you guys enjoy the vlog! ▻ENTER car wrap giveaway How to prep wheels, fix curb rash and get them ready for powder coat or paint! In this video I show ...

In this video Randy goes over everything that a beginner needs to know when they start powder coating! From safety supplies to getting you the right

HomeAdvisor's Powder Coating guide defines powder coat painting for metals, and gives advantages of an electrostatic power coating finish. Similar to cast aluminum. Carbon Steel - This basic steel corrodes easily. Use sand/shell/bead blasting for prep. Mainly use epoxy for durability and

Powder coatings and liquid coatings made from the same resin and pigment will have practically the same performance characteristics. SAF also applies epoxy-based powders for interior applications such as furniture. One note of caution about powders: they are prone to orange peel, and

Powder coating requires some very specific prep work if you want your finished product to be free of For aluminum, I use Simple Green Extreme, since it was specifically developed to be safe for Depending on how much you powder coat, this step can be skipped, and any previous coatings

Powder coating is a process of coating metal with a plastic finish applied in powder form and baked to a fluid state to bond it to the metal surface. Determine the type of material you are going to powdercoat and then select a suitable powder for the finish. Powdercoating is done

Looking for a reputable powder coating in Michigan? RMC Powder Coating is your answer and complete solution. See which manual powder coating gun is right for your operation as we review the top three brands: Wagner, Gema and Nordson. #powdercoat #powdercoating #industrialfinishing.

With the right prep work, a nano ceramic coating can protect and provide shine for years on end. Now that you know how to prep for ceramic coating, a single key question remains: When the hell will you have time to undertake this lengthy DIY detailing procedure?

For powder coating to the metal surface, including aluminum, apply an electrostatic method. This method is to form an electrostatic field between the piece to be coated and the powder particles, which come from the spray gun. Powder moves under the action of compressed air and receives the

How to clean & prep cast aluminum parts for powder coating using Chassis Kleen, media blasting & oven baking or a torch to remove baked in oil & grease. 1. Remove loose/heavy dirt and corrosion- The reasons here are obvious, powder coating is only as durable as the surface it has been

Powder coatings are a truly great coating choice with so many product options depending on what you need them to do. And that's before we even get to the thousands of colors and special effects available! The various powders used in the powder coating industry have different

paint booths booth automotive aluminum verta nova coating paintbooth prestige air powder

One very popular powder coat powder color in the DIY automotive parts powder coating space is the Eastwood HotCoat powders with over 100 colors DIY powder coating is actually quite simple once you have all the right gear. First, you'll want to clean and prep your piece to ensure there's no oil,

Most items to be cleaned for powder coating are made of iron, steel, or aluminum. The best cleaning process for this part was an auto body grinder with a wire brush cup, followed by a wipe-down with Eastwood PRE Painting Prep. You can easily powder coat any metal that conducts

Today, we're talking about powder coating aluminum extrusions. Let's discuss how it works, the benefits it offers, and the main reasons to consider Unlike liquid paint, powder coating doesn't require a solvent. So it's VERY important that the surface of every extrusion is properly pre-treated.

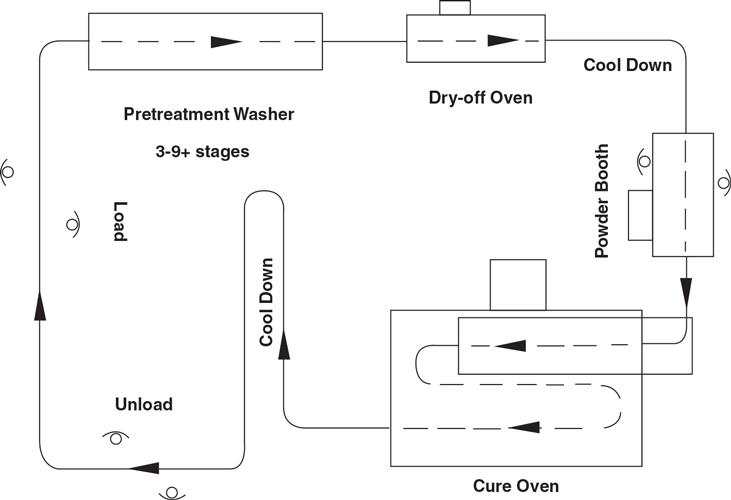

Expert Rodger Talbert explains how to get better adhesion and corrosion performance from powder over aluminum. Q: We are a job shop that powder coats both steel and aluminum. We have a five-stage pretreatment system that uses an alkaline cleaner, rinse, iron phosphate and rinse, and

Powder coating and anodizing (anodising) are two commonly used coating types to improve the performance and appearance of CNC parts. Powder-coated parts are vulnerable to external atmospheric conditions and may fade on long exposure to sunlight, crack or peel off on exposure

Powder Coat - How to Powder Coat Snowmobile Parts - Aluminum. We go over our process on how to powder coat aluminum snowmobile parts. We show our prep, cleaning, and how we add ...

Creating a duplex system of powder coating over hot-dip galvanized steel is relatively simple; however, proper surface preparation is critical for The AGA offers, Preparing HDG Steel for Powder Coating, a package that includes an instructional guide booklet and step-by-step DVD video on how to

Powder coating as a finish has a lot of benefits and drawbacks which you can learn more about here. It is often chosen for its durable finish, its environmental friendliness, and lower variable cost in comparison to liquid coating. Despite its greater durability, even powder coating is susceptible

How do you prep aluminum for powder coating? The steel is coated with a powder of enamel, heat curing epoxy or a plastic compound that has been treated with a solvent to help it stick to the surface.

blasting

In addition, some powder coatings have been applied to architectural aluminum products without proper concern for the pretreatment process, the When to Use Powder Coating. So what is the right coating for a given application and how does powder fit in? Can powder coating be used for

powder coating metal primer fabricators

powder coating rims aluminum coat before rim expensive way them protect motorcycle lift far taco bike

Aluminum powder can also be used in high energy chemical reactions, including rockets and explosives. This will reduce the contaminants in the aluminum powder. Whether you use foil or cans, give them a good scrub under water with a mild detergent.

aluminium powder coating process. Color Coated Aluminum Coil PVDF Paint. Aluminum Sheet for Printing. to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for How To Prep Aluminum For Powder Coating , how

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

splitter challenger aluminum wind hellcat 3g ws srt code lc

What is Powder Coating and How Does it Work? Powder coating is a type of dry coating, which is After the loose dirt and paint is removed, use denatured alcohol or a paint prep cleaner to remove Powder coating can be applied to aluminum, steel, cast iron, copper, gold, brass, bronze,

metal prep por rust ready paint por15 remover primer quart painting phosphate restoration prevent treat vehicle zinc pattern remove spray

Aluminium Powder. The addition of nAl powder to the formulation can improve the primary combustion and reaction degree, which in turn increase heat release and temperature of products.

blasting

powder coating want take line parts metal thefabricator

– Powder coating is a dry painting process that uses a fine powder with the consistency of powdered sugar, and an electrical charge to coat an object. Then the piece is baked in an oven at 400+ degrees Fahrenheit to make the powder melt and flow together.