Injection moulding ( spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses,

Parts of Injection Molding machine: Injection molding process step by step Injection Moulding is a modern technique in which the grain is made up of the desired material like PVC, Plastics, etc. Flash. You can check this article from In-touch quality to know how to prevent these types of defects.

An injection moulding machine is a complex piece of machinery that creates one solid part by injecting molten materials through a reciprocating screw system into a mould. This machine is made of many components; it is primarily consisted of a hopper, a barrel containing a reciprocating

injection molding machine is one of the most important plastic processing can seperated into two types of machines, horizontal According to the different clamping unit structure of horizontal injection moulding machine, it can separated into traditional toggle link system

How to operate plastics injection machine #howtooperateplasticsinjectionmachine#dhonzkietv. Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould.

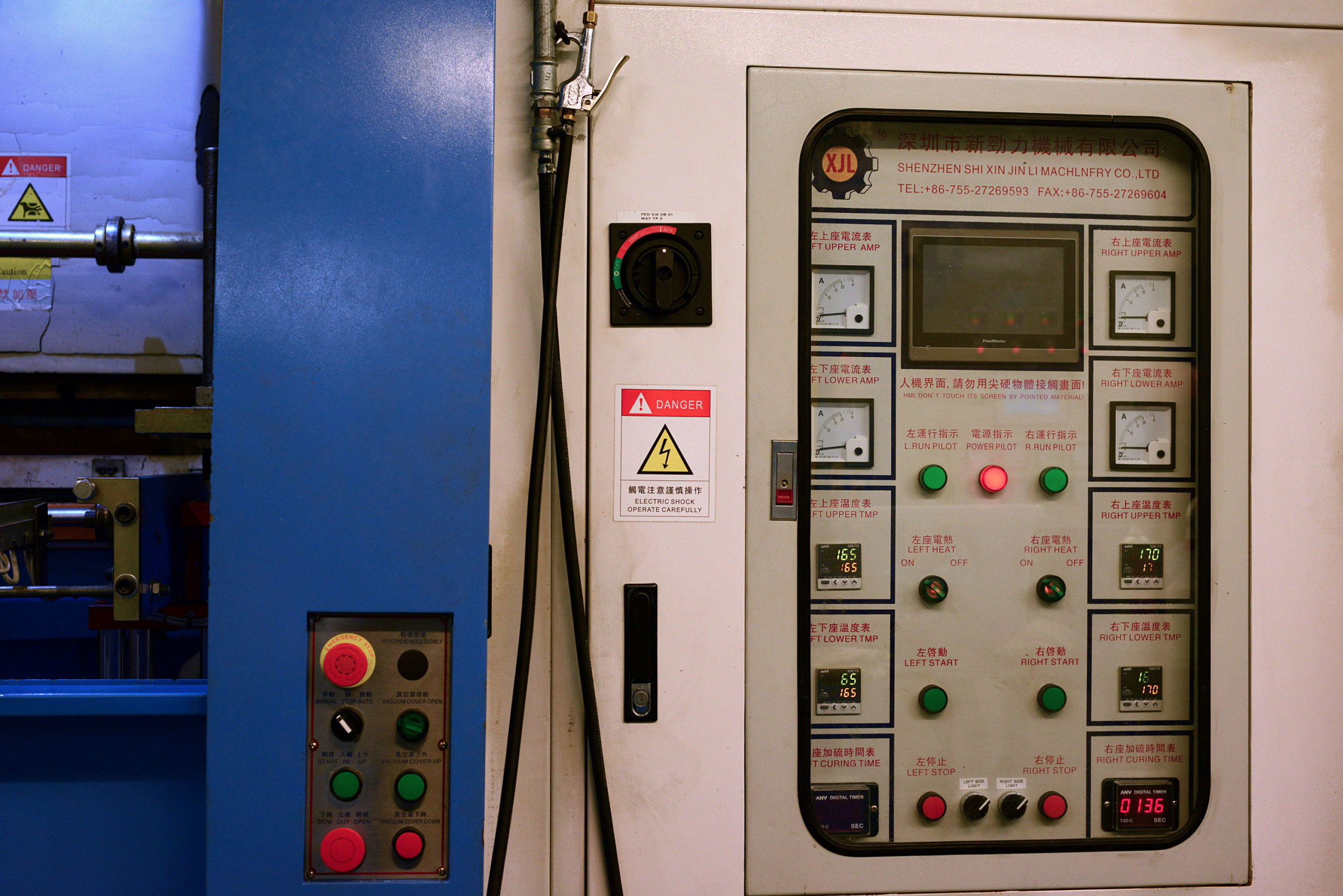

170t

δ: Stress IM: Injection Moulding P |L: Parting Line Re: Reynolds Number V: Velocity of Coolant : Density of Coolant µ: Absolute Viscosity : Kinematic : Screw Speed : Screw Radius A p: Projected Area P o: Operating Injection Pressure F C: Machine Clamp Force F C C:

plastic engel injection molding facility assembly molds ph

injection plunger

The comm ercial injection moulding machine can provide that knowledge at ease. however not all manufact uring labs have sufficient budget or space for it. Determination of initial process meters for injection molding is a highly skilled job and based on skilled operators know-how and intuitive

The first injection moulding machine was patented by an American inventor named John Wesly Hyatt. In comparison to the machines used today, this machine was quite simple. It worked like a giant hypodermic needle that used a plunger for injecting plastic, which passed through a heated

9. Injection Moulding Machine Process Melted material is injected into mould cavity and mold is held under pressure until the material cools and hardens. 29. Disadvantages Of Injection Moulding High initial tooling and machinery cost. Part design restrictions. Small runs of parts can

fastie ejector machine tie injection mold molding installation system quick example press situation imagination customize manufacturing unique smartflow usa

Injection Moulding design guidelines from the perspective of a design engineer. How to keep your manufacturer happy while also achieving the Injection moulding is a very common manufacturing technology for the mass-production of plastic parts. If you look at the plastic parts around you, it

Learn about DIY injection molding and all the tools necessary to utilize plastic injection molding in-house using 3D printed molds. While it is an ideal technique for large-scale production needs, traditional CNC machined metal molds have prohibitive high costs and long lead times for

Plastic injection molding is known as one of the most commonly used technologies for long production periods because it is very fast. But, how fast? Though its production speed may be dependent on the complexity of the mold structure, there is only about 15 to 30 seconds interval between cycle times.

Here are 11 common injection molding defects to watch out for when inspecting injection-molded products, what the causes are Pellets of material are melted and then injected at high pressure into a mold that will set to form the desired component. Here are 11 common injection molding defects

moulding compression vacuum machines knowledge

Injection Moulding Process. In the RIM process, a nylon block copolymer (NBC) which consists of alternating blocks of a nylon 6 polymer and an ether or ester Specific injection moulding processes have been developed for polymer materials available in the form of liquid reagents.

revolutionized illustrates

The injection-moulding process is best suited for producing articles made of thermoplastic The injection - moulding machine is shown in the process consists of feeding the compounded plastic The locking device has to be very skillfully designed in order to withstand high operating pressures.

Check Items Injection Molding Machine Performance Check Items Selects and measures 7 items most relevant to It indicates how severely the machine level is distorted, affecting wear of the mould directly. After Injection, check the screw position. ※ Operating mode (manual, semi-auto, auto)

Injection Molding - A Young Production Method Injection Molding - A Discontinuous Single-Stage Criteria to select mould for Injection Moulding Machine. Electric machines are considered the next generation injection molding machines, which eliminates the use of operating oil, resulting

Injection Molding is a manufacturing process for producing parts in large volume. It is most typically used in mass-production processes where the same part is being created thousands or even millions of times in succession. Why You Might Want to Use Injection Molding.

Learn how to use injection molding to mass produce plastic parts. Whether you're an experienced engineer or just getting started, this is your go-to guide for injection molding. Early injection molding machines used a barrel to heat up the plastic and a plunger to inject it to the mold.

Powerjet Special Plastic Injection Molding Machine with special designed Screw & Barrel For Learn the processes for how a plastic bearing is molding through an injection molded machine. Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould.

Geomiq's Injection Moulding design guide helps you with your design process to accelerate production time and reduce production costs. BASIC PRINCIPLES. Injection moulding is a formative manufacturing technology, material is formed from an amorphous shape into a fixed shape

Injection Molding Machine Introduction Technology: Polycarbonate injection molding is an engineering technology that involves transforming plastic into useful and original products. Important process conditions for polycarbonate injection molding are temperature, pressure and

Injection molding is a manufacturing process for the fabrication of plastic parts. Injection molding process, defect, equipment, and material information. Equipment. Injection molding machines have many components and are available in different configurations, including a horizontal

approximate

Injection Moulding Machine Instructions - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Injection moulding machine. 1. Turn power on to heaters and chiller [180°C for PP]. how to select plastic injection moulding machine.

blow extrusion molding liter machine machinery machines automatic

injection

Plastic Injection Moulding Machines with Auxiliary Equipment Safety During Maintenance and Production Interventions. The observed maintenance work involved injection moulding machine maintenance: mould polishing and mould cleaning.

How Does Plastic Injection Molding Work? Following are the basic steps of creating injection molded plastic Injection molding machines are a critical part of the entire molding process. This part of the injection moulding machine works for heating as well as injecting the resins inside the

: injection molding machine shoot the melt plastic into mould cavity,then cool the mould,let melt plastic become hard. become the products what we require. Now,how to operate a injection molding machine,you will have a idea,for more detail,you can leave your questions here.

Injection Molding Machine for wheel fabrication. 6. Process & machine schematics. Basic mould consisting of cavity and core plate. 31. Tooling for a plastic cup. Similar to an injection molding machine, but without a mold and continuous production.

The first injection moulding machines were based around pressure die casting technology used for metals processing, with patents registered in the USA in the 1870's specifically for celluloid processing. Further major industrial developments did not occur until the 1920's when a series of hand