Always wear safety goggles while operating the machine. And also never touch the drill bit or place your hands near the board while the spindle is active. There are two ways you could use this milling machine, either by using the offline 'fab' package, or the online website.

Milling machine is the backbone of the manufacturing industries. Almost it is capable of doing any milling operation whether it is gear milling, thread milling, angular milling It is a machine which is used to remove metals from the workpiece with the help of a revolving cutter called milling cutter.

milling machine operation vise basic accessories fig

A milling machine is one of the most influential and versatile kinds of machines found in the manufacturing industry. Hydraulic Clutch is a device used in automobiles that use hydraulic fluid to operate the clutch. Hydraulic clutch utilizes the fluid which is stored in a reservoir in place of the

Attempting Any Machining Operations. Vertical Milling Machine Operating Instructions. General Description. At first glance, a vertical mill looks similar to a drill press, but there are some important design differences; for • For accurate setups you should have and know how to use a dial indicator.

(grinding)A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (, via a hand crank), working animal (, horse mill), wind or water ().

One person can operate multiple automatic lathes for milling grooves of such hardware at the same time, which greatly saves labor, improves product [Technical Abstract] A dual-purpose machine tool for planing and milling of slab edge and beveling. It is composed of four parts: the seat body and

Like any other machine in the world, (CNC) machines must also be operated by specialists with knowledge of the product they want to produce the equipment needed for the product to be produced. Machinists work with (CNC)...

rodney milling attachment myford vertical lathes machine feed sized drive worm fine

machine arbors are made in various lengths and in standard diameters of 7/8,1,1 1/4, and 1 1/2 inch. The shank is made to fit the taper hole in the spindle while the other end is threaded. NOTE: The threaded end may have left or right-handed threads. The milling machine spindle may be self-holding or self-releasing.

hammer mill pellet machine wood line specification milling process abcmach

Milling Machine is important machine tool after Lathe Machine. Today we will read Definition, Parts, Types, Operations (With PDF) of Milling In today's article, you will learn about the definition, parts, types, and operation of a milling machine, also at the end of the article, I will add

Here you may to know how to operate a milling machine. Watch the video explanation about Manual Mill Tutorial Online, article, story, explanation, suggestion, youtube. Manual Mill Tutorial. Sharing buttons: Other suggestions

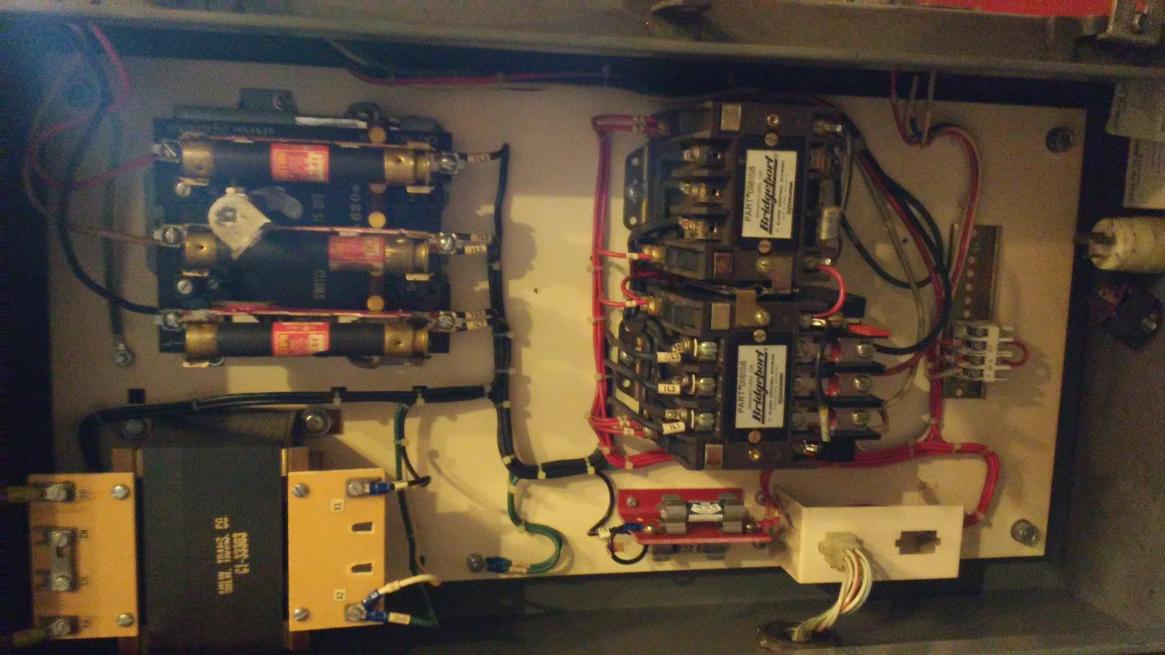

bridgeport mill wiring machine

solid commitment to help you meet your manufacturing goals and overcome challenges. We find the right machine for your job from milling, turning, multi-tasking, grinding, laser marking and 3D manufacturing equipment to Electrical Discharge Machining (EDM).

USA milling machines are setting new standards in both features and performance. Our full line of manual and CNC knee mills and CNC bed mills have been a favorite of job shops and production facilities for their dependability. In addition, our VMCs, universal mills and boring mills cater to workpieces that require more complex milling and production volume.

vertical milling machine is a precision tool used for shaping and fabrication by the removal of stock typically from metallic work pieces. Plastics and other materials can also be machined on the mill ... Shop Supervisor, Shop Monitors and those authorized by shop supervision to operate the tool. Tool Safety Rules

CNC Bed Mill. Instructions how to use a milling machine. Never operate a cutter backwards. Due to the clearance angle, the cutter will rub, producing a great deal of friction. Milling machine arbors are made in various lengths and in standard diameters of 7/8,1,1 1/4, and 1 1/2 inch.

what is Milling machine, it's working principle and Parts, Types, Operations, Milling Cutter, Advantages The knee houses the feed mechanism of the table and controls to operate it. Types of Milling Cutters. A milling machine is a machine tool that cuts metal as the workpiece is fed

Guideline To Operate A Milling Machine. First of all, look carefully into the machine, you will see a handle. That's the handle that you've to move. How to Machine a Part on a Mill/Drill Machine - Basic ... Crash Course in Milling: Chapter 1 - Basic Machine Anatomy ... How to Use a

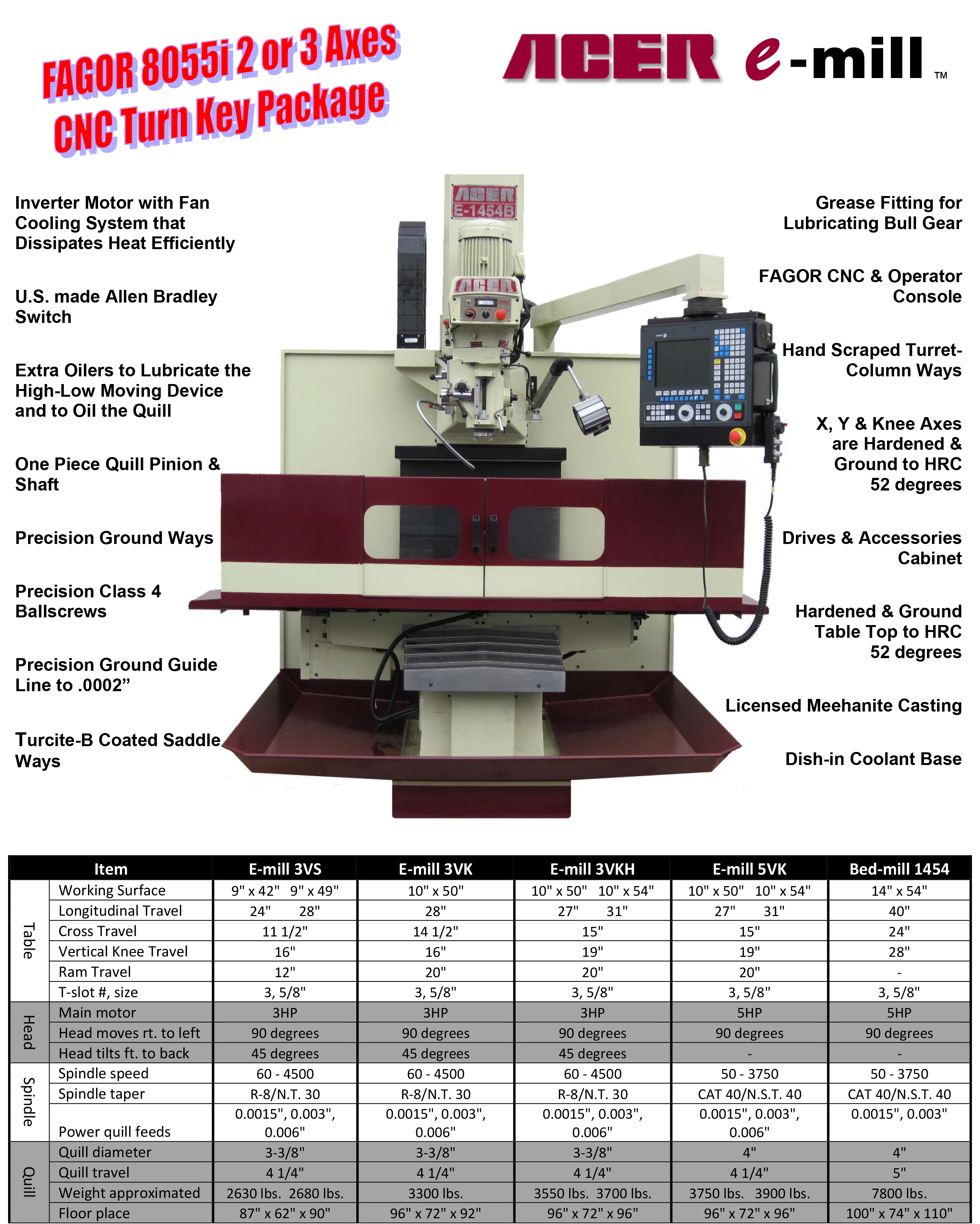

cnc machine milling vertical system control brand fagor acer axis machinery

machine can be equipped with a 15w laser head that can engrave most metal materials. and milling 2 in 1 to meet more needs. machine adopts the 775 spindle motor produced in Taiwan, which works efficiently and stably.

Operating a CNC milling machine takes quite a bit of knowledge and formal training. Information must be input into the machine's computer control for every aspect of the operation. You should set the machine to zero so that it can use the dimensions in the program to cut the raw material accurately.

A milling machine is basically used for shaping, routing, boring, and drilling metals and other solid materials. Generally there are two categories of the milling While most machinists still prefer manually operated and mechanically automated mills, there are also others who prefer CNC mills.

The first milling machines were based on the practice of rotary filing. CNC milling is a machining process that utilizes computerized controls to manage the movement and CNC, or Computer Numerical Control, places tools under the direct guidance of a computerized operating system.

Milling Machine is a machine tool that uses a multi-point cutting tool for removing a layer of material in the form of grooves from the This adjustment can be done manually or automatically by operating the elevating screw provided below the knee. How many types of Milling Machines are there?

Heavy CNC milling machine project started in 2015. A lot of different working steps are necessary to build a big CNC machine with good milling The water for cooling the milling tool has to be directed into the collection container with a filter to circle the water. Here is how the water drain was made

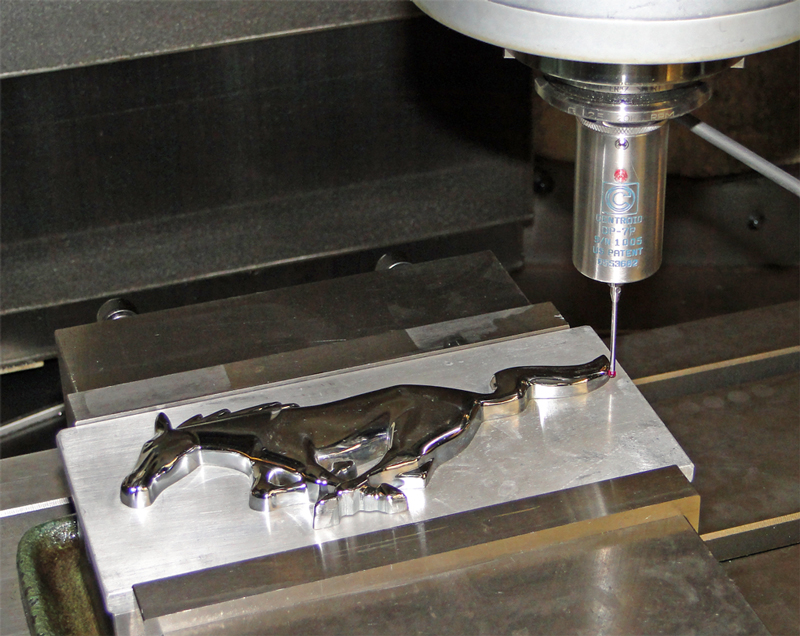

cnc milling digitizing machine parts centroid probe router mold making touch probes any machines haas tool mach3 setup way renishaw

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done varying direction on one or several axes, cutter head

A milling machine is a machine tool used for the complex shaping of metal and other solid materials. Its basic form is that of a rotating cutter or endmill which rotates about the spindle axis (similar to a drill), and a movable table to which the workpiece is affixed. That is to say, the cutting tool

The milling machine, itself, is easy to operate. Click on the image to see a larger version. As with any machining operation, you also need to give thought as to how the raw material will be held during the machining process (, clamped to the table or held in a vise) as well as corner limitations as

Operation of Milling Machine:- Milling machine is device that is used to remove material from the workpiece by feeding the workpiece past. Milling machine operation at high speed with feed to be fed against the worktable in rotating milling machine in X, Y ,Z directions.

machine bray zone tufts lab

To understand how a metal milling machine works, we will introduce you very quickly to the main types of those machines and how they process The vertical milling machines are the ones of the most common machines used for machining metal elements. What is special about them is that

A horizontal CNC milling machine (also known as a CNC mill) performing a milling operation on a metal part. Like most conventional mechanical CNC machining processes, the CNC milling process utilizes computerized controls to operate and manipulate machine tools which cut and shape

factory industrial jobs maintenance types different factories equipment workers general machine pooling cash assemblers safety common laborers working repair assembly

CNC Baron Milling Machine is turn-key, and easy to both learn and operate. The CNC Baron Milling Machine is durable with a cast iron body without the size of a larger machine. With the smaller frame of the CNC Baron, it is perfect for large and small manufacturing plants, machine shops, and a variety of other institutions that require the ...

How a CNC Mill Works. The CNC milling process follows the same steps many other machining types do, including making a computer-aided design (CAD) model, getting the CNC milling machine set up, and operating the machine to create the desired part.

milling machine’s knee rides up or down the column on a rigid track. A heavy, vertical positioning screw beneath ... finish and requires less power to operate. A plain helical-tooth milling cutter is especially desirable when milling an uneven surface or one with holes in it.

III Milling Machine Components. IV Types of Milling Machines. V How Many Axes? VI CNC Milling Operations. VII Suitable Materials. Machining entails both milling and turning but these two have distinct differences. Machining refers to a mechanical cutting technology that uses physical contact

feeder fish automatic pond koi feeding hozelock spring

How hard a ball mill operator has to work depends partly on himself, and partly on You, the operator, are supposed to control these actions in order to send on to the machines below you the right amount of The matter of feed to the ball mill brings up a point that is important in keeping you out of trouble.

For instance if the milling head of a milling machine is to be swivelled by a certain angle or the quill of a tailstock is to be moved, a further definition of Module Objective: With help of this module you learn to recognise general operating elements of the Sinu-merik Operate, and how to differentiate

Never operate a machine that you have not. been properly trained to use by a qualified person. Read the machine operator manuals. A wide range of tool types and configurations are available for CNC milling machines. Discussing every type, variation and use is beyond the scope of this course.

+machine/k0Experienced tradesperson required to operate CNC Horizontal milling machine in a general engineering workshop, in the St Mary’s area. Contact Jono on for more information. Qualifications & experience Experienced tradespersonTasks & responsibilities Operate CNC Horizontal milling machine in a general engineering workshop

13, 2021 · Klutch Mini Milling Machine is our 8th best mini milling machine that has a lot of good qualities that any good mini mill should have. Upon many features, we will go explain one by one on this klutch mini mill review. First of all, when we found the motor speed to be as good as ¾ HP, we were pretty much surprised.

Micro-mills look similar but operate in a different world than conventional cutters do… Makino says micro-milling involves features smaller than about ″ Plus, here's a video I made for Cutting Tool Engineering on how to increase Micro Machining Tool Life by reducing runout: 3. Care for

Equipment. Milling machines can be found in a variety of sizes and designs, yet they still possess the same main components that enable the workpiece to Milling machines can also be classified by the type of control that is used. A manual milling machine requires the operator to control the motion