concrete stone cement plastic paving molds slabs tiles flower abs stepping mold patio garden moulds path

ABS, short for acrylonitrile butadiene styrene, is a common engineering grade plastic that's used in many products around you, especially electronic enclosures. Its low melting temperature not only makes it ideal for injection molding, but for other applications such as 3D printing.

Learn how to use injection molding to mass produce plastic parts. Whether you're an experienced engineer or just getting started, this is your go-to guide for injection molding. The simplest way to deal with an undercut is to move the parting line of the mold to intersect with it.

Learn about DIY injection molding and all the tools necessary to utilize plastic injection molding in-house using 3D printed molds.

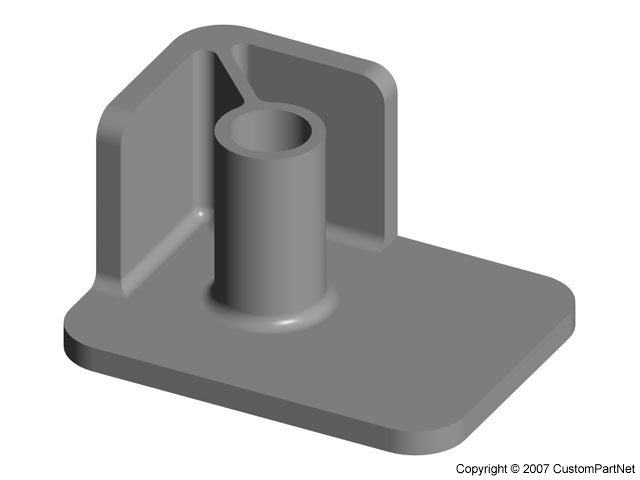

boss corner injection plastic molding ribbed defects process corners wu custompartnet

how to mold plastic. thermoforming auto part Vacuum forming auto parts Vacuum formed enclosure, plastic cover ABS high gloss material Able to do plating 1. Material : High gloss ABS 2. Produce method : vacuum forming / termoforming 3. Thickness : 4. We are able to

Do you want to know how to mold abs plastic? Find the advantages and uses of ABS injection molding plastic right

Two major categories could be ABS for extrusion and ABS for injection molding, then high and medium impact resistance. Even though ABS plastics are used largely for mechanical purposes, they also have electrical properties that are fairly constant over a wide range of frequencies.

molding: ABS plastic is melted and injected into mold cavity. Constant pressure is applied to allow for material shrinkage. The plastic then cools and hardens in the mold. Injection molds allows for uniform thickness throughout the entire piece. It gives the most accurate end product that fits well.

Molding plastic is a fun, inexpensive way to create unique pieces or replicas of your favorite items. You may purchase a mold or create your own custom molds out of reusable molding materials, silicone, and or plaster.

Midstate Mold highlights the versatile ABS plastic for injection molding. ABS - full name Acrylonitrile Butadiene Styrene - appears normally as an opaque polymer. Like all polymers, it's a copolymer of the three distinct monomer molecules in its name.

10, 2017 · Acrylonitrile Butadiene Styrene (ABS) Melting Point: Amorphous (no true melting point). Commonly 230°C: Glass Transition: 105 °C (221 °F) Injection Mold Temperature: 204 to 238 °C (400 to 460 °F) Density: – g·cm−3: Chemical Formula (C8H8·C4H6·C3H3N)n: Tensile Modulus: 310,000 PSI: Solublility

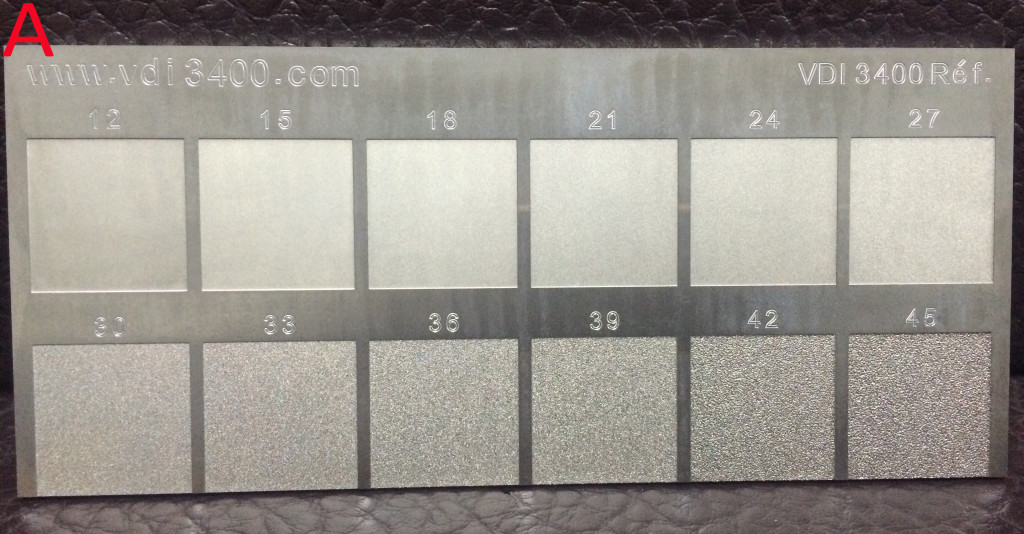

vdi 3400 texture finish mold edm spi standard plaques texturing surface comparison

Advanced ABS Plastic Injection Molding Capabilities. Stack Plastics has been using acrylonitrile butadiene styrene (ABS) to create injection molded parts and components for decades. Our expert team has extensive experience with this material and will work with you to determine whether ABS

mold injection die cast tooling plastic production casting ramko parts maker medical industrial cad ttm

out our wide range of plastic sheets. Our polycarbonate sheets are tough and highly impact-resistant. Our premium acrylic sheets come in a wide range of sizes and thicknesses. ABS sheets have high-impact strength with a textured hair-cell finish on one side. HDPE sheets make great chemical resistant work surfaces.

ABS plastic is a common thermoplastic polymer used for 3D printing prototype development and injection molded part manufacturing. Instead of burning, thermoplastics like ABS liquefy, which allows them to be easily injection molded and then subsequently recycled.

Chemical Resistance below how to mold abs plastic : Since most excessive gloss ABS resins are used in dwelling appliances and commodities, it must be resistant to oil stuffs akin to salad oil and DOP. A flexible thermoplastic, ABS has glorious dimensional stability and resistance to scratching.

thermoforming, discussed below, is related to this. Plastic Thermoforming. There are two types of plastic thermoforming: vacuum and pressure. Both processes involve heating and stretching plastic sheets over a male or female mold, pressing it into the mold, then trimming off the excess plastic.

Part design and mold design ABS plastic parts design requires uniform wall thickness, diversity of wall thickness should be controlled within 25 Molding temperature Molding temperature is a important parameter during ABS plastic molding, which is set to ensure ABS plastic material is

ABS plastics are a family of opaque thermoplastic resins formed by copolymerizing acry-lonitrile, butadiene, and styrene (ABS) monomers. ABS plastics are primarily notable for especially high impact strengths coupled with high rigidity or modulus. Consisting of particles of a

PC + ABS Injection Molding plastics offer improved strengths over ABS at a lower cost than Polycarbonate. Acetal Injection Molding Plastic are semi-crystalline. They offer excellent inherent lubricity, fatigue resistance, and chemical resistance.

ABS (Acrylonitrile Butadiene Styrene) plastic is a thermoplastic polymer often used in the injection molding process. The chemical properties of ABS plastic allows it to have a relatively low melting point and a low glass transition temperature, meaning it can be easily melted down and molded

molding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured; this process is known as …

roto lldpe 120l mold quadrati portatili muffa serbatoi armati carri rotomoldingproducts

concrete molds interlocking paver plastic precast pavers rubber mould cement tile africa moulds interlock mold brick sizes

Vacuum Forming Plastic that is Too Hot to Handle can be dangerous and fun! Let's Melt some Plastic and Watch it form to a mold! In this video, we'll take a look at how to best 3D print and tune ABS - and what ABS even is! There isn't just one type of ABS or ...

ABS - What does it stand for? How ABS is Made? Key Properties of ABS. It can be injection-molded, blow-molded, or extruded. It has a low melting temperature making it particularly suitable for processing by 3D printing on an FDM machine.

vdi 3400 mold surface sandblasting etching edm finish texturing texture grain plaques ref comparison making molding c1

the black mold and let the mixture sit for about 30 minutes to one hour. Scrub the area with the black mold using a sponge and the solution of your choice. Let it dry and repeat the process as needed to ensure that you’ve removed the mold. Safety Note: Always read the manufacturer instructions before using mold and mildew removers.

Video for How To Mold Abs Plastic How to Work With ABS Plastic - Amplified #164 How to repair and reinforce large ABS plastic

from our selection of plastic picture frames, card holders, and accessories today to stock up on must-have essentials for redecorating or visual merchandising. While shopping, don’t forget to register an account so you can quickly check out, print receipts, track orders, and make the most of your online shopping experience.

How concrete molds are made with vacuum forming. The first step in the mold-making process is to create a shape for the mold. For concrete molds, ABS or polystyrene are preferable. The plastic sheet is trimmed to fit the vacuum molding machine's capacity, then the plastic is heated so that

ABS treatment for plastic injection molding. Known as acrylonitrile butadiene styrene, ABS is an acrylonitrile - styrene copolymer of the There are several grades of ABS (especially flame retardant grade), after the plasticizing , its adhesion force is large on the screw, after long time it will decompose.

blow molding bottles crystal clear pe moulding mould larger

ABS plastic is strong and rigid, though, it has several downsides when it comes to 3D printing and molding with it. Learn more about ABS and its Yellowing of ABS is a result of the oxidation process. Overtime ABS plastic reacts with oxygen naturally but certain conditions such as heat and

Plastic injection molds are complex. Only experienced engineers know how to design and build them, meaning labor costs are high. Plastic injection molding relies on heating and cooling plastic. If a mold shape causes the plastic to cool in an inconsistent manner, your plastic part will be

For the ABS plastic injection molding, the relationship between temperature and melt viscosity is different from that of other amorphous polymers. In the melting process with the temperature keeping rising, the melt viscosity actually drops in a very limited range. Once reaching the

ABS molding is widely used to create some of the most durable and versatile plastic products on the market today. The skilled technical staff at Abtec Inc. specializes If you would like to learn more about ABS and how Abtec Inc. can turn your concepts into reality, contact us and request a quote today!

ABS injection molding plastic material is composed of 3 monomers: acrylonitrile, butadiene and styrene, each passes on different properties and conditions. ABS is amorphous and therefore has no true melting point. Thermoplastic (VS "thermoset") describes how the ABS plastic responds to heat.

Wondering what is ABS plastic and how it's produced? In the case of ABS, this plastic becomes liquid when it is subjected to 221 Fahrenheit degrees. What sets thermoplastics apart from other plastics is that they can be melted to their liquid form, cooled and again reheated without causing

Download our Injection Molding essentials for a fast introduction to plastic part design. It's a valuable resource that can save you development time Download this guide to explore the processes involved in creating sheet metal parts along with how to design common features and select the right material.

concrete edging molds mold edge stone border round plastic inch abs garden diy piece brick lot decor maker aliexpress wholesale

Properties of ABS plastic. ABS is an amorphous thermoplastic copolymer blended from Acrylonitrile, Butadiene and Styrene. Rebling design engineers have extensive experience in ABS plastic molding and optimizing ABS plastic part designs for functionality, cosmetics, cost and processing.

How to Build a Desktop Injection Molding Machine. ABS is a good material for applications where lower-cost commodity plastics do not provide the required combination of impact strength Molding draft angles. ABS is a rigid, but relatively soft, material that can often be molded with no draft angle.

Injection Molding Processability of the ABS Plastic Resin: Like PS, ABS is a thermoplastic with excellent processability and is able to be processed by general processing methods. The melt flowability of ABS is similar to that POM, which is better than that of PVC and PC, but worse than that of