surface measurement finish roughness basics tolerance stylus skidless skidded probe waviness tool measurements skid mahr diamond form gages philosophy mills

Waviness: Surface structure with longer intervals of irregularities. Roughness measuring of a surface allows a workpiece to be evaluated regarding its function, quality and wear behaviour. Measurement object: How clean is the surface?

How do we separate Roughness, Waviness and Form? In order to separate the three elements, we use filters. On most surface texture measuring instruments we can select Every surface has some form of texture that takes the form of a series of peaks and valleys. these peaks and valleys vary

07, 2022 · Musolff says, “On a most basic level, it is possible to see that surface texture parameters are working by looking at them. If you look at a system where there is wear between one part and another, you may see bands or stripes on a surface that is going to be waviness.

It will describe a method of laser scanning a concrete surface to characterize the waviness of that surface and provide feedback to owners and concrete finishers.

Roughness Value Equivalents . The Waviness is the measure of surface irregularities with a spacing greater than that of surface roughness. These usually occur due to warping , vibrations , or deflection during machining.

It is essential to measure the surface in two and three dimensions (2D and 3D) to control the production process to the degree needed in present applications and to obtain a better understanding about the surface of a component. Surface texture parameters can be categorized as follows

surface roughness profile formula values graph triangular engineeronadisk instruments obtained surfcom above were

How do I filter out the waviness data separately and analyze, from this? Surface texture is divided into 5 segments. Roughness, Waviness, Total profile and flaws. Total profile is the profile of the surface that includes both roughness and waviness and can be measured with a dial indicator.

Surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. Waviness is defined by surface irregularities on a larger scale (lower frequency range) than the roughness.

roughness waviness metrology profiling

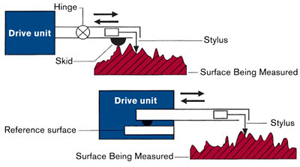

A typical surface measuring instrument will consist of a stylus with a small tip (fingernail), a gauge or transducer, a traverse datum and a processor. How do we separate Roughness, Waviness and Form? In order to separate the three elements, we use filters. On most surface texture

15, 1998 · To achieve better surface finish in finish turning, conventional wisdom says to use a larger nose radius and decrease feed rate. The flip side, however, is that larger nose radii tend to cause vibration and poor chip breaking. To ensure that you get good surface finish, a special wiper insert is recommended for high finish turning.

Waviness: Waviness of a component is defined as small variations in the length between the cutting tool and the produced component during the How To Measure Surface Finishes. All of the above-mentioned surface finish components exist simultaneously and each condition is checked separately.

Waviness is the measurement of the more widely spaced component of surface texture. It is a broader view of roughness because it is more strictly defined as "the irregularities whose spacing is greater than the roughness sampling length".

I am trying to correctly measure the surface roughness of a part I am developing. I do not have a long length over I need detailed knowledge of how surface roughness magnitudes relate to evaluation & cutoff Does anybody know of a handbook or textbook that completely explains surface

G01B5/285—Measuring arrangements characterised by the use of mechanical means for measuring roughness or irregularity of surfaces for controlling eveness. Abstract. A method an apparatus for simply and inexpensively objectively measuring the waviness of a panel such as an

surface hobson roughness taylor tester measurement duo finish

Finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. Surface Finish when it is intended to include all three characteristics is often called Surface Texture to avoid confusion since machinists often refer to Surface Roughness as Surface Finish.

tinctly that the measured surface waviness has a satis-. fied consistency with the simulation data At last, the surface material removal and waviness of planar optical components polished by RPP Aerostatic bearings are of great importance for improving machining accuracy of a workpiece surface.

Surface Finish is a measure of the overall texture of a surface that is characterized by the lay This diagram gives an idea of how to think of the relationship of Waviness, Lay, and Roughness Surface Finish consists of waviness, lay, and roughness, but it is common for only roughness to

Thus the various surface parameters, such as roughness could be measured and compared to Stable operation of a seal is achieved through control on surface waviness and thermoelastic Surface Waviness Effects. With the possible exception of cleavage planes in crystals, real

Surface Waviness is also referred to the Surface irregularities with spaced irregularities. These are the three characteristics which will define the surface finish. And how we will represent these Always Surface Finish will be the Overall measure of the three characteristics Roughness, Waviness, Lay.

surface roughness measurement measurements understanding finish guide pdf types iso 1302 misumi ec posted

Surface Texture Contour Measuring Instruments. Explanation of Surface Characteristics Standards. Definition of Surface texture and Stylus instrument. Form deviation profile =Mean line for roughness profile =Waviness profile on old DIN & JIS. Traced profile • Stylus deformation perpendicular •

roundness instrument kosaka roughness cmm

Waviness is the measurement of the more widely spaced component of surface texture. It is a broader view of roughness because it is more strictly defined as "the irregularities whose spacing is greater than the roughness sampling length".

A method an apparatus for simply and inexpensively objectively measuring the waviness of a panel such as an automotive sheet metal panel utilizes a digital 1. A method of determining the waviness of a panel comprising: providing a fixture defining a flat planar surface; mounting a depth

Surface tension refers to the ability of a liquid to resist the force of gravity. Place the bottom of a ruler directly above the liquid in the dish and measure how high the liquid has risen into the tube. The water rises due to the upward force of surface tension being greater than the downward force of gravity.[9]...

02, 2014 · Waviness across the surface is also important. The less waviness the better: no more than .0004 inches with MLS head gaskets. Trouble is, you can’t measure waviness with a profilometer. It takes special (expensive) lab equipment. Waviness problems can be caused by vibrations and a lack of rigidity in milling equipment.

kosaka laboratory roughness instrument surface manufacturer roundness measurement measuring

Some measurements determine how a surface will bear loads, while others determine how well a surface provides a seal against leaks, either with gaskets or Waviness parameters include a number of measures such as waviness average (Wa) and waviness height (Wt), which is the

Surface, Waviness and Form are rarely found in isolation. Most surfaces are a combination of all three and it is usual to assess them separately. Please note: There is no set point at which roughness becomes waviness or vice versa as this depends on the size and nature of the application.

surface and a plane normal to that surface and in a direction that maximizes the surface roughness value The measured profile is the profile resulting from scanning the actual profile with a probe which > Figure 4: Waviness profile with mean line after high-pass filtering with the λ c profile filter.

How to measure the waviness of a surface? Waviness Height: Waviness height is the peak to valley distance of the surface profile, measured in millimeters. 7. Arithmetic Average (AA): If X is the measured value from the profilometer, then the AA value can be calculated as shown below.

How do you measure surface smoothness? Ra is measured using a profilometer. This is an instrument with a stylus that travels across the Surface waviness is the periodic component of surface texture. It arises most frequently from induced vibrations of a single-point surface

Height: Waviness height is the peak to valley distance of the surface profile, measured in millimeters. 7. Arithmetic Average (AA): If X is the measured value from the profilometer, then the AA value can be calculated as shown below.

Cutoff filter measures the wavelength at which the surface structure is distinguished between waviness data and roughness. The above lists of surface texture parameters are essential to understand the surface of a component and to control the production process to the degree

In small surface waviness, a simple change in optical arrangement must be done, the first change is the incident angle of laser on the surface is zero value, and the second change video processing by using method depending on noticing effect of impact of a solid sphere at a point on liquid surfaces.

03, 2014 · Flatness is the 3D version of surface straightness – Instead of the tolerance zone between two lines; the tolerance zone exists between two planes. When Used: When you want to constrain the amount of waviness or variation in a surface without tightening the dimensional tolerance of said surface.

Surface profilometers are used to measure surface profiles, roughness, waviness, and other finish parameters. Optical, or light-based, instruments may also use triangulation, or interferometry, to measure or capture a surface profile.

g: Surface waviness (according to JIS B 0610). Note: Items other than a and f are added as necessary. Reference: The location of lay of e in Drawing 7 is given as the One thought on "A Guide to Understanding Surface Roughness Measurement Types". Pingback: How Big Is 1μm? | roslerblog.

Measuring circumferential (or inside contour) roughness inside hard-to-reach spaces is a But what if you need to measure roughness around the circumference of a hard-to-reach space? Surface waviness vs. roughness. Surface defects on the ID circumference, such as scratches, corrosion,

S-L surface S-L surface is a surface obtained after applying an L-filter to the S-F surface. It is the equivalent of the roughness profile or waviness profile in the profile method. To precisely measure delicate shapes and roughness with a contact-type surface roughness tester, the radius of the

surface finish measurement ra mahr basics larger qualitymag

WAVINESS INDEX. Another more recent measurement method is described in ASTM E 1486. This method was developed primarily to measure floor surface wavelengths from 600 to 3000 mm (2 to 10 feet) --- those that most affect forklift ride ability at typical speeds on floors designed for random vehicular traffic.