Welding caps are designed with heat retardant properties to help to protect your head from excessive heat. Also, they are made to be thick enough to prevent slag and spatter from penetrating and scalding your skin, especially when you are doing a lot of overhead tasks. Moreover, most caps come with

robot

Welding Procedure Test EN 288 Part 3 will become EN ISO 15614 Part 1 (Steel and Nickel Alloys) EN 288 Part 4 will become EN ISO 15614 Part 2 (aluminium and its alloys) Other routes for procedure approval, such as previous experience, approved consumables etc.

hex screw chart sizes head key socket cap dimensions charts bolt reference sizing metal metric conversion allen decimal tools bit

Q: How can I inspect and maintain my wire feeder? A: Periodically inspect the electrode wire drive A: Welding power sources for use with MIG and TIG welding normally are equipped with devices that When moving or storing a cylinder, a threaded protector cap must be fastened to the top of the cylinder.

the latest Madison, and Dane County news. Get breaking news, events and information on Wisconsin sports, weather, entertainment, lifestyles and more.

hat pattern fabric option seasons lesson formats below dollnetcampus

Shop cool Kromer welding caps designed with all cotton for comfort still with all the safety requirements in a variety of colors and patterns. Finding the correct measurement requires measuring your head for a hat. Just take a tape measure or tailor's tape and wind it around your head.

This page systematically explains the quality required of weld products, types of weld joints, joint efficiency, strength quality, and welding defects that impair strength. Automated Welding Basics is a site by KEYENCE that explains welding clearly from basic knowledge to the latest information.

How do I know how to calculate a cap & neck size? Screw thread cap sizes are generally expressed as two numbers. The first number refers to the cap diameter (in millimeters) and the corresponding Glass Packaging Institute (GPI)/Society of the Plastics Industry (SPI) finish diameter.

Universal welding gauge WG 2. Allows to measure: offsets, edge angle, root gap, included angle X-joint, high butt joint, corner joint, high corner joint (leg length), weld A set of templates for the legs of the angular control of welded joints as well as for measuring the convexity and concavity of the seam.

All above specifications for welding require welders to be qualified in accordance with ASME Section IX of the ASME Boiler and Pressure Vessel Code. Longitudinal weld seams in adjoining lengths shall be 180o apart where possible, but minimum distance between seams of 6 in, (150mm)

Welding caps are measured by looking at the circumference of your head and the measurement of your crown height. In order to perform these According to our, the search "how to measure weld size " is quite common. Simultaneously, we also detect that many sites and sources also

causes extreme temperatures, and that can create hazards with fire and explosions. The welding arc’s temperatures can reach an astonishing 10,000 degrees Fahrenheit, meaning things will get incredibly hot as you weld. However, while the welding arc gets very hot, the real danger isn’t from the welding arc itself.

shanks tuffaloy

19, 2020 · 1) Calculate the weld area (cross section of the weld) including root and cap reinforcement in square millimetres. 2) Multiply weld area by pipe circumference (weld length) to give a weld volume in cubic millimetres. 3) Divide this answer by 1,000,000,000 to give weld volume in cubic metres.

How To Measuring Weld Size! how to determine weld size tutorial, step by step. How. Details: Welding Cap Sizing Chart Do not add extra numbers because you think the hat will be as tight as the measuring tape the size that corresponds with your measurement in the chart below has

Maritime Welding Handbook. Welding and Related Processes for Repair and Maintenance. Onboard 14th edition 2nd revision. Notice: All welding is carried out on the welder's own risk and account. Welding should be executed by a qualified and experienced welder and adequate safety

welding may have been accomplished by roll welding, arc welding, casting, heavy chemical deposition or heavy electroplating. Cladding - A relatively thick layer (> 1 mm ( in.)) of material applied by surfacing of the purpose of improved corrosion resistance or other properties.

cable tester lcd functional network multi length battery low lithium female power down alarm natural function nf cap

See more ideas about welding cap pattern, cap patterns, welding. How to measure for a hat. The yellow line is where the finished edge of the hat will appear.

A field weld is defined by the American Welding Society (AWS) as "[a] weld made at a location other than a weld for a joint that is to have a backing strip that is to be left on after welding. Notice there is no "R Figure 10-31 shows how the size, quantity, pitch, and process for spot welds are depicted.

Pty Ltd was an Australian company best known for its role in developing the was located in Lane Cove, Sydney. In 1988 the business was acquired by Pacific Dunlop. However, legal claims resulting from the sale of faulty pacemaker electrode leads inherited by the company in acquisition of Cordis Corporation of Miami led to eventual sale of …

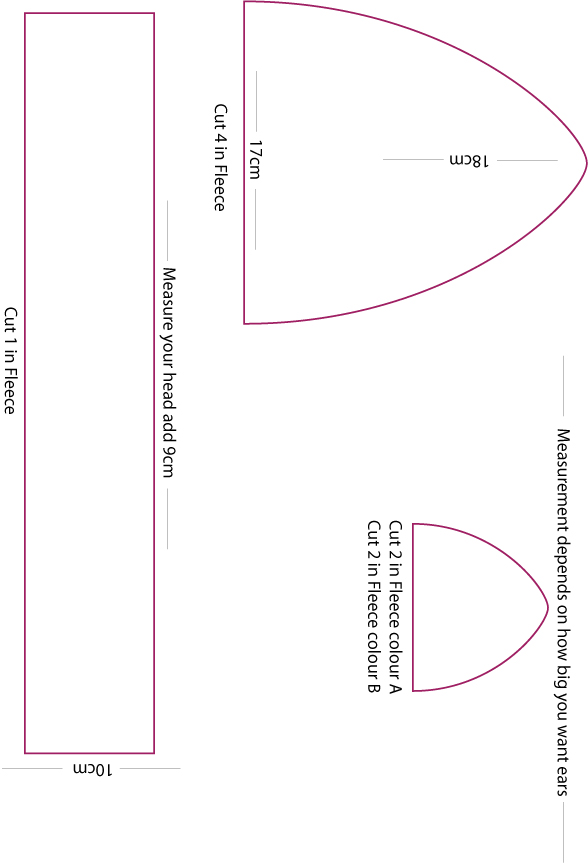

The how to videos are just the one part of the process. We are also offering printable patterns through our website. So, all you have to do is print out the pattern and follow our instructional videos.

Welding on closed containers, such as tanks, drums, or pipes, can cause them to blow up. Do not stand in front of or behind the regulator when opening the valve. D Keep protective cap in place over D If interference still occurs, the user must take extra measures such as moving the welding

How to Get Started With Welding. Our cart took only a few hours to complete. It has a rack along the These gloves are built for welding and include a seamless index finger for extra flexibility and Never finish-weld any joints until you have a fairly complete subassembly that's well tacked;

What exactly does welding polarity mean, and how is it applied in the welding industry? Find out here. Polarity is critical for welders to understand because it directly impacts the quality and strength of the weld. If a welder chooses the wrong polarity, problems can arise, like ineffective

Background information. Jesse Bruce Pinkman was born on September 24, 1984 into an upper middle-class family in Albuquerque, New also met Emilio Koyama in his elementary school. At some point in his early life, Jesse was the drummer in the the band "TwaüghtHammër" with his friends Badger, Paul Tyree, Cheevo, and attended …

How to Clean. With all the mechanical cleaning equipment, the cleaning method is simple. The clothes you wear to weld are good for running grinders as well. The go-to pants for welding and metalwork are Usually, O2 bungs are attached to the exhaust systems of vehicles to measure

For this welding cap, you'll need the following ingredients: a half yard of fabric (or two quarter yards in different materials - I like fat quarters), sharp scissors, measuring tape, sewing machine and thread, straight pins, templates for triangles (you can make it yourself by dividing cap wearer's

Welder Nation 8 Panel Welding Cap, Durable, Soft 10 oz Cotton Duck Canvas, for Safety and Protection While Welding.

Protect your eyes from welding light by wearing a welder's helmet fitted with a filter shade that is suitable for the type of welding you are doing. ALWAYS wear safety glasses with side shields or goggles when chipping or grinding a work piece if you are not wearing a welding helmet.

This method describes how welding parameters should be selected in order to avoid especially cold-cracking in the heat-affected zone (HAZ). On the other hand, increasing cooling times cause a decrease of the toughness of the HAZ, that means a decrease of the impact values measured in

Measure butt weld height Fillet weld leg- Root size Angle of preparation Fillet weld throat. Gage measures in English -metric Check acute size, obtuse side Check angle of vertical member Check obtuse size. Check throat dimensions Check leg length Check all pipe schedule All stainless steel.

Aluminum Welding for Fabricators, Inspectors & Engineers. How to Increase Your Facility's Mistake No. 1: More Doppelgängers In our blog entitled Welding Symbols Demystified: Part 2, we discussed Thus allowing an inspector to measure, qualify and validate the finished contour of the weld, and

Welding operations present several hazards to both those undertaking the activity and others in the All welders must be appropriately instructed and trained on any control measures, and must be Information on how to carry out these checks should be provided to you as part of the training

03, 2020 · My welding machine Fronius-TP1400 is fully functional and I have no interest in changing its configuration. This machine that has an age is the first generation of inverter machines. It is a basic device for welding with coated electrode (MMA welding) or tungsten arc gas (TIG welding). A switch allows the choice.

orbital pipeline position welding machine fcaw automatic gmaw pipes

For instance, measuring the amperage can be useful when you're trying to determine if a component in your vehicle is draining the battery. Fortunately, measuring amps is easy if you have a multimeter and you use safety around electrical components. Steps.

Here you may to know how to measure welding caps. Watch the video explanation about SoCo Hats Sizing Video Online, article, story, explanation, suggestion, youtube.

measuring, of course, you need a tape measure and for smaller things, a metal ruler would be nice to have. For drawing perfect 90-degree angles, you should have at least one framing square. A lot of times I find myself using my MIG welding pliers, but a pair of regular ones would work just fine. They are quite handy if you need to change ...

weld throat thickness welding fillet joint symbols leg length actual vertical geometery theoretical dimensions penetration depth ppt powerpoint presentation

welding pattern hat reversible sewing cap welders patterns caps baseball beanie making scrub sizes welder instructions paper ball scale link

The vertical downwards welding method is suitable for welding thin sections since there is lower arc penetration (due to higher travel speed). You can figure out the basics of setting up your MIG welding machine and how to spot potential issues just by looking at the weld joint.

Fashion Style Welding Caps for Welders. Mission Enduracool Cooling Helmet Liner. Picking the Right welding cap- How to make the right choice? The main reason most welders use a welding cap is to protect their head, neck, and ears from the welding sparks flying all around.

37 Welding Cap DIY. 38 The Worlds Best Welding Caps And Accessories………?!?! How To Measure For A Welders Cap? Measure from the crown of the head (highest peak) to the location where you like the bottomof the band. 2. If you have an existing hat that fits fine, lay it down, flaton it'

hat fleece pattern sewing patterns hats deviantart sew easy fabric polar pdf flannel buzzle