mrf polishing magnetorheological finishing technology optics paper edmundoptics correction

How to measure flatness. A basic prerequisite for machine installation is that the base is flat. It is also a requirement for machine tables, so that The measurement of flatness/twist on circular planes such as flanges is also based on the use of three reference points, situated at intervals of 120° around

Instead, optical gauges which measure manifest flatness (flatness not hidden by tension) can be attractive The more tension that is applied, the less flatness remains manifest. To calculate how much Dr Pär Kierkegaard, Automated optical flatness measurement for flat metal

•Measure from bottom side •PRO: Fast set up time •All three jacks are exact same height •CON: access •Optical Flats – uses fringe patterns •PRO: Fast reading •CON: You must have the correct size and be careful.

Flatness measurements are performed in various ways across the ZYGO product line. High quality transmission flats (up to λ/50) allow ZYGO laser interferometers to measure flats for space telescopes down to ground steel surfaces. Mx™ software extends the flatness metrology application space

to Measure Flatness - Technical Article. There are a number of ways to measure the flatness of a surface. The most common method within the Flat Lapping sector is by using a Monochromatic Sodium light unit and an Optical gives extremely precise measurements, more accurate than most CMM measurements, in an economical way.

I What is Flatness? II Flatness vs Other Characteristics. III How to Show Flatness on a Drawing? It may seem like flatness is very similar to other geometric as well as regular tolerances in terms of the final result. To measure flatness with a height gauge, we need to hold the reference feature parallel.

flat. Most flats have two perpendicular diamete~s which are identified as A-B and C-D by markings on One-dimensional" Flatness. The objective of the 2-flat method is to measure the profile of the. Although the surface of an optical flat is often used as a two-dimensional reference plane, it is

Flatness Measurements with Optical Flats. An optical flat is a glass, fused silica, Zerodur or sapphire disk polished to a high degree of flatness, typically within a few millionths of an inch, and is used as a reference to evaluate the accuracy of flat surfaces. Measuring flatness using an

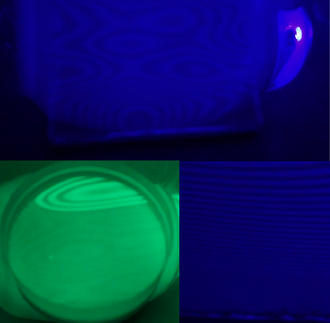

Optical flats are measured for their accuracy through the fractions of a reference wavelength. Surface accuracy is derived from the amount of curve and spacing between the interference fringes. If the interference fringes are straight and parallel, then the tested surface has a flatness more than

Hold the optical flat steady with one hand and draw the paper out from between the work piece. Where the surface to be measured is irregular, the contact method of flatness testing is recommended. Here the flat is placed in the most intimate possible contact with the work piece

Optical flats are cylindrical in form with the working surfaces flat and are of two types: Type A—It has only one surface flat. Type B are used for testing measuring surfaces of micrometers, measuring anvils and similar length measuring devices for testing flatness and parallelism.

Explained working of optical flat for checking surface flatness. We show how to use a sodium monochromatic light and a Quartz Optical flat to get light band readings on mechanical seals and ...

Using a monochromatic light and optical flat to measure flatness.

Optical flats are plates with one or two surfaces of very high optical quality and flatness. They are mainly used as highly flat reference surfaces in interferometers for checking the flatness of optical elements.

for Parallelism and Flatness. In theory, if an optical flat is in perfect contact with a perfectly flat anvil, then no light bands will be visible. Make sure the optical flat and anvil are clean. Attempts to wring the optical flat will only scratch the glass. Get a good fit by gently squeezing the optical flat onto the surface.

talysurf hobson absolute position zygo zps

An optical flat is an optical-grade piece of glass lapped and polished to be extremely flat on one or both sides, usually within a few tens of nanometres (billionths of a meter). They are used with a monochromatic light to determine the flatness (surface accuracy) of other surfaces, whether

to Measure Flatness with Optical Flats by Van Keuren Introduction The easiest and best way to test the flatness of a flat lapped or polished surface is with an optical flat. Such surfaces are found on micrometers, measuring machines, gage blocks, snap gages, ring seals, valve seats and precision flat lapped parts.

jariya

measure contours with optical measuring instruments. Contour & roughness. ... flatness, straightness, coaxiality and other measuring tasks. From manual to fully automated. ... Powerful MarOpto Fizeau interferometers can provide contactless measurements on flats and spherical surfaces.

section contains multiple choice questions and answers on tool makers flats, high precision surface plates, angle plates, v block, bench centres, spirit level, combination set, radius, angle and feeler gauges, vernier and master height gauges, universal measuring instrument, micrometers, bench micrometer, graduated scales, slip gauges and ...

How To measure flatness: The best way to get a reliable measurement reading is to have the probe underneath the part. Measuring flatness with a height gage: To use the height gage correctly, the part to be measured is first placed upon 3 columns with adjustable heights.

flatness of an optical flat is measured in fractions of a reference wavelength, A λ/20 flat will have a maximum peak to valley deviation of or We offer several levels of flatness for our single surface flats : λ/4, λ/10, and λ/20.

Conventional measurement methods for large flat mirrors are generally difficult and expensive. In most cases, comparison with a master or a reference flat similar We describe using two electronic levels to measure flatness of large mirrors. We provide measurement results on a flat

How to Measure Flatness with Optical Flats by Van Keuren Introduction The easiest and best way to test the flatness of a flat lapped or polished surface is with an optical flat. Such surfaces are found on micrometers, measuring machines, gage blocks, snap gages, ring …

Making optical flats is harder than making spherical surfaces. A sphere is self generating but not so a flat. Flats are usually done on a planetary lap which is Some are accurate to 1/10 lightband, but how can it be manufactured in the first place if they are supposed to used to measure flatness at a

(Note: the optical flat must always be more accurate than the surface being inspected). How to read light bands Interpretation of interference band patterns is fairly Measuring Flatness With Light Band Readings Sample Flatness Interpretations Drawings no. 1 - 6 show sample light band readings on

is more easily measured with a co-ordinate measuring machine. But neither of these methods can measure flatness more accurately than about μm ( × 10 −5 in). Optical flats in a wooden case

Optical flats can be described as an optical grade glass which is polished and made extremely flat An optical flat is placed on a surface, in order to measure its flatness, before a monochromatic The main applications of optical flats are listed below: Calibration of flatness of various optical surfaces.

•Able to measure linear flatness, and spherical dimensions within tolerances to .000002 in. Turning Centers • 1 – Mazak Nexus 400- 11 (with Scales) CNC Turning Center (23” Dia. x 40”) ... •6 – Optical Flats to 12” ...

With flatness, you can allow the table to be flat without constraining the tabletop thickness very tight. (You would be rejecting tables that were good thicknesses and normally in spec if using GD&T). what is different in the following flatness specification of a wheel and how to measure the latter one?

I use optical flats for checking flatness of parts after flat lapping. Lapping on a conventional cast iron lapping plate gives dull (but very flat) surfaces - unsuitable for inspection by optical flat. Trick of the trade is to make the surface a bit

An Optical Flat is a glass claimed to be extremely flat on one or both sides. it will be used to determine the flatness with Optical Flat. The most common interference effects are associated with thin transparent films or wedges bounded on at least one side by a transparent surface.

An optical flat is a precisely polished flat surface, used as a reference against which the flatness of an unknown surface may be compared. Edmund Optics offers both single surface and dual surface optical flats in either ZERODUR® or Fused Silica. The flatness of an optical flat is measured

Techniques for Measuring Flatness. Thread starter Cullet. Start date Oct 8, 2009. In order to measure the flatness of the surface, the part would have to rest on blocks (or some reasonably flat plane) with the target surface Variations in Tool Use Techniques and How to Improve Consistency?

optical flat is an optical-grade piece of glass lapped and polished to be extremely flat on one or both sides, usually within a few tens of nanometres (billionths of a meter). They are used with a monochromatic light to determine the flatness (surface accuracy) of other surfaces, whether optical, metallic, ceramic, or otherwise, by interference. When an optical flat is placed on …

Explained working of optical flat for checking surface flatness. Flatness is an often misrepresented property of our own intuition. Many of the objects we consider flat, pale in comparison to ... How to Measure the Surface of a Plano Optic with a ZYGO Laser Interferometer System.

View Crossmark data. Flatness measurement of large flat with two-station. We present a method that accurately measures large optical surfaces before polishing using a laser tracker. Using the scanning mode of the laser tracker considerably improves measurement efficiency and minimizes

I am trying to understand how optical flats are used to measure the surface flatness of an optic. However Edmund optics' spec sheets indicate both surfaces of their flats are coated. Furthermore, the measurement technique doesn't specify that the secondary surface of the optic under test must

zygo surface newview optical metrology interference microscope interferometer profiler features

flatness measuring kemet measure equipment gauges gauge lapping surface chart optical finish flats technical

Then take a tape measure and a flat floor and measure from the floor to the specified point on the car. Electronic bottleneck refers to the inability of electronic devices to process optical data at very high speeds. The term is used mostly when trying to justify the need to process ultra high speed

450nm

What are Optical Flats and how are they used? An optical flat is a contact optical measurement device used in conjunction with a monochromatic light source to measure precision flat surfaces. A monochromatic light source must be used to accurately determine flatness with an optical flat.

How to Measure Flatness - Technical Article. There are a number of ways to measure the flatness of a surface. The most common method within the Flat Lapping sector is by using a Monochromatic Sodium light unit and an Optical Flat .