Dew point pressure is defined as the pressure at which the first droplet of liquid appears at a specific temperature. Several correlations are available to calculate dew point pressure from basic information. These correlations can be grouped in three categories: (1) correlations that depend on

dew point humidity relative temperature measurement piping compressor especially systems delta voor

Dew point temperatures in compressed air range from ambient down to -80°C (-112°F) in special cases. Compressed air systems without air Users often ask how pressure dew point is reliably measured in compressed air. Some principles of measurement apply to all types of instruments

Monitoring Compressed Air Quality Through Moisture Measurement. provide protection against moisture. There are two main questions that arise when taking dew point measurements in a compressed air system: · Should the sample be measured at atmospheric, or at line pressure?

Compressed air used for instruments is generally at 100 psig. My doubt or confusion is how do I calculate the water content for a compressed air at 100 psig with a dew point of -40 C? I measured the dewpoints of line and other equipments several times during a pre-commissioning of our

Installation Dew point in Compressed Air Systems Refrigerant dryers Desiccant dryers Things to consider when choosing a dew point sensor Page 2 / 2014 How is Dew Point Measured Reliably? Air compression increases vapor pressure and thus dew point. = water vapor Vapor pressure

Moisture in compressed air used in a manufacturing plant causes problems in the operation of pneumatic air systems, solenoid valves and air motors. To specify a dew point lower than required for an application is not good engineering practice. (Naming a pressure dew point is how to state

Pressure Dew Point in Compressed Air: What Is It and How to Measure It. May 26, 2020. The generation of compressed air used in industrial As a result of the damaging effects of excess water accumulation in compressed air systems, plant managers must ensure their personnel

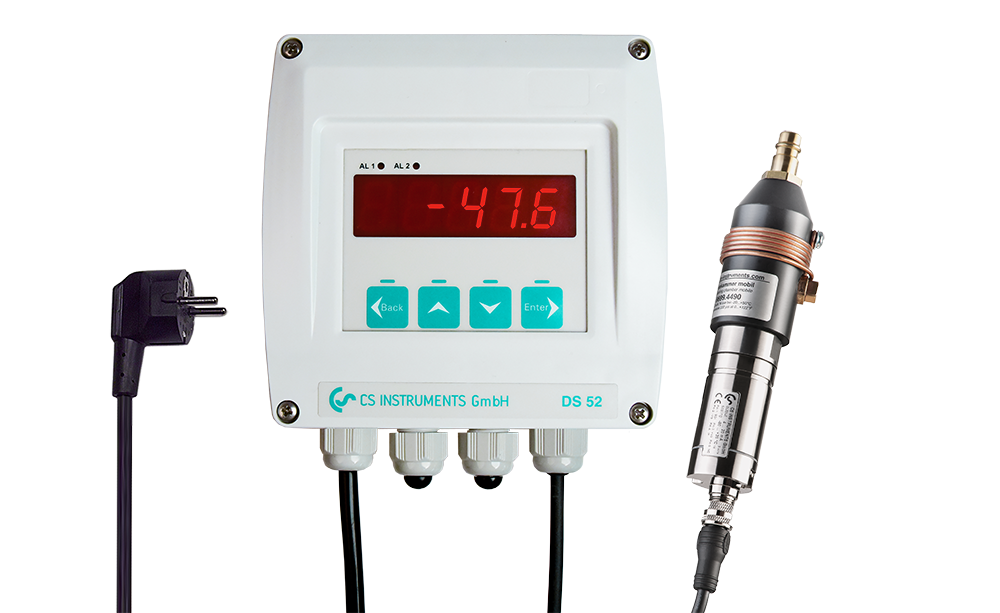

For adsorption dryers of compressed air, medical compressed air and nitrogen gas. Measures dew point in the range of -60° to +30°Ctd, - 80° to +15° CtdA. Convenient operation via display menu with compact design with rotatable housing by 350° with variants with/ without display available.

Measurement. Devices called hygrometers are used to measure dew point over a wide range of temperatures. These devices consist of a polished metal mirror which is cooled as air is passed over it. ^ "Dew Point in Compressed Air - Frequently Asked Questions" (PDF).

The dew point is the temperature at which air becomes saturated with water vapor after being cooled by removing sensible Meteorologists use dew point in the fields of agriculture and aviation to calculate the probability of fog, carburetor icing, or crop damage.

Dew point temperatures in compressed air systems range from as low as -112°F (-80°C) in extreme cases. If the compressed air system doesn't have drying capabilities, then it will tend to produce compressed air at an ambient temperature. That is why industrial compressed air users use

how online sensors measure the DEW POINT of Compressed air & quantitative Moisture measurement [in PPM]..? we have installed one in our comp air header line [250 NB] which is showing DPs like 32 - 35 deg c which seems comp house has 4 nos of 3 stg

Portable Dew Point Meter is designed to measure the performance of drying systems for compressed air, nitrogen, transformer SMC demonstrates how to remove water from factory compressed air with minimal loss of air flow and air pressure.

cfr unintentional

The pressure dew point transmitter METPOINT DPM precisely measures the critical parameters of the air with temperature, relative humidity and dew point. The ideal instrument for monitoring residual moisture is the pressure dewpoint sensor METPOINT DPM. Our sensor technology enables you

I'm compressing ambient, undried air so that I can sparge it into a tank to aerate the contents. Hence the air could have any RH at inlet conditions, even 100%. Look at the saturated steam tables for the temperature that corresponds to Pv. This is the dew point temperature you are looking for.

donaldson druckluft comprimido compressa

The pressure dew point means the temperature to which the compressed air can be cooled without condensate precipitating. The pressure dew point depends on the final compression pressure.

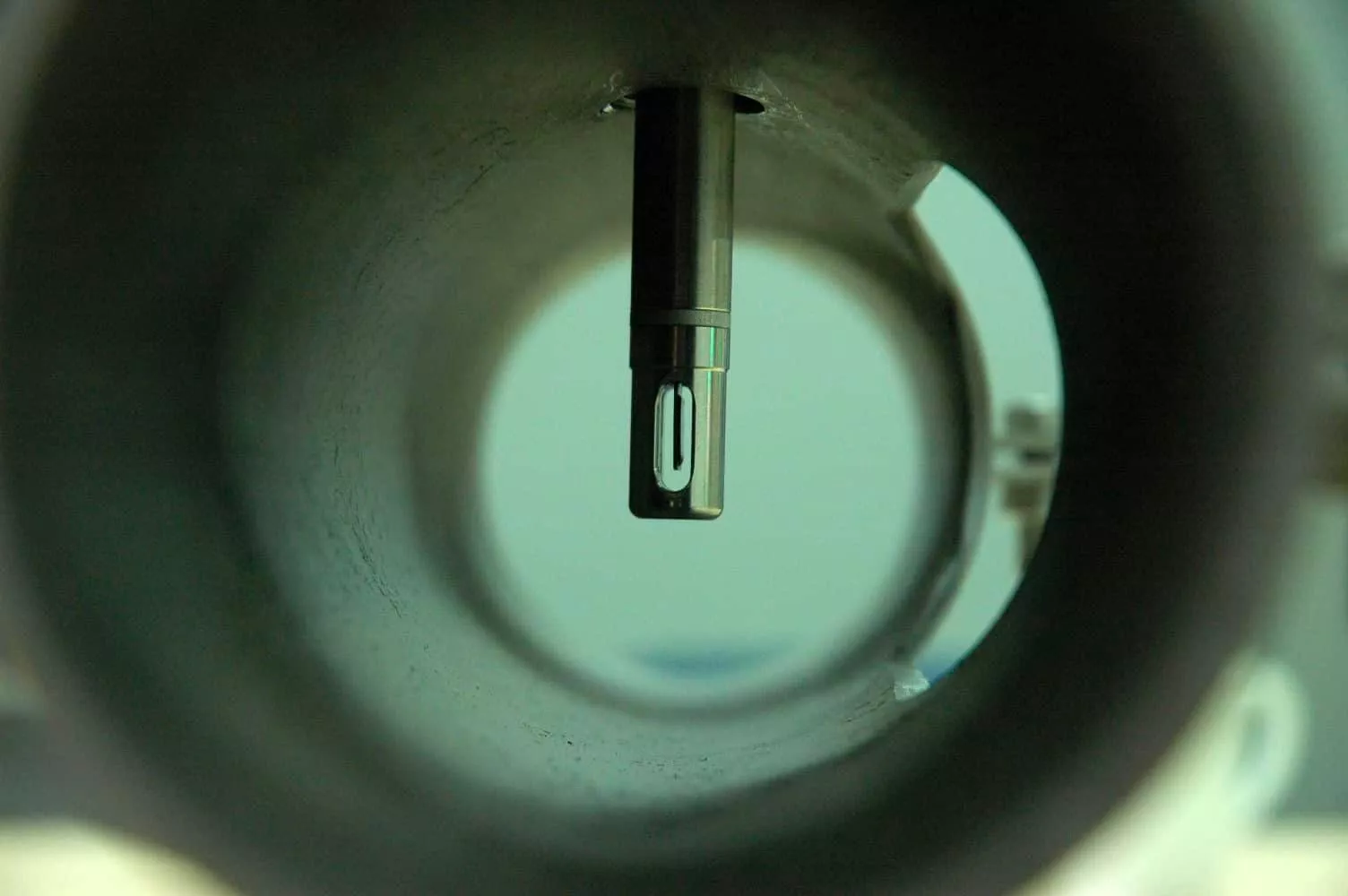

probe vpinstruments

Industrial compressed air and gas systems can suffer damage from water contamination directly or through the water subsequently freezing and expanding. Measuring the dew point can be a simple process and should be continuously monitored according to the plant risk analysis recommendations.

refrigeration dryers measurement desiccant ds52

beko technologies air calidad alta compressed systems condensate monitoring ltd airmatic compressors demonstration analysis equipment siguiente anterior

A dew point meter is used in compressed air systems to ensure the air quality which is used in the production and throughout all the processes in a Easy and affordable sensor solution to measure the compressed air flow and consumption. Sensor is calibrated in the measuring section, this allows

Relative Humidity vs. Dew Point in Compressed Air Systems. Do you know how to calculate dew point and relative humidity for your compressed air system? Understanding these measures and how they are related will help you maintain your compressed air system at optimal performance.

How to find the dew point in buildings, when does moisture condense on surfaces and in cavities. How to Predict or Calculate a Wall Cavity Dew Point or Condensation Point in Buildings. This also means that if you are measuring the relative humidity in a room, the RH number only has meaning

For most compressed air applications, monitoring the dew point and making sure your compressed air doesn't reach its' dew point is critical to keeping your business running efficiently and effectively. Dryers are essential in keeping your compressed air cool and free of moisture and contaminants.

Dew point temperature is a measure of how much water vapor there is in a gas. Water has the property of being able to exist as a liquid, solid In many modern factories, compressed air is used to operate a variety of equipment, some of which may malfunction if condensation forms on internal parts.

Learn about dew point and why it's important to monitor from experts at RoFlo Compressors. The air near the outside of the glass has been cooled below its dew point temperature and water from The dew point is the temperature (at a given pressure) at which a fluid will change state from a

Learn about the compressed air dew point, how to measure dew point of compressed air, and why it matters to your industrial profits and uptime. This compressed air standard sets forth testing parameters designed to maintain proper purity levels in compressed air.

dew point portable air monitors kahn meters

The dew point is the temperature to which air must be cooled to become saturated with water The rate at which perspiration can evaporate depends on how much moisture is in the air and how much moisture the air can hold. Measurement. Devices called hygrometers are used to measure dew point over a wide ^ "Dew Point in Compressed Air - Frequently Asked Questions" (PDF).

How is Dew Point Measured Reliably? Monitoring with alarming and real time trending. Air compression increases vapor pressure and thus dew point. Dew point temperatures in compressed air range from ambient down to -80 °C (-112 °F), sometimes lower in special cases.

And why would any compressed air expert avoid that at all costs? Learn more about the damaging effects of water contamination and how to tackle dew point in compressed air systems in this webinar. What will you learn from this webinar

(Atmospheric dew point).While "pressure dew point" is encountered when measuring the dew point temperature of air at pressures higher than atmospheric pressure. Low PDP means there are small amounts of water vapor in the compressed

logger

We developed a pressure dew point multifunction measuring instrument DS 400 with lots of new advantages specially for moisture measurement resp. dew point/pressure dew point Bubbles occur during varnishing and coating processes How does water get into compressed air?

The dew point is the temperature at which a mixture of air and water vapor saturates. The classic method for determining the dew point is to slowly cool a polished surface until condensation occurs. The temperature of the surface when the first drop appears is considered the dew point.