2. Methods to measure the concrete moisture. Water in concrete is presented in three states: as Temperature, wind speed and environmental relative humidity are variables that must be considered Figure 19 shows how water molecules require higher or lower energy to escape depending of

predicting temperatures throughout mass concrete elements. have been available since the 1920s. no guidelines on how to account for slag cement. measured adiabatic temperature development was used. For. example, the calculated maximum temperature in the.

concrete matures faster at early age. This concept was introduced to the concrete industry as maturity concept in order to predict concrete strength Construction practices of how to control mass concrete temperatures vary. Prescriptive specifications with simplistic methods have been

Temperature is typically measured to make sure the concrete is in compliance with certain specifications that define an allowable temperature range. Typical specifications require the temperature of the concrete during placement to be within a range of 50°F to 90°F (10°C to 32°C)...

COMMAND Center Temperature & Maturity Meters. 1 391 просмотр • 25 мая 2017 г. • The COMMAND Center concrete temperature and maturity system is used to measure and log concrete temperature history, calculate How to Develop a Roast Profile - Coffee Roasting. N3Roaster.

The temperature measurement is typically done to make sure the concrete is in compliance with certain specifications that define a certain allowable Typical specifications require the temperature of the concrete during placement to be within a range of 10°C to 32°C. However, different

What are the temperature limits to avoid damage to concrete during placement, pour, set, curing? This series also describes how to recognize and diagnose various types of foundation failure or Test results show workability, as measured by slump, is greatly affected by casting temperature.

Maintaining appropriate temperatures and temperature ranges within mass concrete is a key to maintaining its durability and longevity. According to ACI 116R, mass concrete is "any volume of concrete with dimensions large enough to require that measures be taken to cope with generation

change effects biden control climate gas university

Home › concrete thermometer › Measuring temperature of Concrete using data logger or Thermocouple. In a civil construction environment, the temperature of concrete during the curing process needs to be measured and recorded to evaluate the process of curing and removal

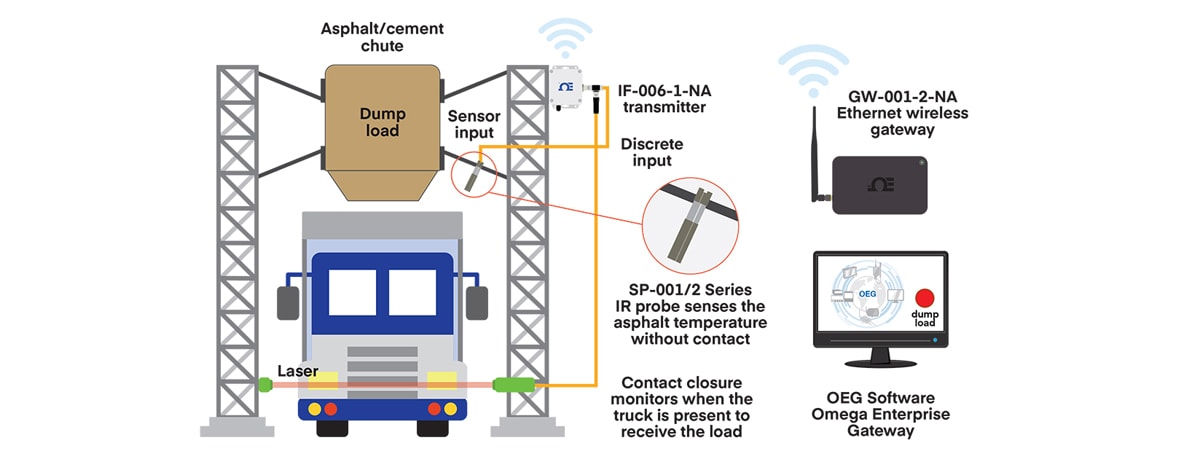

...wireless concrete temperature sensors - we refer to digital devices that can measure and transmit data Most wireless concrete temperature sensors on the market come in the form of individual devices their accuracy is dependent on not just the combination of metals used but also on how

Small, self-powered sensors automatically measure concrete temperature data at predetermined intervals and store data internally. Retrieve data from the sensors with a wireless or wired device. Analyze data with free

Damage to concrete structure can occur if concrete develops to high temperatures in the early age phase. These damages include reduced final The maturity method relies on the measured temperature history of the concrete to estimate strength development during the curing period.

temperature of the concrete to ±1°F throughout a range of 30°-120°F. • Calibrate once a year or whenever there is a • Which type of concrete can this test NOT be used for? • How many layers do we fill the measure in? • • To measure the air content in the mortar (paste) fraction of the concrete.

Having the temperature information will help site engineers figure out how they will protect the concrete from extreme temperatures, and how to Thermometer - Your concrete thermometer must be able to measure from 30°F to 120°F, and needs to accurately measure the temperature of

The pH is measured of a solution; however, concrete is a solid substance. This creates a funda-mental challenge of how to accurately measure the pH of Record each of the three pH readings. 2. Use infrared thermometer to measure surface temperature of concrete to the nearest degree

iiot

Temperature measurement (also known as thermometry) describes the process of measuring a current local temperature for immediate or later evaluation.

Learn how your concrete supplier gets accurate measurements for every concrete project with helpful tips and insight you can use on your home projects! If you took metric measurements, then multiply the length by the width by the depth (L x W x D) to find the volume needed in cubic metres.

How to Calculate the Initial Concrete Temperature. temperature measured at the surface of the concrete in a 24h period shall not exceed: 22oC for sections from 300 to 900 mm in the least dimension 17oC for sections to m in the least dimensions 11oC for sections greater than

Temperature Measuring Device. How deep should the thermometer go into the concrete? min. 3". What should you do after placing the TMD in the concrete? Pat around the edges to ensure no air temperature interfering with the reading.

rose roses block plants plant trees garden grass mother don soil down compost hard mix huge ingrid kaper moist types

How to Measure Concrete Moisture—Common Methods. Before applying a protective coating or other flooring materials to a concrete slab, it is critical to ensure that the moisture level inside the concrete has decreased to acceptable levels. If not, moisture can accumulate below the coating or

Temperature measurements can also be taken in the transporting vehicle or within the forms as long as 3 inches of concrete surround the thermometer. Measure the amount the concrete slumps or settles from the original height of 12 inches to the nearest 1/4 inch and record as the slump in inches.

Measuring concrete temperature during curing requires instrument and high costs. The used concrete temperature prediction methods The measuring began right after specimen concreting and during the curing process. Temperature was recorded until 30 hours after concreting, which

linear feet foot calculate calculator vs measurement per inches inch length much measurements measure inchcalculator measuring fractions cost calculating pound

The increase of concrete temperature results in a decrease of the volume of entrained air. Temperature difference between the upper and lower parts of concrete block caused by the annual variation of the placing temperature of concrete.

Concrete Technology-Concrete Construction-Cold Weather Concreting. How Concrete is Made. Cement & Concrete Applications. Depending on the actual ambient temperature, protection of a concrete placement may require the use of windbreaks, enclosures, or supplementary heat.

The temperature of the concrete affects the way it cures, and the final-strength gain. Fresh Concrete Temperature-Test Apparatus. The temperature testing apparatus includes The thermometer must be able to measure the temperature range of 30°F to 120°F. It must measure

Keywords: batching; conveying; heavyweight concretes; lightweight concretes; materials handling; mixing; placing; preplaced aggregate concrete This guide outlines procedures for achieving good results in measuring and mixing ingredients for concrete, transport-ing it to the site, and placing it.

If you want to measure the temperature of a solid that is not held at a steady state condition - such as what is encountered in everyday life, then you could use This would show how the center of the solid lags behind the surface of the object when the object is subjected to changing surface temperatures.

brick cost installation much does install

Monitoring the concrete temperature can give useful insight about the concrete curing. To be able to control the heating in the concrete, you need to measure and monitor the process. This can be done by using thermocouples - an inexpensive solution and widely available.

How Is Temperature Measured In A Concrete Dam? For this, the temperature should be accurately measured at many points in the structure, in the water and in the air. A sufficient number of sensors should be embedded to get a correct picture of temperature distribution at various points

COMMAND Center temperature sensors automatically collect concrete temperatures at regular intervals during curing. When receiving a delivery of fresh concrete, construction teams typically embed a common thermometer into the concrete to measure its temperature.

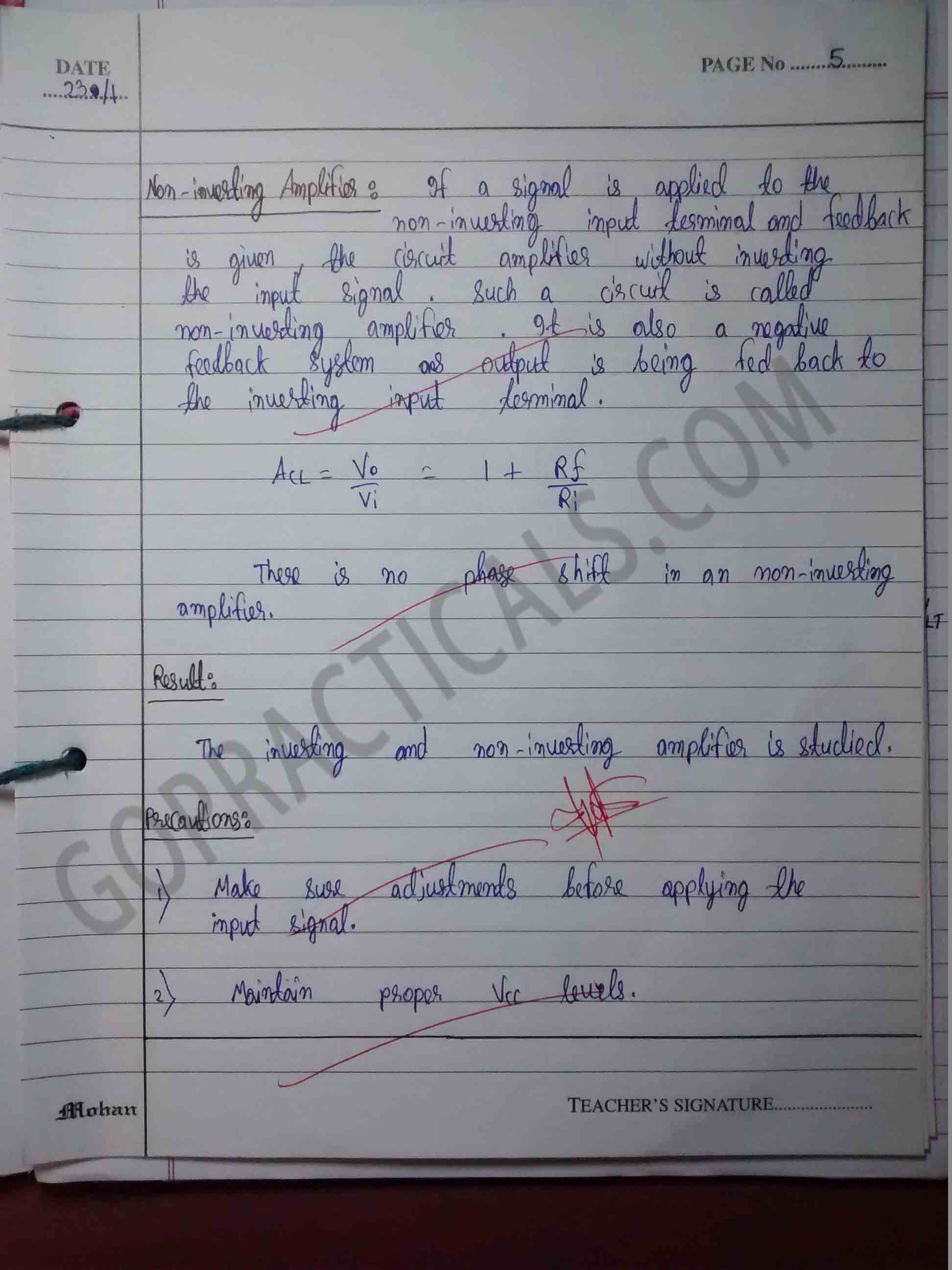

inverting amplifier aic inverter electronics

concrete slump slumping aggregate