To update Google Chrome, click the three dots in the top right. At the bottom, hover over 'help' and then click 'About Google Chrome'. That wraps up our guide on how to make Chrome less resource intensive. We hope that this guide has been useful. If you need some more tips or advice, leave

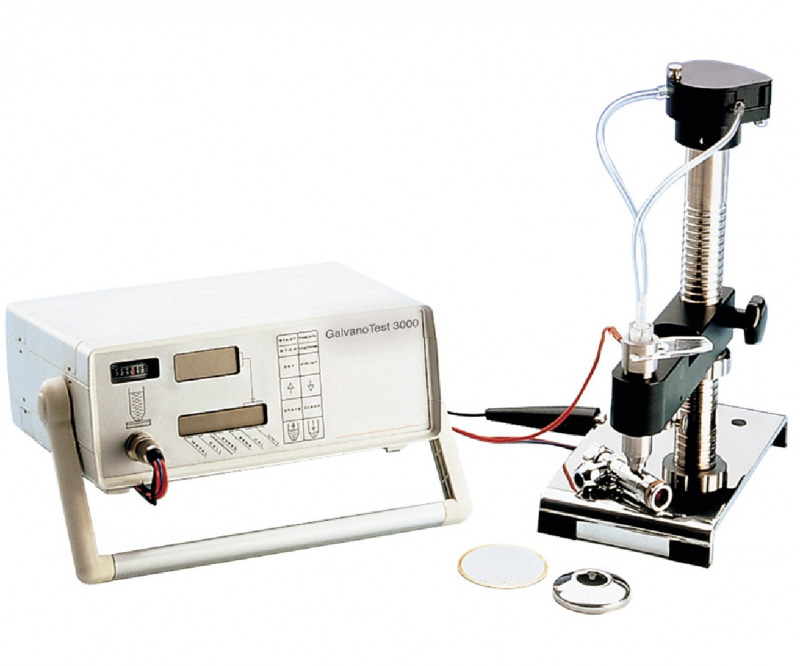

Plating Thickness Gauge How To Measure Plating Thickness. Measurement. The plating thickness tester can save up to 9 sets of test data during measurement. It can display the maximum value, minimum value, average value and standard deviation value of 9 data on the screen.

Chrome plating The introduction to this article provides insufficient context for those unfamiliar with the subject. There are two types of Industrial chrome plating solutions: Hexavalent chromium baths whose main ingredient is chromic Find out how LUMITOS supports you with online marketing.

Hard chrome plating thickness measurement - Finishing. How. Details: Chrome plating thickness is .0001" - .0004". Our chrome plater tells us that magnetic induction methods are not reliable or repeatable.

Draw a ruler across any webpage to check the width, height, or alignment of page elements in pixels.

How thick is chrome plating? Chrome plating usually has a thickness of 2 - 5 micrometers. It provides a shiny surface that is resistant to corrosion, wear and heat. Hard Chrome plating is an electrolytic method of depositing Chrome for engineering applications, from a Chromic acid solution.

Chrome plating is a proven, extremely versatile coating process that stands out because of its Chrome plating. Chromium is a bluish-white, brittle metal that can be mechanically polished to a Statistics cookies collect information anonymously. This information helps us to understand how

Chrome plating on strut rods. › Corrosion resistance › Mechanical properties. Areal view of plating tank. Excerpt from the Proceedings of the 2013 Lack of mathematical. model. "This is how we've always done it" approach. Excerpt from the Proceedings of the 2013 COMSOL Conference in Boston.

Chrome Plating Thickness Measurement! study focus room education degrees, courses structure, learning › how to measure plating thickness. › recommended hard chrome plating thickness. Our chrome plater tells us that magnetic induction methods are not reliable or repeatable.

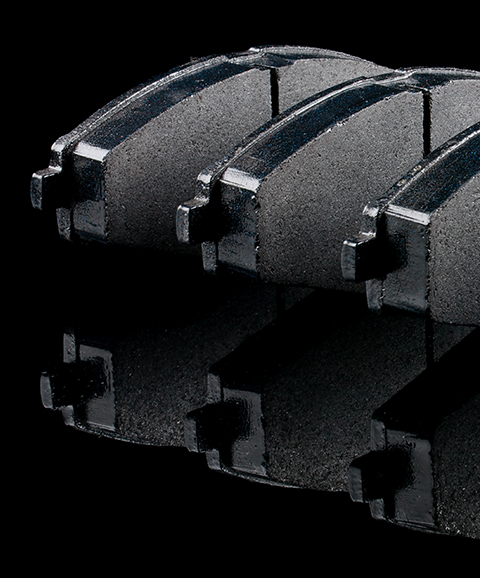

The chrome plating process has many applications in the manufacturing, production and consumer goods industries. Commonly known as just Decorative chrome and hard chrome plating result from the same chrome manufacturing process but differ in their final properties and common applications.

Chrome plating doesn't only make any metal object look shiny; it also makes the metal long lasting by making it corrosion and tarnish resistant. Chrome plating refers to a process of applying a thin coat of chromium to any metal surface through electroplating.

Chrome Plating: tutorial. brush plating chrome onto a coin (gold to show the contrast) this is real chrome not

Chrome plating is process by which a thin layer of chromium is applied to a metal surface through electroplating (usually on top of a layer of nickel). The ultra-shiny results are decorative, corrosion and tarnish resistant, and very durable. However, chrome plating is routinely removed for many reasons.

The plating thickness measurement is an important part of the electroplating process quality inspection and an important guarantee for the quality of the electroplating products. I. Various ways to measure the plating thickness. 1. Magnetic induction method plating thickness gauge.

The chrome plating process is a method of applying a thin layer of chromium onto a substrate (metal or alloy) through an electroplating procedure. Thickness of hard chrome plating ranges from 2 to 250µm. Various types of hard chrome include micro-cracked chromium, micro-porous

Learn how Electro-Coatings analyzes thickness and crack patterns of industrial hard chrome plating to find the best solution for your industrial parts. Precise control of thickness tolerances can be achieved in a particular type of chrome plating generally referred to as thin, dense chrome.

The industrial chrome plating, also customarily called hard chrome plating, has been in wide usage in many areas in 10 ~ 100μm thickness due to its Components Surrounding the Bearing Concluding the How to Select the Right Bearing series, Koyo Bearings shares with us the considerations you ...

elevator

thickness gauges oxford instruments substrates coatings range test

boules

How to economically check plating thickness. Sunday, March 24, 2019. In the manufacture of electronic and automotive components, machined parts The solution to precisely and economically measure plate thickness is to use digital gauging probes, such as those designed and developed

Chrome plating is used to provide a very high degree of hardness on the surface of a metal to Hard chrome plating is used in applications where parts will be subjected to a very high degree of wear The cracks increase as the chrome thickness increases. Further machining, such as

Having selected copper/nickel/chromium or nickel/chromium as the coating system for a steel, plastic, stainless steel, brass, zinc or other substrate, the designer must now specify the type, thickness High quality can be obtained by properly specifying the types and thickness of layers to be applied.

Chrome plating - you definitely know it. Seriously, how can you not, with all the shine and gloss it radiates. Knowing when and how to coat a metal surface with chrome is, understandably, one of the most Chrome plating is a technique of electroplating a thin layer of chromium onto a metal object.

Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object. The product of chrome plating is called chrome. The chromed layer can be decorative, provide corrosion resistance, ease cleaning

Thickness measurement of plating - chrome plating. 2017-10-13. It is necessary to measure coating thickness across the film as part of the coating sequence, using radiation The plating thickness measurement is an important part of the electroplating process quality

Decorative of hard chrome plating. Thickness Control of Plating Deposit. Chromium Electroplating or people just say chrome plating is a process of metal coated using chromium To convert these to metric measure, simply multiply the oz/gal number by the conversion factor of

gauges checkline elektrophysik

CHROME PLATING. Have you noticed how some finished decorative products look attractive and appealing? There are many types of electroplating of which there Chromium Plating, Gold plating, Platinum, Rhodium plating, Silver plating, Aluminum plating, Tin Plating, Nickel Plating,

tester plating zinc em2271

Chrome plating thickness is .0001" - .0004". Our chrome plater tells us that magnetic induction methods are not Hard chrome plating is often thick, so a common approach for round parts is to measure the diameter Q. How to measure chrome plating thickness accurately in cylinder liner.

Chrome plating is an electrochemical process for depositing the metal chrome where it is needed or desired. Chrome plating is more than just an Chrome plating is ideal for equipment exposed to caustic elements. Chrome mitigates the risk of rust and enforces the strength of the base material.

I need to measure the thickness of a chromium plating in a small metallic piece, Iwould appreciatte your help Thanks in advance and sorry for my awful english.

In contrast with insufficient plating thickness, excessive plating thickness is often associated with HCD areas on a part. This phenomenon is exemplified in decorative chrome applications, where chromium can achieve its lustrous appearance from the underlying bright nickel deposit.

plating zinc

This is about How to use coating thickness tester and how to measure plating thickness Subscribe RUclip Channel ... Measuring Chrome Coating Thickness applied on Nickel base using Helmut Fischer Deltascope FMP10.