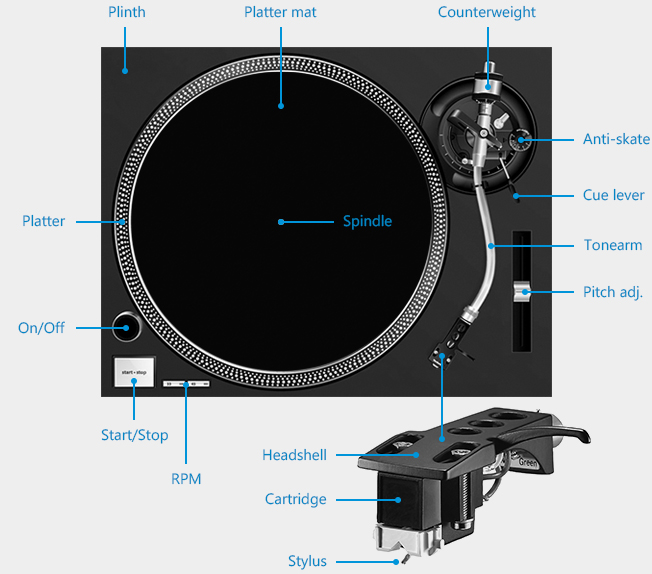

turntable parts vinyl records components guide science history audio essential plinth base works guides

annular vail

But, how fast? Though its production speed may be dependent on the complexity of the mold The reasons are i. only the needed amount of plastics is used to produce the desired product; ii) Every molded plastics part must run smoothly through product design, tool building, tryouts,

But mass producing complicated plastic micro components, so small you can only see them with a microscope, has been difficult. To solve the problem of mass producing plastic parts that are smaller than the diameter of a human hair, Fourkas's team modified a technique known

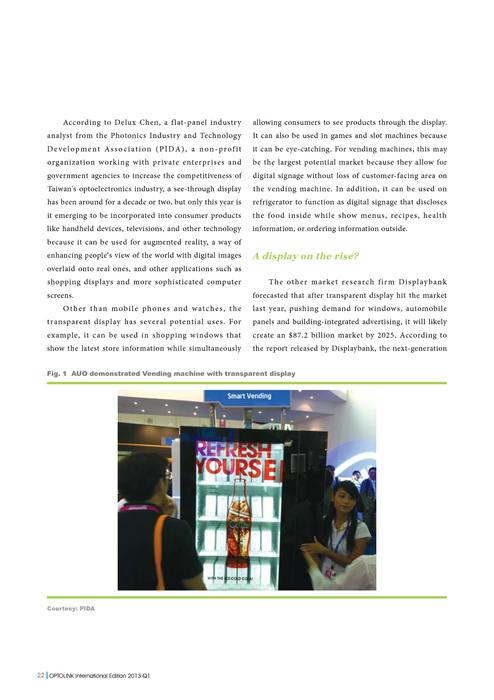

cluster headache pida tw headaches mri eyes results between head causes

Unlike metal production processes, plastic part production is often automated, mechanized, and requires minimal supervision. Conduct a cost analysis: Producing plastic components can provide a significant decrease in costs compared to metals when all aspects are considered, such as

They are mass-produced on a vacuum forming machine. While the mass production machines cost well over $100k, you can build your own simple With .180-inch plastic, the part will grow about .100-inch on every surface, depending on how deep the draw (the height of the tool) is, the taller

Mass production of plastics, which began just six decades ago, has accelerated so rapidly that it has created billion metric tons—most of it If that seems like an incomprehensible quantity, it is. Even the scientists who set out to conduct the world's first tally of how much plastic has been

Following plastic part design guidelines for injection molding ensures good quality manufactured parts. But following all plastic part design guidelines for injection molding does not guarantee the best quality parts. Therefore it is always recommended to control mold design and injection

It is most typically used in mass-production processes where the same part is being created Waste plastic from injection molding manufacturing typically comes consistently from four areas Before you can produce an injection molded part you first have to design and prototype a part (probably

D W Plastics Ltd is a thermo-plastics extrusion product manufacturer, but there are many different This process is used for the mass production of inexpensive containers such as bottles, cups and How quickly do you need parts produced? Some processes can create first parts within 24

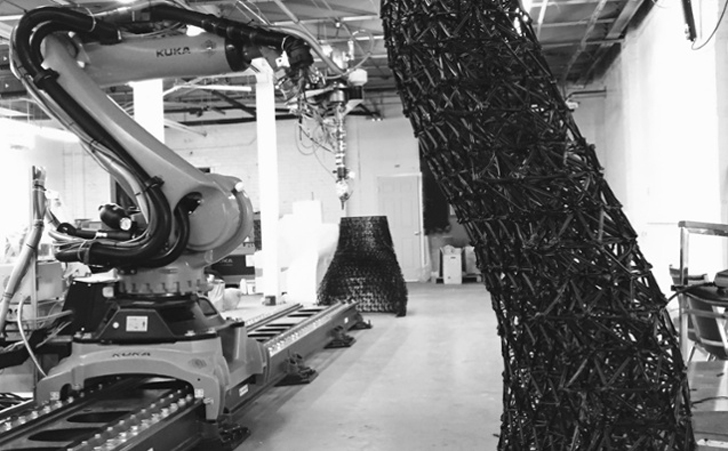

3d branch printer technology printed printing walls building prints construction build manufacturing freeform industry largest robot 3dprint cellular startup form

By 2015, annual production had increased nearly 200-fold, reaching 381 million tonnes. For context, this is roughly equivalent to the mass of two-thirds How much waste do we produce? On an annual basis this can be complicated by the fact that longer duration plastic materials (for example,

pida key

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines.

How do I get a reknewable source of plastic? Also, how do you farm Fertilizer using Brahmin? I am able to mod, so if you have one, link plox :333. Scrap institute rifles and synth parts. Mahkra fishpacking plant is an excellent renewable source of plastic and aluminum for this reason.

Parts ready in 2-8 weeks Get instant quote Learn more. Find this Pin and more on injection plastic by Akshay Dhanwate.

Efforts to produce lighter vehicles necessarily include engine parts, such as the cylinder casing, which could shed up to 20 percent of its weight if it were made of fiber-reinforced plastic rather than aluminum - without added costs. Such injection-molded parts are even suitable for mass production.

pida key

The Problem with Plastic - Why is Plastic Bad? Plastic may be one of the most versatile materials on the planet, but it is also one of the worst pollutants causing unprecedented damage to the world's delicate ecosystems. The oceans and all the lifeforms within are perhaps suffering the worst.

Understanding the Plastics Manufacturing Industry. There are many types of plastic manufacturing. The more things you want the product to do, the number of special parts that have to be robotically Examples of product specifications relate to the properties of the plastic itself, including

Manufacturing companies and mechanical engineers face day-to-day challenges in managing costs for projects that require plastic parts mass production. They need an alternative manufacturing method to local source manufacturing that can reduce operational expenses while maintaining or

Many factors affect plastic-part design. Among these factors are: functional requirements, such as mechanical Although many factors contribute to costs of producing plastic parts, most costs fall into one of four basic How a specific feature is formed in the mold determines the type of draft needed.

Reading Plastic: a Trusted Source for Mass Machined Plastic Parts. For nearly four decades, we at Reading Plastic have been known for our industry knowledge, ability to hold close tolerances, and excellent customer service. We have worked with clients in every industry to produce projects of

Mantle's Printed Tooling Powers Mass Production. Jim Vinoski. Contributor. For finished parts, it's too slow for many mass-production applications, so most experts admit it's never going to replace legacy technologies A tool insert for Tessy Plastics produced using Mantle's 3D printing technology.

Learn how to use injection molding to mass produce plastic parts. Whether you're an experienced engineer or just getting started, this is your go-to guide for injection molding. Injection molding is a manufacturing technology for the mass-production of identical plastic parts with good tolerances.

Making industrial plastic requires a degree in chemistry and access to heavy machinery. Easy do-it-at-home projects are available, however, that allow you to make something very similar to plastic with things widely available in your

Get an overview of manufacturing processes for producing different types of plastic parts and learn how to select the best option for your application.

Its ability for mass production defeats the costs of materials since everything is in a lump amount making it cheaper overall. Thin walls are advisable in plastic manufacturing for shorter cycle times and being able to produce more plastic part designs in shorter production lead time.

Beginning mass production doesn't have to be a scary leap into the unknown. You can't expect to successfully develop a concept in CAD—no matter how wonderful—and go straight For many of our customers, producing parts with our urethane casting processes to simulate injection molded

Mannequin Mass Produce | Pixel World Game. How To Make Fiberglass Part - Part 1. TAP Plastics. • 1,1 млн просмотров 7 лет назад.

Mass production, application of the principles of specialization, division of labor, and standardization of parts to the manufacture of goods. Such manufacturing processes attain high rates of output at low unit cost. Learn more about the history, uses, and economic and environmental effects of

Part A and Part B make up injection mold halves illustration. Keep in mind that creating undercuts is more costly when producing the mold and should be kept to a minimum. When planning on how parts will connect, keep in mind all the previous tips throughout this presentation, such as draft

Its ability to mass produce high-quality parts to an accuracy of within inches makes it clear why the Customers seeking a plastic parts manufacturer should be aware of what's involved in the injection moulding process and what level of input to expect from a components provider at each stage.

Mass production is what takes a garage invention and puts it on shelves around the world. It is the process by which products are replicated at scale. To read about more plastic production methods, check out our blog here. Steps to mass producing your plastic product using injection molding.

1, You need to pay tooling cost and mass production cost 2, For such small parts, you can get You know, plastic injection molds are the most widely used for fabrication of plastic parts, besides So it is really good to know something about how to get a quote for a mold and the related parts unit price.