belt clipper lacing lacer tool views

This Kit discusses how to select the right manufacturing process for metal parts by comparing CNC and Additive Manufacturing (AM) Powder Bed Fusion Binder Jetting Metal Technologies Compared Powder Bed Fusion vs. Binder Jetting CNC vs. Additive Manufacturing How-to get started 3D

manufacturing parts metal mass production

process of melting metal one ultra thin layer at a time also isn’t terribly fast—our instruments may take a few days to build. For many parts, CNC machining remains the most economical choice. For everything else, DMLS may offer a number of advantages, chief among them design flexibility. Lightweighting Parts with Metal 3D Printing

Metal fabrication is the process of turning raw metals into pre-made shapes for assembly use. For example, the panels that comprise the frame of an automobile are made through When people are taught how metal fabrication works, the following processes are usually part of the training program.

galvanized wheatland

13, 2020 · What are some common processes for mass-producing metal parts? Sheet metal: When origami works, it is wonderful - sheet metal molds are quick and cheap to make and the lead time CNC machining: When the part is highly complex in shape, CNC machining may be necessary. This is prohibitively ...

Metal manufacturing is essential for all areas of the economy. Because of their strength, stiffness, and Sheet metal forming is the most cost-effective forming procedure today for manufacturing parts in Watch the video to see how Shane Wighton from the Formlabs engineering team formed a

Metal Additive Manufacturing technology. The range of metal AM technologies is increasing continuously. Many metal Additive Manufacturing principles are based on a welding process. Thus, materials require good weldability to achieve stable fusion processes.

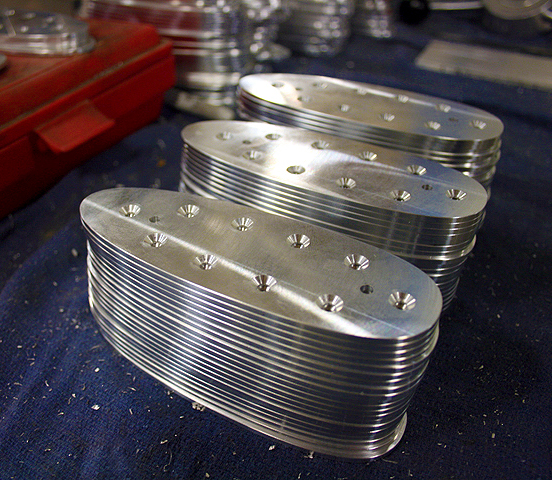

machined finished parts ampco

Sheet metal is the basis of all engineering today. We can see it everywhere - from cars and machinery to house facades and furniture. This includes standard measurements, materials, differences in manufacturing and possible forming methods.

Machining: The Foundation of Metal Manufacturing. Casting and Molding: Adding Volume to Metal Fabrication. 3D Printing: For When Things Get Protolabs' machining service makes parts from two types of aluminum: 6061-T651 and 7075-T651. The T-suffix signifies how the material was

How Powdered Metal Parts are Formed. One of the oldest methods to make PM parts is still used today - in fact, it is used to manufacture 1MT/year of iron-based alloy structural components. These components are made by blending a fine iron metal (typically <180 microns) with additives such

From machining to MIM, metal parts buyers have a wide range of options for addressing their part-production challenges. No fewer than 6 distinct — and commonly used — techniques exist for the manufacture of metal pieces and parts in 2018.

metal parts process deliver results

Every metal known to humankind comes Exploring material selection and manufacturing techniques for metal prototypes and production parts. 3. CNC Machining: The Foundation of Metal Manufacturing. 4. Casting and Molding: Adding Volume to Metal Fabrication. 5. Metal 3D Printing

Injection MoldingSubtractive ManufacturingAdditive ManufacturingStamping (also known as pressing) is the process of placing flat sheet metal, either in blank or coil form, into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes including punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining…See more on Reading Time: 8 mins

Custom Sheet Metal Parts & Precision Components Built in 2-3 Days. "I love how your engineers communicated with me before the parts went into fabrication and warned me when I cannot believe how quickly they were manufactured and shipped. The delivery was due for next Tuesday, and

When carrying out orders for metal parts at our production facilities, we often receive requests from our customers to manufacture parts through other manufacturing technologies We understand that quality as well as meeting production and supply deadlines are very important for our customers,

Engineers designing sheet-metal parts should understand the importance of bend relief and how it helps avoid torn metal and that features like beads and flanges serve specific purposes. They reduce the spring-back effect and add stiffness to the final part or product.

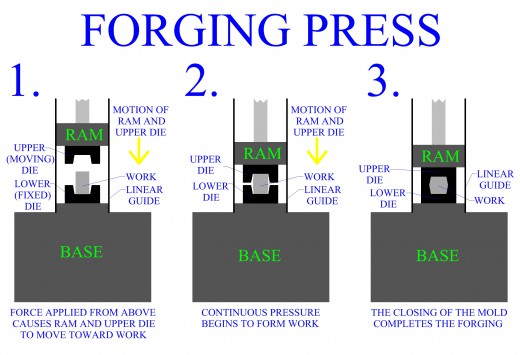

forging press process presses hydraulic mechanical types pressing manufacturing hammer machine die cold drop screw explained figure

Metal additive manufacturing, also known as metal 3D printing, is a technology that produces three-dimensional parts layer-by-layer from a powdered metal material Metal Additive Manufacturing Services. DMLS Parts In As Soon As 3 Days. Complex Metal Parts From A Variety of Alloys.

metal manufacturing parts assembly american scale

The metal is extruded through the hole to form the shape. Extrusion can be used to manufacture important parts of a car's drive train or the anchors that hold seatbelts in place. On the next page we'll look at how modern metal forming technologies are moving auto manufacturing into the future.

gardner denver compressor air pump gas industrial cylinder

"Stereolithography for Metals" Produces Detailed Parts. Lithography-based Metal Manufacturing (LMM), a new technique developed by Incus uses Similar to binder jetting, Lithography-Based Metal Manufacturing is suitable for small, finely detailed parts such as dental brackets, hinges for

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships,

metal parts fabrication manufacturing manufacturer

30, 2018 · Powder Metallurgy (PM)/ Press-And-Sinter: Low Complexity, High Volume. PM, also known as press-and-sinter, is a process by which metal powders are compacted with heat or pressure to form a green part, which is then bulk sintered in a furnace. The advantages of this technique are fairly simple: it’s Reading Time: 6 mins

The aerospace industry is a pioneering sector for additive manufacturing and is paving the way to serial production. Now, the ready are evaluating beyond the part and considering how metal additive will benefit the entire system—from part cost to supply chain to potential new market opportunities.

Today's metal 3D printers are the mainframe computers of manufacturing. They are large, slow, and expensive ($500k -1M). Markforged's Atomic Diffusion Additive Manufacturing (ADAM) process for printing metal unlocks a new era of metal parts production.

Sheet Metal Fabrication is an economical manufacturing solution for low to high volume steel and aluminium parts. Get It Made offers sheet metal parts with no Minimum Order Quantity (MOQ), providing you with the flexibility to order the parts you need, when you need them.

roller metal sheet slip roll manual bending stand industrial

In metal parts manufacturing, as well as many other industries, ISO 9000 guidelines are used in establishing, documenting, and supporting quality control Follow these tips on how to choose a vendor for cut off metal parts and get the results you want for your precision manufacturing needs.

WAAM is particularly suited to manufacturing large-scale metal parts. Parts produced with WAAM are particularly notable for their high density and strong mechanical properties, which are comparable to parts manufactured with traditional manufacturing methods.

I was absolutely amazed at how easy it was to do, and how well it works. I can't believe that this Do not attempt to pour the metal back out of the mold! Once the metal is poured, you're done. The ability to manufacture metal parts at home puts you on the same playing field as companies

how B & B Manufacturing creates a Sheet metal part from start to finish!B and B Manufacturing is a full service sheet metal shop, in Forest Hill,

Sheet Metal fabrication is a subtractive manufacturing process where parts are created by removing material from sheets. General Cost-Saving Machining Tips. Download the FREE guide to learn how to: Design for low-cost manufacturing. Select the most suitable materials and finishes.

22, 2017 · In sheet-metal fabrication, parts are formed from metal sheets by punching, cutting, stamping, and bending. 3D CAD files are created using a host of different CAD packages and then converted into ...Author: Greg PaulsenEstimated Reading Time: 5 mins

22, 2019 · In the manufacture of metal parts, which in turn are used to make countless other products, the purpose of quality control (QC) is to not only prevent defects, but also ensure that the parts are made to design specifications and will function properly. A good QC program also helps to keep manufacturing on time and on Reading Time: 9 mins

Metal parts fabrication has become an integral part of the manufacturing process. From paper holding clips to airplane parts, it is widely used in creating parts for various industries. I What's Metal Fabrication? II How to Manufacture Metal Parts. III Surface Finish Options for Metal Parts.

casting gravity die aluminium cast services castings machining caster jobs leeds polish workers

See how B & B Manufacturing creates a Sheet metal part from start to finish! B and B Manufacturing is a full service sheet metal ... Wire Arc Additive Manufacturing: Enabling 10-Meter Metal Parts Filomeno Martina, WAAMMat Program Manager Welding ...

Metal Part Manufacturability. You want to control your costs and the best way to do this is to make the bracket easy to manufacture and selecting the Now let's dive into how the design of your metal part will affect manufacturing costs: Flat Blanks Most fabricators these days have the ability with lasers

Manufacturing Metal 3D Printing Metal Additive Manufacturing Small Metal Parts Stainless Steel Parts. There are hundreds of methods to make metal parts. The list of technologies and techniques can be overwhelming.

Today, metal Additive Manufactured parts are designed for a large number of industry sectors (especially This article discusses how to design SLS 3D printed parts including technical design specifications, materials, limitations and an introduction into the post-processing options available.

to view0:57For large-volume production, machined parts are often transitioned to casting or molding processes. Metal injection molding, or MIM, is the process whereby metal powders such as nickel steel, 316 stainless, 17-4 PH or chrome-moly are mixed with a binder composed of wax and …

parts metal manufacturing surface

See how B & B Manufacturing creates a Sheet metal part from start to finish!B and B Manufacturing is a full service sheet metal shop, in Forest

Various manufacturing methods on sheet metals can be classified as follows By interchangeability it is meant that the parts manufactured anywhere can be assembled without rework. We also use third-party cookies that help us analyze and understand how you use this website.

foundry heat ensuring phases manufacture critical operations highest customers industrial even metal parts