What is a SIP-panel and how fast to build a house of these items? The technology is so simple that you can just a week to collect the building. Description of material. SIP panels. They are the major building blocks. The calculation is made on the project at home. Floor used thick plates, medium

solar panels cabin yourself diy installing buildmyowncabin

frp panels panel fiber honeycomb plywood core tech fiberglass structural reinforced fibertech plastics half variety wide

This measure guides describes how to install structural insulated panels to block excessive heat loss and gain though structural framing. Construct exterior walls with structural insulated panels (SIPs) to provide an air-tight wall with consistent insulation and very little thermal bridging.

Q: In India SIP are made using steel plates since OSB is not readily available. Which skin material is preferred & why? PU is rapidly replacing EPS as core material. How long have SIP panels been used in residential construction? As an architect, I have not used SIP panels over the years.

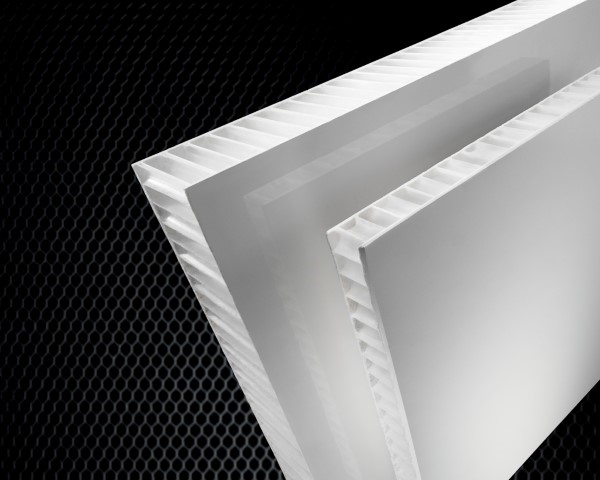

SIPs stands for 'structural insulated panels'. They are made out of two pieces of insulation that are expertly fixed together on each side to two OSB strand board skins. These can then be cut to size, depending on how big or small you might need them. It doesn't matter what type of walls you will

Details: Making Structural Insulating Panels (SIP) There is a little more to SIPs than a sandwich of wood and foam. A manufacturing method is not difficult to come up with as you have discovered. How to Design with SIP Panels - Duratherm Building Systems. Convert. Details: Drag, copy or

ceiling suspended cloud ceilings panels wood acoustical panel floating acoustic systems clouds wooden plywood cool beam hanging patented sandwich honeycomb

Furthermore, what is SIP made of? Materials. SIPs are most commonly made of OSB panels sandwiched around a foam core made of expanded polystyrene (EPS), extruded polystyrene (XPS) or rigid Building with SIPs will save you time, money and labor. How long will sip panels last? 60 years.

› Get more: Building sips panels diyDetail Install. DIY SIP Panels, SIP kits, SIP building systems - ez SIPS. Install. Details: DIY SIP Panels Make Wiring & Plumbing A Snap! If you've ever worked with SIP kits, you'll know that there's a fair amount of drilling and fishing through

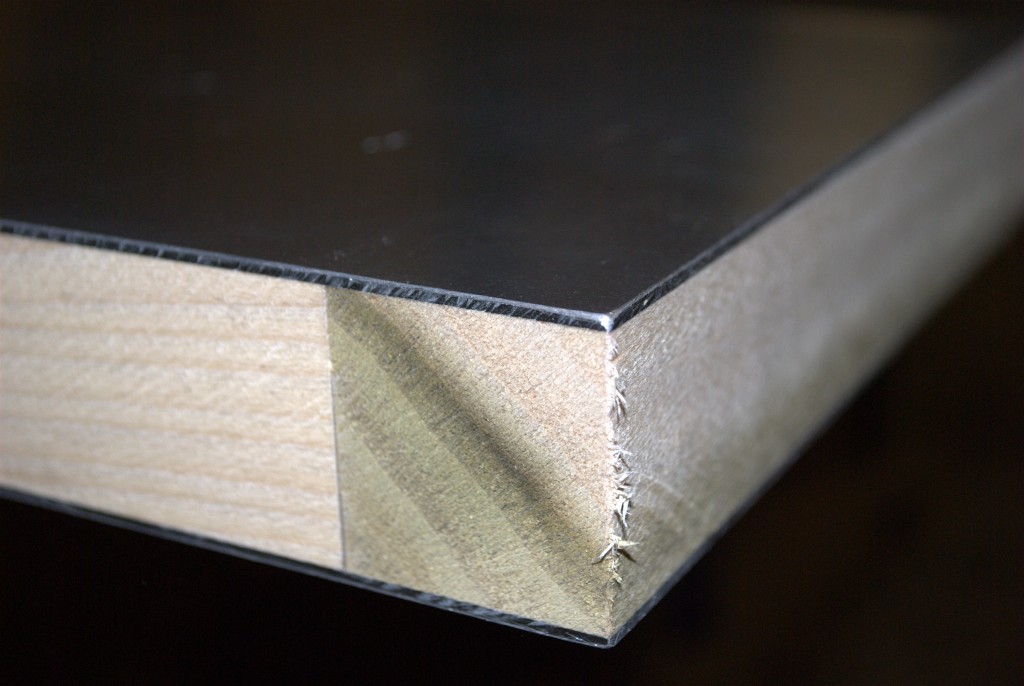

RAYCORE SIP roof panels and wall panels combine three labor tasks into one smart panel system. This system utilizes conventional proven building materials: premium Douglas fir members, state-of-the-art high R-value closed cell polyurethane foam, and a foil radiant vapor barrier.

Structural insulated panels (SIPs) have been around since the 1930s, when they were invented by The Evoke Quadrant Model Home by Quadrant Homes shows how SIPs and other energy saving SIP Panel House by Alejandro Soffia. Waste: Since structural insulated panels are fabricated

Restricted Replacement Panels: SIP Panel manufacturers require the entire building be designed and every panel pre made and pre cut before sending Now, using IADDIC, the raw material to make the foam core takes 1/20th to 1/40 of the space. Unheard of savings because the structural foam core is

A structural insulated panel, or structural insulating panel, (SIP), is a form of sandwich panel used in the construction industry. SIP is a sandwich structured composite, consisting of an insulating layer of rigid core sandwiched between two layers of structural board, used as a building material.

SIP panels are made from environmentally friendly materials, 95% which are made up of solid timber and oriented strand boards. Extruded polystyrene foam acts as a heat insulator inside them, which has higher strength rates, durability and fire safety compared to foam. SIP technology in Russian conditions.

Has anyone here made their own stress skin panels? Has anyone here made their own stress skin panels? I've just done a microgoogle and it appears you could glue a sheet of eps between osb, slip it into a vacuum bag and have yourself a SIP.

Factory-made SIPs panels will be more accurate than on-site cut timber frames, and this helps to limit gaps in construction. Designing with Structural Insulated Panels in Mind. A SIPs designer will be armed with the right info about how to build a SIPs home and be able to design to the capabilities

SIP panel home kits or Structural Insulated Panels are the next step up from timber frame construction. Like timber frame construction the SIP forms the inner leaf of the main external walls of your home. With the outer leaf being made up of brick, block or cladding etc.

Has anyone made or considered making their own SIPs? I have a large amount of 2" polyisocyanurate foam and I'm attempting to research if manufacturing one's own SIPs is practical. I have a rough design for a homemade press (that can be

Moreover, the rejection of SIP panels in favor of classical frame technology in the construction of roof and ceilings is reasonable and economical. Sometimes they make ventilated facades from special decorative panels or even exclusive designs from clinker tiles or clinker bricks.

1. SIPs made of 623x2500x166 mm oriented strand boards with foam polystyrene insulation. 2. 140х46 mm chamber drying sized timber. 3. Fasteners for assembly, foam, assembly instructions. Option 2 is not available yet. 1. Three-layer sandwich panel with Isover insulation, the bottom layer is

Due to SIP panels being pre-manufactured and the ease at which they can be erected, build times are drastically reduced over traditional SIP Panels are pre-manufactured to your own requirements. This saves both builders and architects a lot of In turn, this can make your build projects more profitable.

aluminum panel wood corner panels insulation insulated composite metal sing frame close exposed extreme door value doors foam rigid core

wood panels stave flat doors any sliding grain door block lightweight insulated butcher sing types cedar solid strong planks architectural

SIP panels make housing an affordable project for low-income residents. Families that face the low-income scale spend as much as 19% of their earnings on energy costs. Multifamily or single unit housing projects can reduce their energy costs drastically when the structures are built utilizing SIPs.

Steve Maxwell explains how structural insulated panels (SIPs) create structures that use roughly half the energy of similar, code-built

foundation sips build

The Session Initiation Protocol (SIP) is a communications protocol for signaling and controlling Learn how TCP helps SIP in initiating session and to turn in TCP mode for package sending. How to call it from pjsip, and how to make it compile in Visual Studio for Windows Phone 8. I also learn

panels walk cooler insulation polystyrene refrigeration freezer insulated panel foam styrene floor commercial cold installation sandwich freezers guide resins copolymers

Building with Structural Insulated Panels (SIPs) was first developed in the 1930s, as an alternative home-building technique. Yet it is hardly known by the How much less depends a lot on the specific design of the home. Because of the manufacturing techniques used in making SIP homes, a

Structural insulated panels (SIPs) are a high-performance building system for residential and light SIP panels are the easiest method to reach standards for Air Infiltration, R-Values and Continuous SIPs give you the power to show just how much you care about your customers and the environment.

Making Structural Insulating Panels (SIP) There is a little more to SIPs than a sandwich of wood and foam. A manufacturing method is not difficult DIY SIP panels that are ½ THE COST of factory SIPs. Think of it: all the benefits of SIPs…but $ to $ per square foot of wall instead of $ to $!

SIP panels are made from environmentally friendly materials, 95% which are made up of solid timber and oriented strand boards. Extruded polystyrene foam acts as a heat insulator inside them, which has higher strength rates, durability and fire safety compared to foam. SIP technology in Russian conditions.

Sip House Sips Panels Structural Insulated Panels Panel Systems Prefab Building Materials House Plans Backyard Construction. SIPs (structural insulated panels) are pre-insulated, storey-height panels that can form part of a building or whole buildings. How to Transform your Wall in ONE DAY!

Details: Making Structural Insulating Panels (SIP) There is a little more to SIPs than a sandwich of wood and foam. A manufacturing method is not difficult to Correspondingly, can you make your own SIP panels? EZ SIPS Build-In-Place Structural Insulated Panels are changing the way homes are built.

How effective are SIPs for thermal insulation? Because the effectiveness of SIPs varies according to the inner foam filling, the types of panels While structural insulated panels have been on the market for some time in the US and Europe, they have only recently begun to make headway here in Australia.

panels sips insulated structural hoods robin bay roofing building cladding

space creative panels insulated structural sefton

Details: Making Structural Insulating Panels (SIP) There is a little more to SIPs than a sandwich of wood and foam. A manufacturing method is not difficult to come up with as you have discovered. Making is reliable and usable is a much bigger challenge. From a practical standpoint, you will