Lightweight concrete, also known as EPScrete (expanded polystyrene concrete), is a material widely used in the building of environmentally "green" homes. The substance is often made using small styrofoam balls as a lightweight aggregate instead of the crushed stone that is used in

To make cellular lightweight concrete mix water with dry mix (cement and limestone compound) add aerated agent and pour the ... For more details visit company website Foamed concrete, also called cellular light weight concrete is ...

How lightweight concrete are made and what are the components of light weight concrete? Lightweight concrete can be made in different ways, either by creating numerous intersectional joint void or by modifying the cementing agent with numerous pores giving cellular structure or by

Since we want to produce lightweight concrete blocks, we will use as little sand as possible. We recommend 22 liters of sand for the lightest mixture. When answering the question of how to make lightweight blocks, we mentioned before that you should act according to the needs of the project.

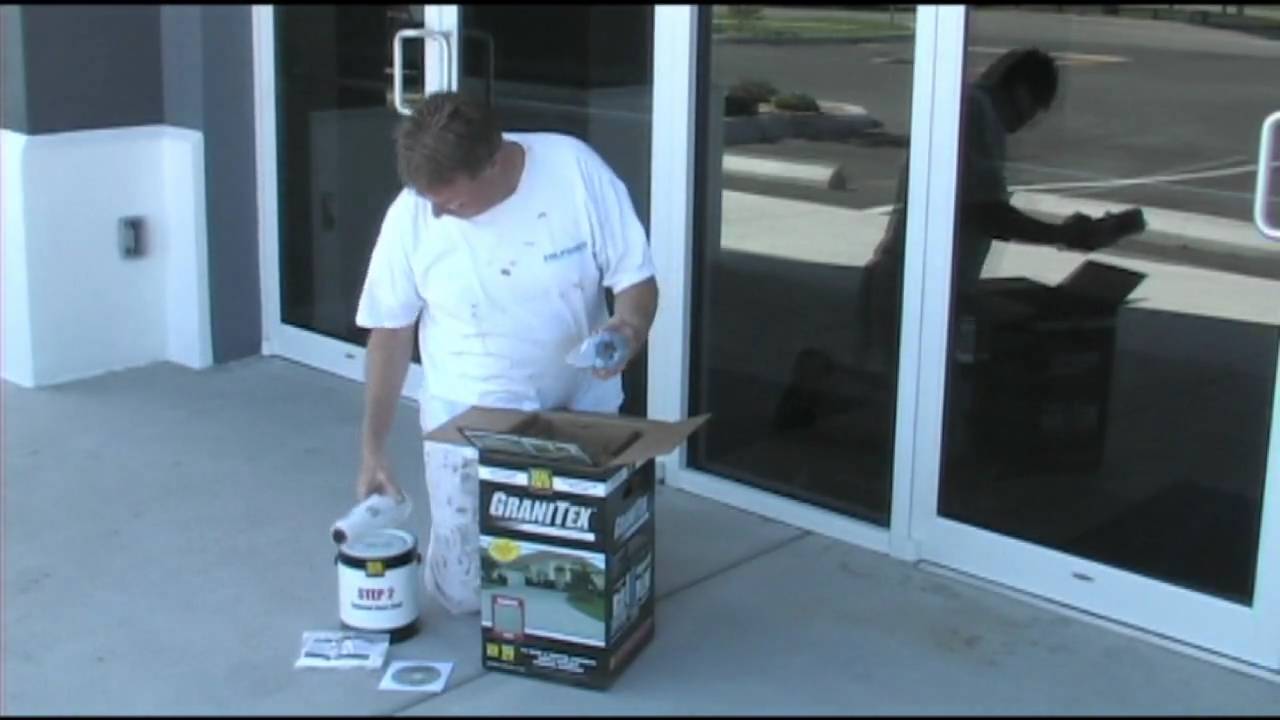

outdoor concrete flooring coating tough weatherproof

Lightweight concrete is one type of concrete made with lightweight coarse aggregates such as shale, clay, or slate, which give it its characteristic Structural lightweight concrete has a unit weight of around 1440 to 1840 kg/m³ which is equal to 90 to 115 lb / ft³ . As we know that Normal

How to Make Lightweight Concrete Using Styrofoam. Place 5 gallons of water into the concrete mixer. Add half a 94 lb. Lightweight concrete mixture is made with a lightweight coarse aggregate and sometimes a portion or entire fine aggregates may be lightweight instead of normal aggregates.

masonry Hollow light weight blocks are manufactured with the lowest concrete density of 1100 Kg/m3 density and the block density at 963 Kg/m3 to 688 Kg/m3. At Emcon, Hollow lightweight blocks are available with a face dimensions of 400 x 200 mm (L x H) and 390 x 190, with varying thickness of 100, 150, 200, 250 and 300 mm.

I made a lightweight concrete table by using self-leveling concrete mix typically used for floor resurfacing to apply a 1/4" coat of concrete over a

Make lightweight concrete garden panels from aircrete. This is PART , showing options to make your lightweight garden boxes from Air Crete. You can build these forms and precast your own 48″, 36″, or 24″ reinforced lightweight concrete panels that link together to make long lasting and

concrete interior panels french firm panbeton haussmann minimal introduces innovative residential

Lightweight concrete mixture is made with a lightweight coarse aggregate and sometimes a portion or entire fine aggregates may be lightweight instead of Lightweight aggregates used in structural lightweight concrete are typically expanded shale, clay or slate materials that have been fired in

concrete core test strength compressive cores extraction ndt civil engineering

Although lightweight concrete could be implemented relatively easily in post-war building practice, the manufacturers nevertheless needed to convince clients The firm offered bricklayers technical training by an expert at the construction yard, to show them how to use Ytong blocks; invited the

How. Details: That being said, lightweight concrete does make an excellent material for planters as it is easier to move around and does not need to be as strong simply to hold in dirt. › Get more: Diy light concrete plantersShow All. Concrete Planters DIY - Large Scale and Easy to Make Curbly. How.

Q: How do they make the small, lightweight porous bricks in Mexico that are used to build vaulted roofs? I can get low-fired clay bricks, but they are not porous like the A: (Kelly) It is possible to make lightweight concrete using Styrofoam as aggregate, and this has many possible uses, especially

How to Make Lightweight Fiber Cement | Hunker. Lightweight cement is a cement mixture using lightweight aggregates such as Styrofoam beads or pumice stones as a replacement for heavier gravel aggregate. The replacement material is applicable using the same methods as traditional

Lightweight concrete is a special type of concrete which weighs lighter than conventional or normal concrete. Density of light weight concrete is conventionally low. Generally 300 kg/m³ to 2200 kg/m³ and thus normal concrete has density between 2200 kg/m³ to 2600 kg/m³.

03, 2020 · Concrete patios with minor damage, but in otherwise good condition, can be transformed with concrete resurfacing. Instead of starting over with a new patio, you can upgrade its appearance and strength with a cement-based overlay. Find patio contractors near me. Your resurfaced concrete patio can be stamped, stained, or stenciled and have color ...

of concrete block: 'Dense', 'Lightweight', 'Aerated' Dense aggregate block. In use from the 1940s onwards, dense aggregate blocks are very much the work-horse of the construction industry. Their distinctive properties of durability and strength make them an ideal and cost-effect solution for all types of load-bearing walls.

concrete granitex coating floor lowe patio garage flooring deck applying stone decorative diy wood broken

concrete placers pouring projects

05, 2022 · The main purpose of this study was to investigate the mix design and performance of fiber-reinforced pervious concrete using lightweight coarse aggregates instead of ordinary coarse aggregates. There were two main stages in the relevant testing work. First, the properties of the matrix were tested with a rheological test and then different amounts of lightweight …

that have a density lesser than 1920kg/m 3 will be categorized as lightweight concrete. The use of lightweight aggregates in concrete design will give us lightweight aggregates. Aggregates are the important element that contributes to the density of the concrete. The examples of light weight aggregates are the pumice, perlites, and scoria.

light-weight concrete density is less because lightweight coarse aggregates and sometimes lightweight fine aggregates are used, which make the concrete weigh less. The lightweight aggregates used are usually expanded shale, clay, or slate materials that have been fired in a rotary kiln to give them a porous structure, similar to volcanic rock.

Lightweight concrete blocks are made by adjusting the ratio of the concrete mix with a lightweight aggregate, like Perlite. However, for most outdoor projects, you want to make sure you use more of a medium mix that will be able to withstand the elements.

How lightweight, and what strength are you looking for? 1. I poured some concrete steps 2 days ago and I want to fill in some honeycomb and smooth out the faces and My question is: Would Type S mortar be OK to put over the concrete treads/risers as a top coat to make

I made a lightweight concrete table by using self-leveling concrete mix typically used for floor resurfacing to apply a 1/4" coat of ... To make cellular lightweight concrete mix water with dry mix (cement and limestone compound) add aerated agent and pour the ...

lightweight concrete which can be sawed or nailed, also for its insulating properties. Concrete is prepared by mixing cement, water, and aggregate together to make a workable paste. Some pores will remain no matter how well the concrete has been compacted.

To make this concrete, combine 8 parts cement, sand and lightweight aggregate with 5 parts water. That being said, lightweight concrete does make an excellent material for planters as it is easier to move around and does not need to be as strong simply to hold in dirt.

insulated concrete panels panel lightweight block construction building form icf sip houses build forms walls apex insulating structural using systems

Grab the best projects on cellular lightweight concrete and how to make it. Learn from experienced mentors and start your project now. Concrete is a foremost important material in the construction industry due to its vast applications. With the recent development in concrete technology, new

How to make a concrete counter top using Rapid Set Mortar Mix. In this video I will show you the quickest and easiest way to make ... Non autoclaved lightweight aerated concrete is a type of lightweight concrete which is used to produce blocks and replace bricks.

Check out how to craft and make with concrete, tips and tricks for concrete crafting and information about various concrete mixes, how to finish. For many the idea of making concrete brings visions of huge metal mixers, shovels and mess. Let me show you some of my Tips and Tricks for

Concrete artisan Buddy Rhodes demonstrates his unique process for building a light but strong vanity counter with an integral sink. Buddy was trained as a potter, but influenced by his builder father, he soon found himself working with concrete, a material that's similar to clay that doesn't need a kiln.

concrete is a building material used as a floor underlayment used in wood-frame and concrete construction for fire ratings, sound reduction, radiant heating, and floor leveling. It is a mixture of gypsum plaster, Portland cement, and sand. The brand name Gyp-Crete, a Maxxon Corporation trademark, has come into general use as a term for gypsum concrete by …

concrete, also known as Lightweight Cellular Concrete (LCC), Low Density Cellular Concrete (LDCC), and other terms is defined as a cement-based slurry, with a minimum of 20% (per volume) foam entrained into the plastic mortar. As mostly no coarse aggregate is used for production of foam concrete the correct term would be called mortar instead of concrete; it …

The term "lightweight concrete" which is preferred by the American Concrete Institute (ACI) will be used rather than the more scientifically correct ACI Committee 213 "Lightweight Aggregates and Lightweight Concrete" defines "lightweight concrete" as being concrete made with

building wood fires frame apartment state construction concrete magazine

Concrete is the basic need for any construction, whether it is an indoor project or a mega project; concrete is manifold. Sometimes, we tend to prepare ourselves for the regular use of concrete in the Today we are going to show you some techniques on how to make a lightweight concrete mix.

concrete suppliers to use carbon sequestration/CO 2 injection methods. Specify hard, clean, and strong aggregates. Weak and/or lightweight aggregates often require the addition of more cement to achieve the necessary mix strength.

concrete planter planters molds mold put stone diy rock smooth weight onehundreddollarsamonth rough

Foam concrete, also known as foamed concrete, or 'foamcrete', is a versatile cement based and porous lightweight building material that can be used for a wide range of building applications around your home. "How To Make Lightweight Concrete Blocks."

How do you make lightweight concrete? The short answer is you take the heavy stuff out of the concrete mix, which would normally be the aggregates sand and gravel, and replace them with a different aggregate that weighs a lot less. This is a pretty dramatic oversimplification since

, lightweight concrete products meant to be seen, touched and loved High-design, lightweight concrete fire pits and cladding. 100% Concrete. 60% lighter. Industry-leading 5-year warranty. Modern, lightweight concrete products meant to be seen, touched and loved High-design, lightweight concrete fire pits and cladding.

concrete panel double sided gang

We make lightweight concrete by adding materials that have specific gravity (SG) less than that of water. It is s a little difficult since you will need to add cement as a binder and this has a SG of We manufacture an engineered concrete additive that has a SG of

How to make concrete planters lightweight and durable? Disadvantages of Lightweight Concrete (LWC). Because of its weightlessness, few practitioners may tend to have the tendency to think like it may not possess the strength as conventional concrete.

· Lightweight Concrete Planters. ... Learn how to make a planter that fits over a picnic table umbrella from funky old Jell-O molds found at garage sales and thrift stores. Because quantity of new How To Make Lightweight Concrete contents are launched instability, so we will update ones regularly.