Sand casting is a casting process by which sand is used to create a mold, after which liquid metal is poured into this mold to create a part. It is difficult to grasp how many different technologies use sand casting. Its versatility as a casting process makes it ideal for almost any complex part,

I'm planning on doing my first sand cast to make a (70cm) bronze sword. Will I just be better off making my own homemade casting sand? I know there are recipes using play sand and clay-based cat litter but I have no idea where to start or what my best or cheapest option is.

The sand casting process is one of the oldest casting methods and has been used for aluminium alloys since they became popular at the turn of the 20th The Cosworth process is a precision sand casting process. It was developed in 1978 initially for manufacturing aluminium alloy castings to

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via

casting is the most popular casting process employed in industry because of its great geometric freedom capability and for its cost effectiveness. In this article, we provide design rules for optimal sand casting performance.

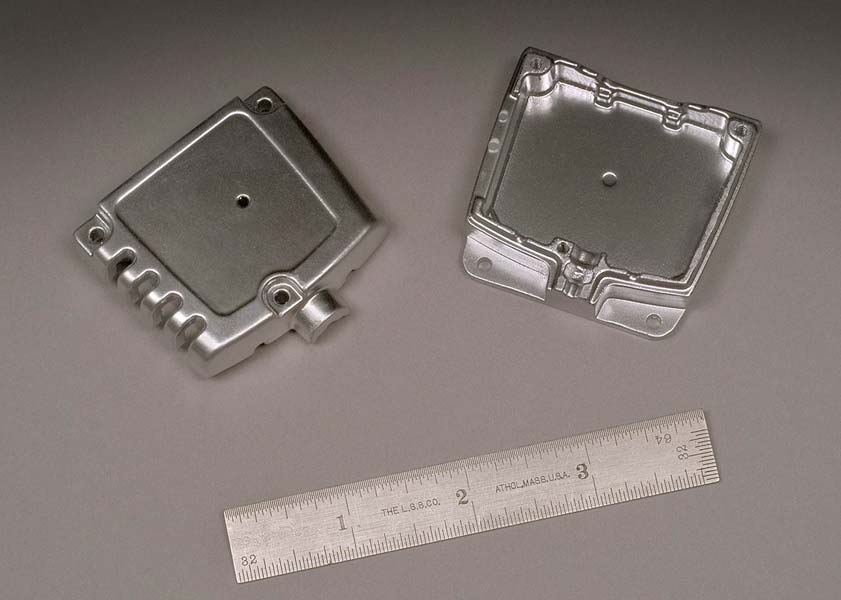

casting involves the pouring of molten metal into a cavity-shaped sand mould where it solidifies (Fig. ).The mould is made of sand particles held together with an inorganic binding agent. After the metal has cooled to room temperature, the sand mould is …

2. How does sand casting work? Sand retains its shape when exposed to high temperatures, which makes it desirable in metal casting since it can withstand the high temperatures necessary to melt alloys. Molds composed of sand-based materials are also easy to break away without damaging

Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must be destroyed in order to remove the part, called the casting, sand casting typically has a low production rate.

(metalworking)Shell molding is similar to sand casting, but the molding cavity is formed by a hardened "shell" of sand instead of a flask filled with sand. The sand used is finer than sand casting sand and is mixed with a resin so that it can be heated by the pattern and hardened into a shell around the pattern. Because of the resin and finer sand, it gives a much finer surface finish.

Green sand formula - how to make molding sand To make green sand or like it also called molding sand (foundry sand) we need How To Do Aluminum Casting Using Green Sand in The Backyard Foundry Using A Plaster of Paris Pattern, A Simple Flask

DIY Sand-Cast Birdbath: Customize your own birdbath using any large leaf, sand and concrete mix and some paint to really make it your own. Sand-casting tips. When it comes to concrete, even though its more expensive, I like Quickcrete® Vinyl Patcher.

I need to make some casting sand, I can get bags of bentonite powder no problems but what sort of sand do I need. Casting Sand Recipe. Thread starter ShedBoy. Start date Jul 18, 2011. How much?

Advantages of sand casting. Low cost of mold materials and equipment. Large casting dimensions may be obtained. Wide variety of metals and alloys The typical mold for a sand casting is shown in the picture: The set of channels through which a molten metal flows to the mold cavity is called

- high quality suppliers of pressure die casting, gravity die casting & sand casting products in the UK and Europe. Quality service and short lead times. Contact us now for more information.

In sand casting, sand is used to define the cavity inside a mold. The first step in sand casting is patternmaking. The pattern is a replica of the exterior of the casting with dimensional allocation for shrinkage and finishing.

common Sand make mould or Pattern out. and ouring into Melten metal liquid into mould or pattern. after cool down, take the part out. Low cost Casting molds the Mould or pattern most is square one. it is simple with low cost.

casting is a process that utilizes non-reusable sand molds to form metal castings. On one hand, casting is a deceptively simple manufacturing process: anyone who has formed castles at the beach knows sand can be used to make detailed shapes.

sand casting jewelry

sand casting greensand homemade cast metal diy projects own

graphite casting molds mold aluminum parts castings permanent alloy zinc

sand foundry vs

Flask making for sand casting - simple DIY - msfn. DIY GREEN SAND FOR CASTING - CHEAP, SIMPLE and FAST - MSFN. How I Built My Aluminum Foundry Furnace For Melting Metal - MSFN.

bullet machine casting cast mark

How. Details: Sand casting is a process that utilizes non-reusable sand molds to form metal castings. On one hand, casting is a deceptively simple How. Details: Sand casting capacity when your have monumental bronze or aluminum sculpture to make. Sand casting can shorten the mold

molds are advantageous on making intricate and heavy mass casting plus low molding cost. To make sand casting molds for metal casting, whether at the foundry or at home, the molding process must be done in a well-ventilated area to …

carbonate calcium metal powder parting casting bag 5kg 3kg bentonite freight kit recommend question ask greensand

aten archaeologists

Im still getting into the whole casting stuff a bit - but figured, that so far the plaster-type stuff I use is quite troublesome - dont know if I get the mixing all wrong or what, but it now the question is -> "Oil Sand"? What exactly is in it, I mean, can this stuff be "made in the shop" out of "common" ingridients?

Sand casting, it is also called sand molded casting, is a metal casting process that utilizes sand as the mold material. The expression "sand casting" can likewise allude to a product created through the sand casting process. In other words, the mold I made compressed sand.

Sand casting method plays an important role in the production of large metal forms to those goldsmiths who take the time to master it. Though sand casting has been largely replaced by centrifugal casting in recent decades, for hundreds of years it was the most popular of all casting methods.

rod fishing holder homemade surf diy holders rods storage

sand casting process uses naturally bonding sand mold that arises casting defects relating to the mold. Mold material defects are problems resulting from molding material and mold design. There a different mold material defects, here we list down the main defects commonly seen in the casting process.

3d casting jewelry metal slice form digital cad equipment concept

Investment casting, also called lost-wax casting, makes parts from molten metal, usually But sand casting cannot always make the small, intricate parts possible with investment casting. Sand-cast parts usually have to be tapered (with draft angles) or shaped so that they come out of the

casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called 60% of all metal castings are produced via sand casting process.

How to make a casting from making the sand mould to the finished item. The video has been edited to fit the 10 minute time limit of You tube.

Almost all casting metals can be sand cast. Sand castings can range in size from very small to This property evaluates the shape of the individual grains of sand based on how round they are. A green sand mold is very typical in sand casting manufacture, it is simple and easy to make,

Sand casting is a casting-based process that uses a sand mold. Because the cast is made for a specific item, sand casting has been used to cast metallic products of varying shapes, sizes, and weights. The process is so popular that it has been used in lots of different industries.

The Proper Sand Casting Processes. The casting of any object in foundry workshop starts with the pattern making process. The pattern can be made of woods, plastics How can the casting defect as a result of flash be corrected? The failure can be corrected by taking certain things into consideration.

23, 2020 · The sand casting process is a versatile and well understood process. Process refinements over time have helped make sand casting the process of choice for applications in many, many industrial markets. As with most materials and design decisions, a discussion with a metals expert can help drive the best metals decision.

Sand casting molds are the indispensable parts in the sand casting process and play the vital role in casting a range of industry applications. In this blog, VIC will help you get more knowledge about how to make sand molds for metal casting in a simple and easy way to understand.

Sand casting is a process that utilizes non-reusable sand molds to form metal castings. On one hand, casting is a deceptively simple manufacturing process Casting is used to make metal components of all sizes, ranging from a few ounces to several tons. Sand molds can be formed to create

A sand casting mould requires placing a duplicate of the object to be created into sand. The sand is packed tight around the object creating a mould. Let the sand mixture dry until it is hard. The sand casting mould must retain its shape until after the metal or wax is hardened.

Step 1: Basics of Sand Casting. Sand casting is a process that uses a mold made from either metal, wood, or wax to create a Once you have decided on the object you want to make you will need to figure out how you can cast said object and still be able to remove the sand mold from the form.

Green sand formula - how to make molding sand - YouTube. Metal Casting at Home Part 26 How to make Greensand - YouTube. How to Make a Sand Casting Sand casting involves four basic steps: assemble the sand mold, pour liquid metal into the mold, allow the metal to cool, then break away

Sand casting is the most versatile among the manufacturing methods and gives engineers the freedom to design complex parts from an unlimited number of metals and alloys. Over 70% of all metal castings are produced via this process. Sand casting can be produced in a wide range of sizes from

Sand casting, also known as Sand molded casting, is a metal casting process characterized by Sand as the mold material. Both Sand casting and die casting have advantages and disadvantages. Engine blocks are of many different sizes. From very big/massive size (Ships engines) to small

Sand Casting is the process of using sand to produce a negative mold to pour whatever medium you what your cast to be. The sand itself is not normal sand in most cases, it has Also known as sand molded casting "sand casting" can also mean the object that has been cast via the casting process.

The sand casting process can be used to produce shaped parts of nearly any design, including large parts and those with internal passageways. The oldest known casting process, sand casting can be traced back to earlier than 1000 Process controls, material options, tolerance capabilities,