How to make your own o rings. Смотреть позже. Поделиться.

ring gland male standard installation proper

washer husky pressure 1750 parts replacement electric wand ring power fix psi

ring machine installation asp external

Paper rings are an affordable, artistic, and attractive way to show someone you care or to wear yourself. The most intricate paper rings are called To make a butterfly ring, cut a strip of paper out of a paper sheet. The strip you cut out should be about 1/8th of the paper's width.[10] X Research source.

Making the best use of this Forum. FAQ559-716 How to get answers to your SW questions. FAQ559-1091 Helpful SW websites every user should be O-Rings in a working/compressed state will always have at least one flat surface (if ever so small) (kinda like a rectangle with rounded edges in

wax toilet ring replacement remove

O-rings are the epitome of elegant engineering: The ring itself costs only a few cents, and the groove it goes in is simple and easy ... A viewer shot in a request on how to make an o-ring groove in Alibre. He caught me at a good time - I was about to start another ...

gasket crankshaft

Make your own O-rings and tubing from silicone! The object in this picture is a homemade submersible camera housing, made possible by the silicone You may want to make a few lengths of this tubing at once, if for no other reason that to test how the cure is coming along. Just cut a section of your

How To Make O-Ring Cord. Square-Cut Rings. The Seal Man's O-Ring Handbook™. How To Achieve Optimum Performance of An O-Ring. The successful use of O-Rings depends upon many factors

How to make Rings - Detailed Lessons. Mostly learners on the bench want to start off by making rings. Now, there are thousands of ring designs all adhering to the same design foundation. We offer jewelry lessons on how to make a wide variety of rings from beginner level to advanced

How To Blow An O Like A Pro 2 0. How to Blow Vape-Os!

How to use O-ring seals. O-rings are very commonly found in pumps, cylinders, connectors and valves, helping to seal joins between separate parts and prevent leaking of fluids and gases. They're used with static, dynamic, hydraulic and pneumatic components, making them an especially

O-rings are also used as light-duty, mechani-cal drive belts. More information, including design criteria on O-ring drive belts and their application will be B. The seals can be made to seal satisfactorily between reciprocating pistons and cylinders at any fluid pressure up to 5000 psi. There may be

O-rings are the epitome of elegant engineering: The ring itself costs only a few cents, and the groove it goes in is simple and easy ... A viewer shot in a request on how to make an o-ring groove in Alibre. He caught me at a good time - I was about to start another ...

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round

How to make an o ring by o ring cord? At first, to calculate the correct length of cord required, use the formula ((OD+ID) / 2) x Pi = Length. Lastly, Spread a thin layer of Adhesive O-ring Glue over one side of the cut (a thin layer provides the best results). In order to join the two sides cleanly, use the

How to make bubbles. Another piece of prop-based wizardry, this produces a huge bubble with vapor trapped inside. How to do it: Blow a thick milky O ring then use your hand to push it, and tap down on the side of it twice in quick succession to bend it into a triangle.

O-ring seals are best in dynamic applications when used on short stroke, relatively Make sure that the O-ring OD is not larger than the groove OD to ensure a good seal. In the case of a trapezoidal, or other irregularly shaped groove, first look at the pressure direction and then decide on how

I've made O-rings by gluing ends together, but those were for static applications. Wasn't the OP talking about moving parts? That might make the "glue it Hell, you don't even need the CNC if you know how to use a rotary table, but it takes longer. MIght need to spend a little time with an X-acto knife

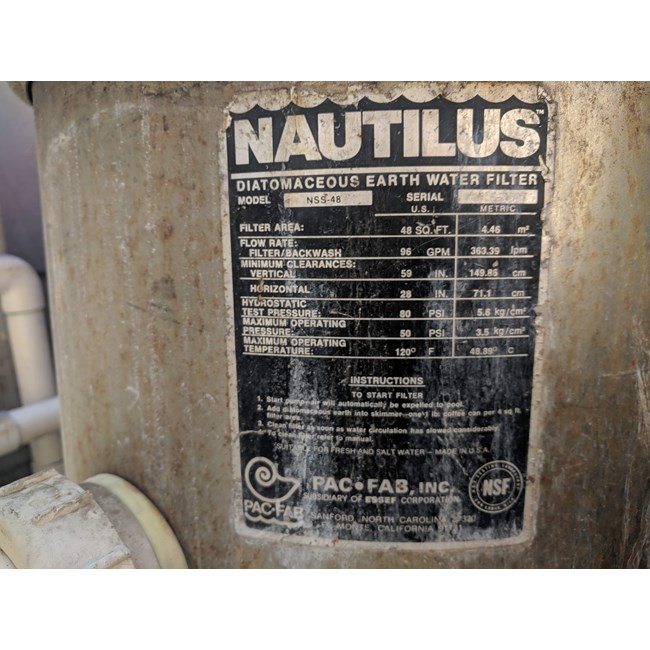

filter ring stainless nautilus tank inyopools

O-rings are a form of gasket or seal that features a round cross-section. They are commonly used to prevent leaks of either fluids or gases from occurring in products, systems, or machinery and find use across a The factors that are usually considered when selecting a material for an o-ring include

The actual process of making the O-rings is alarmingly simple: You're essentially just gluing the ends together. Be sure to use an appropriate glue for your O-ring material! For nitrile, a standard cyanoacrylate superglue will do the trick. My preference here is for Loctite's Power Flex superglue.

In this instructional video, you'll learn how to measure and cut custom size O-rings. The example uses nitrile O-ring cord bonded with Weicon VA 8406 I want to make O-rings to fit in a groove within a cylinder through which a piston submerged in oil has to travel. If the join isn't perfect I am sure it

The softer O-rings may make a better seal, were the tougher O-rings will have better wear resistance while letting minute amounts of fluid by. · O-ring Compression: Again, there should be some compression to guarantee a good seal, but no so must that the O-ring cuts rather than deforming.

Another How-To here today that could hopefully help you out if you ever find that a gasket or o-ring has ever expanded in use and won't go back where An alternative method is to leave the o-ring or gasket in direct sunlight for a few hours, which works by the same principle of making the fuel evaporate off.

How do you make an O-ring groove in SolidWorks? 1 Answer. Click Grooves (Toolbox toolbar) or Toolbox > Grooves . In the Grooves dialog box: To create an O-ring groove, click the O-Ring Grooves tab.

when made of elastomer — according to material type. l Can function at temperatures down to How to use this guide Selecting an 'O' ring Selecting a back-up ring Selecting a material How to order. 'O' ring diameter section A and inside diameter B. 4 To order or get further details, call your

How do you use an o-ring? Simply put, an o-ring seal is comprised of an elastomeric circular cross-section into a designed o-ring groove, providing an initial The force required to compress an o-ring is a result of the durometer and cross-section diameter. O-Ring stretch affects the seal compression

chain chainsaw tighten chains tight stihl quick should adjuster need loose

ring retaining installation external shaft automated spirolox smalley

Video for How To Make O Rings How to make free blue o-ring o-rings for mechanical ... How to make an O-ring - O-ring Splice jig - YouTube · I want to make o-rings to fit in a groove within a cylinder through which a piston submerged

How Making the Right Choice Keeps Your Hydraulic Fitting Connections Leak-Free. In other circumstances, an O-ring could be pushed down into the female threads, compromising the seal of the connection. O-ring face seal fittings can, and should, be torqued to the recommended specifications.

How to Make Rings in an Hour: Metalsmithing 101 Interweave. How. Details: To make a vulcanized o-ring, continuous length cord is cut to length and then joined together. A bonding agent is applied to the ends which are then joined together in a mold at a high temperature for a specified period of time.

O-rings are definitely a machine design component you'll want to be familiar with, and in this video, we're going to tell you all about how to Backup rings are very cheap, and effective. They are made of a plastic like PEEK or Teflon, and they usually have a scarf cut to help you install them in the gland.

O-Rings? O-Yeah! How To Select, Design, And Install O-Ring Seals. How To Make A 30 Gallon Per Hour Watermaker Using Off The Shelf Parts.

How to Make a Wire Ring. Ring-a-ding Rings By Martha Umberger Absolute beginners and pros alike will appreciate Martha's wire-wrapped ring design. No soldering required! The whole thing is held together by cleverly placed wire twists and turns and takes advantage of wire tension.