Metal casting is one of the most basic yet most useful manufacturing methods available to designers. These processes involve pouring molten metal The third main step in sand casting is clamping the drag and cope together, making a complete mold. If a core is needed for some internal contours,

Green Sand Formula - How to Make Molding Sand: To makegreen sand or like it also called molding sand (foundry sand) we need 3 ingredients: sand, clay and Metal Casting at Home Part 10 Another Day in my Home Foundry. How to make a casting from making the sand mould to the finished item.

casting mold aluminum sand pouring molten 3d printed

Moulding Moulding is nothing but the mould preparation activities for receiving molten metal. • Tins are made of sheet metal shapes that are used with patterns to make certain internal and external shapes, but at the same time patterns can be removed from the mold cavity • They are thin

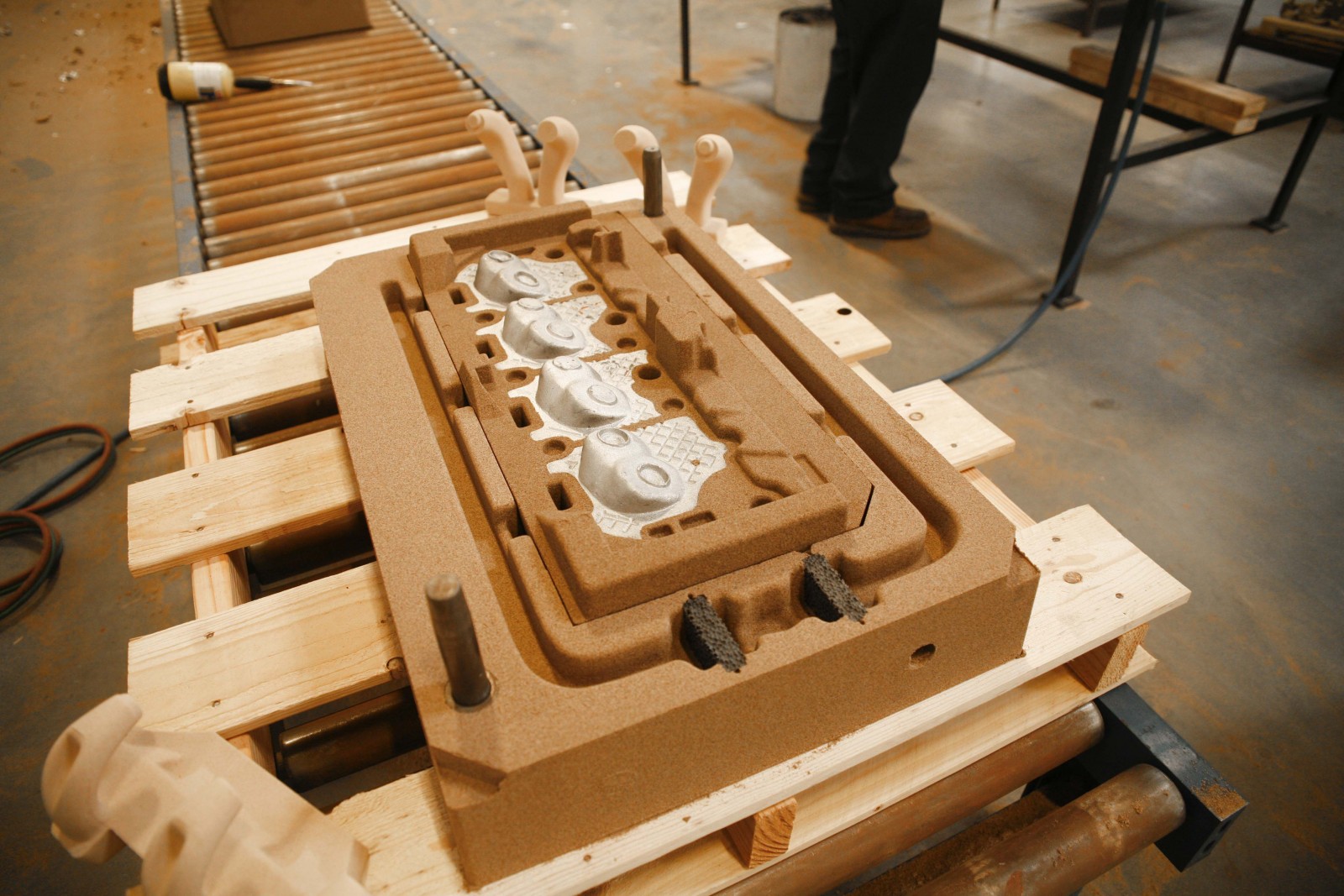

3D Sand-Printing (3DSP) is a relatively new Additive Manufacturing (AM) technology that enables direct digital manufacturing (DDM) of complex sand molds and cores for sand casting applications. Ever-growing interest in this indirect metal AM process is attributed to its ability to rapidly produce

Learn how to identify, clean, restore, season and use collectible antique cast iron cookware. A mold consists of a damp sand-based mixture packed around the pattern in a two-piece box made to be separated to remove the pattern after the sand has hardened, and then put back together leaving

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. There are four main components for making a sand casting mold: base sand, a binder, additives, and a parting compound.

foundry edelbrock casting cast system foundries inside sand manifold intake aluminum heads process techniques general runners mold onallcylinders cores cylinder

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. How To Do Aluminum Casting Using Green Sand in The Backyard Foundry Using A Plaster of Paris Pattern, A Simple Flask

• Currently, all Metal Technologies foundries utilize Disamatic Molding Machines to produce molds for our castings. Disamatics offer a highly efficient means of rapidly and A pouring basin is cut in the open sand and an overflow is made to regulate the thickness of the plate or casting being made.

Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. You can find molding sand online or in specialty metal casting stores. You only need to make a sprue hole in 1 of the mold frame pieces.

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced

casting defects flash

casting cast foundry heads edelbrock cylinder mold process aluminum inside system onallcylinders techniques prev

How to make a casting from making the sand mould to the finished item. The video has been edited to fit the 10 minute time limit of ... Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material.

casting sand process mold molding metals materials texture china

sand casting mold making

Sand casting is a process that utilizes non-reusable sand molds to form metal castings. On one hand, casting is a deceptively simple manufacturing process: anyone who has formed castles at the beach knows sand can be used to make detailed shapes. However in a

How to make a casting from making the sand mould to the finished item. The video has been edited to fit the 10 minute time limit of ... Amazing Cast Aluminum Process Using Sand Mold, Fast Melting Metal Casting Technology

casting sand aluminum molds foundry diy die cast mold aluminium pouring process metal making discover

Sand Mold Metal Castings: Bronze (right) and Aluminum (left). With a completed mold at the appropriate moisture content, the box containing the sand Old wood-patterns, once used to make molds for casting machine parts, are sought out and collected by some for use as interior decorations.

Hello Everyone, Welcome to my make like pro YouTube I'm a product different type of videos content Create like (metal casting, woodworking, restore product more etc. I hope you like my content and keep supporting it.

Casting metal parts from 3D-printed plastic or Styrofoam models is all the rage these days, and for good reason -- casting is a A tuna can, a loaf of bread, and a handful of play sand is all you need to make custom parts. 25 thoughts on "Silicone Molds For Stove-Top Metal Casting". Mynasru says

Learn how to make a shell mold from an STL in Autodesk's video. Watch our webinar to learn how moldmaking using 3D printed masters and reusable or sacrificial molds can allow you to produce parts in porcelain, precious and non-precious metals, silicone and biocompatible flexible materials, and more.

Sand casting molds are the indispensable parts in the sand casting process and play the vital role in casting a range of industry applications. In this blog, VIC will help you get more knowledge about how to make sand molds for metal casting in a simple and easy way to understand.

How do you cast aluminum? You will need a metal melting furnace to bring the scrap aluminum to temperatures above 1,220 degrees Fahrenheit, the point at which aluminum melts. You also need a box filled with sand to make the mold into which you will pour the aluminum. This type of casting

casting mold metal making class molds plaster foundry stonybrook slip sculpture molten ceramic clay plain arts boston

Sand castings are poured into molds made of casting sand, a special sand mixture typically containing 90% silica, plus binders such as clay to hold the particles together (this is a major use of ceramics as refractories or heat-resistant materials). The first operation is to make a pattern (

Different types of metal casting. The basic metal casting process. Learning how to cast metal. Traditional metal casting techniques include lost-wax casting, plaster mold casting, die casting During the Shang Dynasty in China, single-use sand molds were first utilized for casting metals.

Almost all casting metals can be sand cast. Sand castings can range in size from very small to This property evaluates the shape of the individual grains of sand based on how round they are. A green sand mold is very typical in sand casting manufacture, it is simple and easy to make,

I'm planning on making something soon and I am wondering if I could make a permanent mold out of it instead of making a sand mold every time I want to make another. it doesn't have any 3d details so it seems like it would be easy enough but I just don't know to use or do.

Whether you are interested in how to make a mold for reproducing a sculpted figure, an antique picture frame, an industrial pattern, an architectural Whether your original model is made from clay, wax, plaster, sand, concrete, stone, metal, bone or almost any material, making a rubber

First step in creating a bonded sand mold is to create a pattern to be cast. In this case I decided to experiment with party balloons. I chose this material because the patter needs to be made from something that will be completely evaporated by the metal being poured into the mold.

Casting Mold Making Sand casting is a vital process in the process of castings. The process of sand casting has various steps and internal processes in it. How do you make a metal casting mold?

fender flares scale molding rc split miniature diy models wheel ford bodies expedition casting objects primary left right using wide

I think Die-Casting Molds ( NCH precision) can help you. since before when I was a project engineer we made this kind mold for them. The clay mould might break or not be able to hold the molten metal properly. However, a sand mould could prove ideal as it would be able to withstand the

Learn how to cast metal in sand molds using simple techniques and readily available materials. Steve Chastain, a Mechani ... An introduction to small-scale non-ferrous casting. Includes step-by-step instructions on how to make equipment using lo ...

Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must be destroyed in order to remove the part, called the casting, sand casting typically has a low production rate.

Making a sand mold for metal casting process - learn new thingsПодробнее. How make A Gear with Metal Casting TechniqueПодробнее. Brilliant Technique of Metal Casting Using Sand MoldПодробнее.