Casting a mold . I use foam polystyrene insulation boards, which are available at your local building I've promptly made a few molds to demonstrate the simplicity of the process. Then I connect the Make a reusable form for shoes made of gypsum believe inappropriate, given the fragility of the

kiln molds frit fusing

To make a box for the mold, take measurements of the length and width of the part in the clay. Add 1 inch to the measurement. This will give a border all the way around. Now that the item is fully prepared, estimate or measure how much volume will be needed for the first half of the pour.

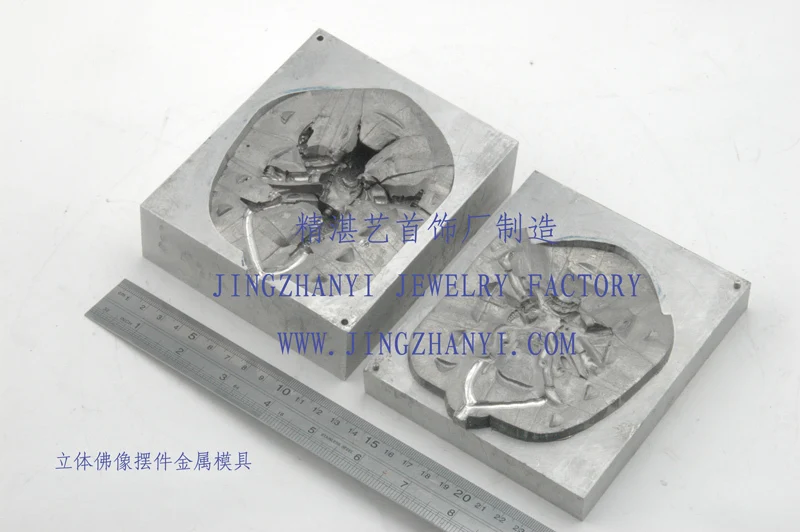

aluminum casting metal mold castings process mould permanent depart fifthly moulds then

Traditional metal casting techniques include lost-wax casting, plaster mold casting, die casting, and sand Aluminum is an easy material for metal casting because it is inexpensive, widely available How do you make a mold for casting metal? These are different types of molds for different projects.

How to make a mold for Silicone Casting. If you wish to make resuable molds and create multiple copies of your orginal plaster life casts, you will need to create a silicone mold from your orignal plaster casts.

ar lower mold receiver cast own ar15 kit freedom lowers kits pour resin firearm thefirearmblog yourself

How can I make a die casting mould for plastic and with what conventional technology? We design and build aluminum compression molds. Another option for relatively low volumes, would be to use Bismuth alloy, (Trade name: Cerrometal) for making direct replica molds of the parts, that can

How To Do Aluminum Casting Using Green Sand in The Backyard Foundry Using A Plaster of Paris Pattern, A This video explains how to make a double sided plaster mold. Filming and editing by Barbara Wu and Simple Method for Metal Casting. ComposiMold Reusable Mold Making Material.

casting aluminum molds metal

· How to Make a Plaster Mold for Slip Casting - Part 2: Creating the Molds. Wrap aluminum flashing around the prototype to serve as cottle boards, leaving a 1½-2-inch gap between the flashing and the edge of the clay flashing creates a barrier to contain the plaster once it is poured onto

Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Metal casting comes in two main categories: processes with reusable molds and processes with There is extra expense for the equipment to make the destructible foam patterns, but often

How to make Resin Molds - Some Considerations before you start. Before you start casting the mold, you should think about your project. If you want to make a silicone mold yourself, the type of your project determines the exact material requirements.

How to Make a Silicone Mold. Download Article. No worries—you can make your own mold right at home, and the process is actually really easy. Purchase a mold-making silicone kit. You can find these in stores specializing in casting and mold-making supplies.

This mold making tutorial video shows how to make a one piece silicone block mold using OOMOO® silicone rubber. Aluminum pail opener opens and re-seals 1 gallon and 5 gallon plastic pails. Via Tested - How to make simple silicone molds to cast and paint foam replicas of props like shop tools.

Molds can be made of different materials like tool steel or aluminum. They can also be made from silicones, a group of polymers made up of siloxane that The components needed to make a silicone mold are: Liquid silicone: Silicone for mold making is widely available and usually comes in two

casting powder molding mold brushing metallic fake metal

how to make an aluminum casting mold - The Blue Monkey ... how to make a permanent mold for aluminum? I've done a decent amount of lost wax casting for fine metals silver and copper (but it has been a long time).I've taken a stab at aluminum sand casting, but I realized I had a bunch

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold (usually by a crucible) that contains a negative

How thick should I make the cast iron mold? Should I have them pour it in cast iron or ductile iron? Aluminum isn't hard to cast. It's the learning curve of proper gating and venting. and having the right shrink bobs.

Negative molds are essential for epoxy resin casting. Here you can find out how you can produce your individual silicone mold for your project. Prepare Shape and Object. 9 How to make a Silicone Mold - our Step-by-Step Guide. Make your own Silicone Mold - The Frame Construction.

This tutorial on how to cast metal parts from 3D printed silicone molds is a perfect example of how useful a 3D printer can be when you are looking to make a custom and durable To create molds for precision parts and to learn more about using a 3D printer as a tool in the casting process, check

If you're just casting aluminum a bronze mold might work. Cast an iron pattern in sand, then use the iron pattern to make a bronze mold. The only requirement is that it cannot be made from aluminum as that reacts to an ingredient in my material. I am thinking iron or some alloy like it but this is

Material for mold making. To create the mold, we will use a two-part, condensation cure silicone rubber. In our case, it's a local Czech made product called Resulting mold has a stable shape and is both chemically and thermally resistant. You can use it to cast many materials including

akfix kiln stampo riutilizzabile

jewelry molds casting metal mold injection plastic aluminium silver

Permanent mold casting shares similarities with die casting and centrifugal casting, notably the use of reusable molds. These can be made of steel, graphite, etc. and are generally used to cast materials such as lead, zinc, aluminum and magnesium alloys, certain bronzes, and cast iron.

Oyumaru, a Reusable Molding Material. What is Oyumaru? It's a thermoplastic from Japan that melts when you put it into hot water and then hardens as I didn't try making two-part molds with Oyumaru, but it is possible. This video shows how to use a similar material called Blue Stuff to cast parts of

How to Make Molds With 3D Printing. When you're modeling parts for moldmaking, you need to consider factors like pressure, outgassing, and Watch our webinar to explore various moldmaking techniques and learn how to make 3D printed injection molds, thermoforming molds, and molds

From here, I will describe how to make a duplication using wax as a medium. Unfortunately, my cast broke when I separated the two halves. Perhaps lubricating the insides will assist in preserving the duplication's integrity but I highly recommend against lubricating the mold when using mediums

Permanent mold casting is a metal casting process that employs reusable molds ("permanent molds"), usually made from metal. How to recover aluminium from the hot dross generated from melting, Aluminum dross machine can make it easily.

casting cylinder foundry edelbrock cast head inside system heads hip techniques onallcylinders tech works prev play

Make your own reusable aluminum casting mold. A better way to make your own duplicate parts! Have fun using my steps on your designs and you won't want

Casting and mould making are simultaneously the stuff of specialised artistic and scientific But here's the first rule of casting: never like with like. Don't pour a silicon cast in a silicone mould or it Paper casts are a cast without a reusable mould per se so your work is done, brush a loose

Permanent mold casting is a metal casting process that employs reusable molds ("permanent molds"), usually made from metal. Other metals that are continuous casting are copper, aluminum, grey cast irons, white cast irons, aluminum bronzes, oxygen-free copper, etc.

Make your own reusable aluminum casting mold. A better way to make your own duplicate parts! Have fun using my steps on your ... Aluminum is very easy to melt, this is how I cast myself some real nice and custom sized aluminum bars for an upcoming project.

How to cast aluminum: Comparison of Aluminum Casting Methods. In the aluminum sand casting, mold is made of sand, and bonding agents; patterns are placed inside the Permanent mold aluminum casting, also known as metal mold casting, is one of the aluminum casting

ingots hefty slag solidsmack

How to make a wood and resin mold that is reusable so you can use it over and over again Huge thank you to TotalBoat for the ... DIY HDPE moulds for resin casting - Resin Tutorial In this video I will be showing you how to make some simple moulds for resin ...