How to make a casting from making the sand mould to the finished item. The video has been edited to fit the 10 minute time limit of ... Aluminium alloy wheels casting process, The method of making Aluminum Alloy castings using permanent mold |.

Jackie Head takes you through the plaster mold making process, so have a look and cross "learn how to make a plaster Before wrapping the aluminum flashing around the first plaster mold section to pour the second part of the mold, apply several coats of Murphy Oil Soap to the surface of the plaster.

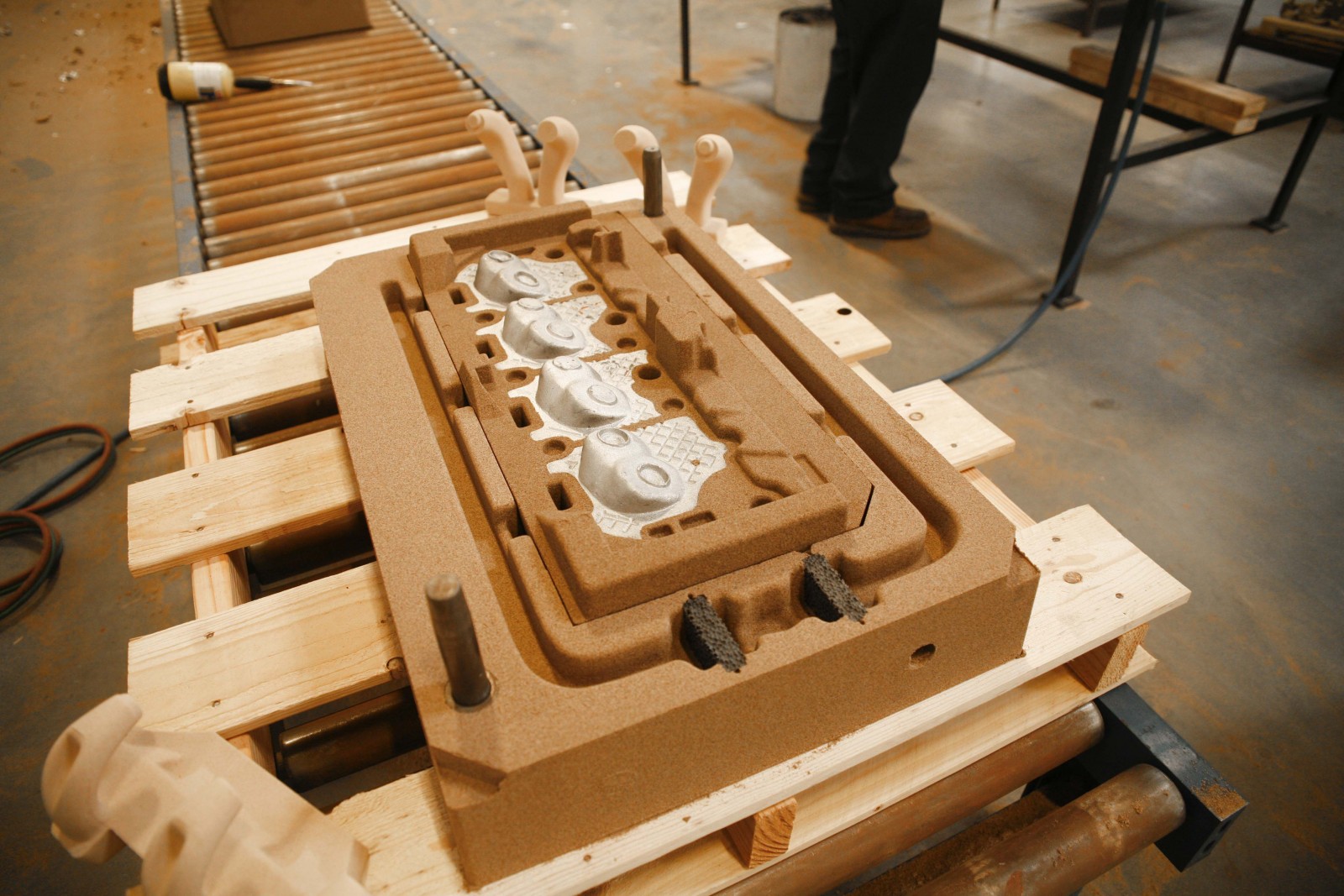

Aluminum Casting Mold Making uses steel molds to produce a large number of identical castings. For aluminum, like other metals, molten metal is pressed How to sand cast aluminum? One of the techniques for making an aluminum mold is called sand casting. It involves mixing fine sand,

How to make the rubber mold in two parts and how to cast the miniature duplicate. Join me as I show you how to make an adjustable and reusable mold for casting.

Many hobbyists delve into the world of metal casting to produce unique pieces. Some of these items are decorative while others serve a specific function. So permanent molds would be machined from a metal that can withstand molten brass or create wax patterns for an investment casting process.

Aluminum Casting Using Sand Mold Method Subscribe my Channel For More Videos Permanent Mold Casting, Gravity Casting ... ... work as a mold making material. to my surprise it worked really well as a reusable mold for both molten metal and concrete.

Make your own reusable aluminum casting mold. A better way to make your own duplicate parts! Have fun using my steps on your designs and you won't want

Traditional metal casting techniques include lost-wax casting, plaster mold casting, die casting, and sand Aluminum is an easy material for metal casting because it is inexpensive, widely available How do you make a mold for casting metal? These are different types of molds for different projects.

And unlike sand molds, silicone molds are reusable. Of course if aluminum is still your material of choice, there's no need for a complicated foundry. So after 45 minutes you are "go!" for making a first casting with epoxy. I noticed that it keeps shrinking for some days - left some in a mini (1cm^3)...

How to make a wood and resin mold that is reusable so you can use it over and over again Huge thank you to TotalBoat for the ... DIY HDPE moulds for resin casting - Resin Tutorial In this video I will be showing you how to make some simple moulds for resin ...

7 How to make Resin Molds - Some Considerations before you start. 8 Supplies you need for the Production of Silicone Molds for Resin. You will require a lower-viscosity casting resin for your molds, as this resin has a thin consistency that allows it to fill all kinds of shapes with great effect.

How can I make a die casting mould for plastic and with what conventional technology? You could make a mold from a sand cast. But as Elizabeth Greene commented, you will need to do some We design and build aluminum compression molds. Another option for relatively low volumes, would

casting cast foundry heads edelbrock cylinder mold process aluminum inside system onallcylinders techniques prev

How to control sand aluminum casting shrinkage? In aluminum sand casting, shrinkage happens when the molten aluminum alloy is poured into the mold cavity and cooled down. By knowing the solidification time of the casting, you just need to make the modulus of the feeder Mf is higher

Structure of die casting mold is complex an d there a re. many parts of mold which play different roles in different. places, so that different m aterial used to make die casting m old should have a certain. hardness, abrasive resistance, inten sity and toughness. And this material should be easy to process.

roberts rick edelbrock dr inside heads techniques onallcylinders performance gm interview gen takes development foundry casting cast system prev

In casting, a hollow mold is created from a master, which could be hand-sculpted or 3D printed (as seen in a video tutorial from BJB Enterprises on how to make You can print a detailed master for casting using a material like Formlabs Castable Resin, which burns out to create a reusable mold.

Rubber Plaster Mold Casting process for aluminum castings at Armstrong Mold Corp How to cast a pewter metal coin using a torch, spoon, and silicone mold not even intended for metal casting. Make your own reusable aluminum casting mold. A better way to make your own duplicate parts!

edelbrock casting onallcylinders foundry techniques cast inside system heads

Desired Casting Resin (used here is a 1:1 mixing ratio). Mold Release. Popsicle Sticks. The item can be anything from an already existing plastic part, to a piece of foam that was carved and shaped to make a custom piece for cosplay (or even a 3D printed part you would like to make more of).

Permanent mold casting is a process of casting metal that employs reusable, or permanent How to make a casting from making the sand mould to the finished item. The video has been edited to fit To help with casting aluminum soap dishes, Diecaster D designed, machined, and assembled

In the permanent mold aluminum casting process a reusable metal mold is used in place of an expendable sand mold. Our Shell Sand Cores are made in house using a resin coated sand which is blown into a heated steel corebox. The sand is cured in the corebox to produce a hard shell on

low temperature casting metal mold

mold steel conclusion cement casting bars aluminum instructables

Make Reusable Casting Molds with this Putty Recipe | Make How to know what to choose among various suggestions given for How To Make A Mold For Casting? The system can give more than one answer for How To Make A Mold For Casting, we also can't say which the best one is.

This mold making tutorial video shows how to make a one piece silicone block mold using OOMOO® silicone rubber. Learn to make quick and easy reusable silicone molds for candles, perfect for the Christmas season.

Aluminum Castings - how permanent mold, die casting, and sand castings compare - Batesville Casting. This video explains how to make a double sided plaster mold. Filming and editing by Barbara Wu and Simple Method for Metal Casting. ComposiMold Reusable Mold Making Material.

Aluminum die casting is a manufacturing process for producing accurately dimensioned, sharply defined, smooth or textured-surface aluminum parts through the use of reusable molds, called dies. • The aluminum casting dies that are created using hardened tool steel must be made in at

Permanent mold casting is a metal casting process that employs reusable molds ("permanent Permanent mold casting involves molds and cores of steel or other metal. How to recover aluminium from the hot dross generated from melting, Aluminum dross machine can make it easily.

casting heads cylinder cast edelbrock inside foundry techniques onallcylinders process mold aluminum system

If you're just casting aluminum a bronze mold might work. Cast an iron pattern in sand, then use the iron pattern to make a bronze mold. Can I cast silver in a metal mold? If so, what type of metal would I use? Happy to make someone a mold in exchange for letting me pick your brain for a

foundry edelbrock casting cast system foundries inside sand manifold intake aluminum heads process techniques general runners mold onallcylinders cores cylinder

How To Use ComposiMold Reusable Mold Making Material {Smart Art May 2017}Подробнее. Two Part Mold Making and Casting of a Lobster Claw with a Reusable Mold Making MaterialПодробнее.

die casting mould making mold extrusion moulds export 3d cnc machinery alloy

How to Make a Silicone Mold. Download Article. Silicone molds come in all kinds of shapes, sizes, and designs, but sometimes you just can't find the perfect mold for a piece you're working on. You can find these in stores specializing in casting and mold-making supplies.

epoxy resin kiln hdpe akfix

From here, I will describe how to make a duplication using wax as a medium. Make sure to wash out any remaining soap as it will distort the shape of Hi, I'm going to ale a mold for a bronze casting and am torn about the medium to use. I am casting a finale, a pyramidal shape with a height of about

Casting and mould making are simultaneously the stuff of specialised artistic and scientific endeavours and the backbone of mass production. Allow to dry and gently remove from the object. Paper casts are a cast without a reusable mould per se so your work is done, brush a loose

Permanent mold casting is a metal casting process that employs reusable molds ("permanent molds"), usually made from metal. The most common process uses gravity to fill the mold, however gas pressure or a vacuum are also used.