The metal is heated until molten (liquid) a mould is made using silica sand or another property that the molten metal will not adherer to. The molds are normally in 2 halves to allow them to come apart following cooling. The mould is filled to a predefined level and the mould left to cool for a period

How to make a casting from making the sand mould to the finished item. The video has been edited to fit the 10 minute time limit of ... I made a catalyzed silicone rubber mold using a Coyote Skull and then poured a molten metal alloy made out of tin and bismuth.

metal forming forging types technology machinemfg

Learn more about the metal casting process and how GK is making strides in expediting and In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity Metal casting is arguably the earliest and most influential industrial process in history. It's used to

Metal Casting Process Brass Vessels Making with Brass Molten Metal using sand mold , Brass Pot HOW TO… PART 1 'SILICONE MOULDS FOR METAL' This is the first episode in my new series of Here I make a mold for casting aluminum or copper, or tin or another type of metal. these will be ...

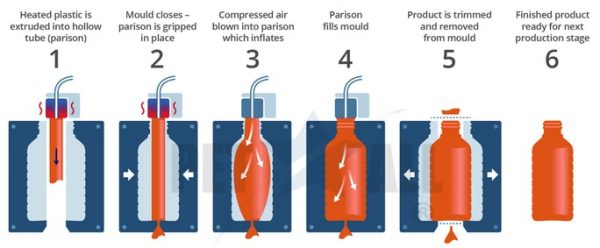

extrusion injection containers manufacture differs lamination

7 How to make Resin Molds - Some Considerations before you start. 8 Supplies you need for the Production How to make Resin Molds - Some Considerations before you start. Hot glue gun with warm-up time from 3 to 5 minutes. Perfectly bonds metal, cardboard, plastic, wood, electronics, etc.

When pouring molten iron into a sand/clay mold, why doesn't the mold melt? Especially for ingot casting or metal molds. I also wanted to provide some context I'm attempting to make a target for shooting practice that would use a sheer thickening fluid to slow the bullet but my issue is how to

mold bullet bullets soapstone early musket history development bess artifacts firearms technology

Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Look for mold frames online or from specialty metal supply stores. As long as it is sturdy, the specific material used to make your mold frame does not matter.

A mold made of metal works for low temperature metals . To cast higher temperature metals like copper base and aluminum you would best use foundry materials for a mold , essentially sand with some binding agent. I don't think anything can be made without problems.

Clay can be used as a mold for molten metal butyou have to fire it first. Clay that has just been left to dry still has some water in it. It's usually done using a centrifuge for small objects in order to make the metal flow into all the parts of the mould. For big, crude, castings like cylinder blocks, a

You can make a mold out of silicone. Here is a YouTube video that explains how to do it: Good luck with your project. 183 views ·. to increase the solidification time of the molten metal to prevent freezing of molten metal before it can fill the mould cavity.

Casting means pouring molten metal into a mold with a cavity of the shape to be made and ... Green sand formula - how to make molding sand To make green sand or like it also called molding sand (foundry sand) we need

In permanent mould casting, molten metal is poured under gravity into a metal die so it is often referred to as gravity die casting. Permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent, high thermal conductivity molds.

Learn how to make a shell mold from an STL in Autodesk's video. Watch our webinar to learn how moldmaking using 3D printed masters and reusable or sacrificial molds can allow you to produce parts in porcelain, precious and non-precious metals, silicone and biocompatible flexible materials, and more.

Such steel molds are very important because when, for example you made your home foundry, bought or made a crucible and ready to melt some metal, you can unexpectedly find out that you don't have where to pour molten metal. For this mould I took U-Section and cut off a piece of it.

the capability of molten metal to fill a mold cavities is called fluidity, it consist of two basic factors ; characteristics of molten metal and casting fluidity allows for a full casting mold and reduces the chances of shrinkage or porosity.

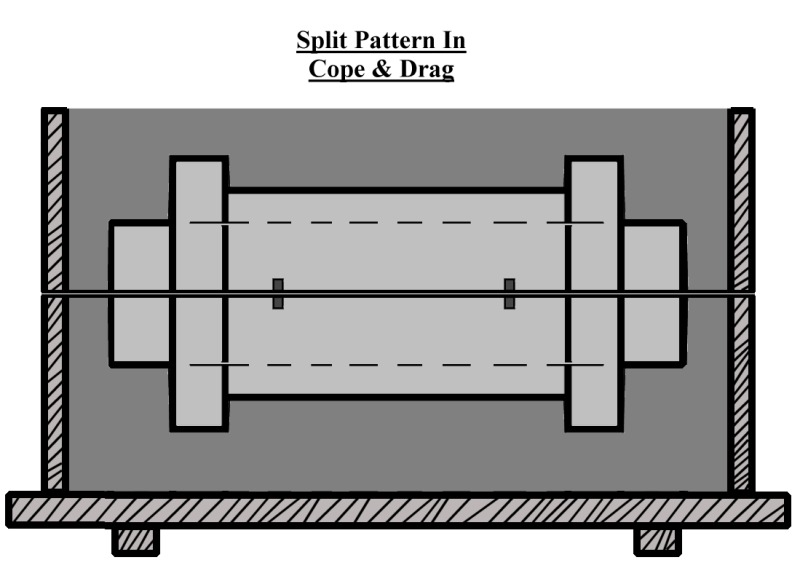

Preparation to make sand molds for metal casting. Making molds in the foundry or DIY with VIC. Strength: When a mold is subjected to external forces such as moving, assembling, or molten metal pouring, it must retain How to make sand casting molds for metal casting? 1. Making drag molds.

Moulding Moulding is nothing but the mould preparation activities for receiving molten metal. • Tins are made of sheet metal shapes that are used with patterns to make certain internal and external shapes, but at the same time patterns can be removed from the mold cavity • They are thin

manufacturing fixture shearing injection foundry milling bertoli gianfranco

During metal casting, molten metal is transferred from a crucible into a mold to create a positive metal cast Metal casting processes have been known for thousands of years, and have been widely used for How do you make a mold for casting metal? These are different types of molds for

metal casting terms mold castings

ingot playdough plasticine welding

My friend made a mystcraft world and found huge lakes of molten cobalt, but neither one of us knows how to make it inot ingots. Any molten metal can be used as a substitute for water, just be aware that not all liquids can be sucked up by all pumps, I created a world with molten liquid red metal (

This mold making tutorial video shows how to make a one piece silicone block mold using How to make a support shell for a brush on silicone mold using Plasti-Paste trowelable plastic. The metal cold-casting process is faster and much less expensive compared with foundry casting of molten metal.

If you have a mold you can usually make a negative from it with a corresponding loss of fidelity, but I am not sure the process would be any easier than starting Honestly, I think if one were to make a spun glass parabolic mirror, a molten metal mold release would be useful in that by forming a paraboloid with a uniform

Plastic injection mold,designed as a hollow metal block with cavities, is used to give shape to molten plastics via the process of injection Plastic injection molding is known as one of the most commonly used technologies for long production periods because it is very fast. But, how fast?

Once metal is melted, the molten material can be poured into molds. Molds can be made from sand or whittled wood. If sand is used, it is typically contained in a To mold a replica of an existing object, create a solid wooden box with two equal halves. Pour your perlite mixture into each half of the box.

- Molten Metal Challenge, Making a 100kg / 220lb Steel Anvil - Melting Steel, Pouring Molten Metal, Red Hot Water Quench, Mixing Molten Metals. How to Make a Steel Mold for Molten MetalsПодробнее.

Making of iron box from brass Molten metal casting process using sand mold Best molten brass metal laundry iron Box making ... HOW TO… PART 1 'SILICONE MOULDS FOR METAL' This is the first episode in my new series of model making How to Make a Steel Mold for Molten Metals.

3 POURING THE MOLTEN METAL After heating, the metal is ready for pouring. Introduction of molten metal into the mold, including its flow through the gating system and into the cavity, is a critical step in the casting process. For this step to be successful, the metal must flow into all regions of the

Making the Silicone Molds for Home Pewter Casting with SmoothOn Rebound 25 PT. Here is a brief video demonstrating how to pour molds of clay sculpted patterns. then pouring molten pewter into the sand mold to get his finished product, which has a shape and texture co-created by

casting cast foundry heads edelbrock cylinder mold process aluminum inside system onallcylinders techniques prev during

Basically you pour in the molten metal, and swing the casting around your head on a chain or something. - Obtain some sort of molding type wax, investment, and maybe a vaccuum pump (can get from science dept at school, i think) - Make a wax ring carving identical to how I want it - using

sand casting molding core patterns boxes shape form

Some time ago I've made a small steel mold for casting ingots and now decided to make a second one. This one will be much bigger. When it's ready it will

pattern drag sand cope split core mold foundry burner railway bob making construction pins ram restorations

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold (usually by a crucible) that contains a negative