The cost of a mold rarely makes sense for small batch parts, and designs normally include the maximum number of part copies possible specific to a factory Can you give me advice or info about how to desing and make them? It is better if the mould has metal charge like steel or aluminum?

We offer a great variety of mold making materials. Whether you need alginate for making a mold or It could be as complicated a multi-part aluminum injection mold used in the manufacture of plastic Most mold making materials are utilized are made from natural or manmade rubber because of

Metallic aluminum has many properties that make it useful in a wide range of applications. It is lightweight, strong, nonmagnetic, and nontoxic. Aluminum compounds have proven useful for thousands of years. Around 5000 , Persian potters made their strongest vessels from clay

Learn how to use injection molding to mass produce plastic parts. A mold can cost anywhere between $3,000 and $100,000+, depending on its complexity, material (aluminum or steel) and accuracy (prototype, pilot-run or full-scale production mold).

How to Make a DIY Ingot Mold for Aluminum, Lead or Zinc Casting. In this video I show you how to make 8 small molds for aluminum, zinc or lead ingots, each about 4" by " by " using ...

Making a Fiberglass Mold. The Plug. In order to have a form from which to develop your mold, you must either build the article from scratch using wood, plaster, polyester putty, formica, sheet metal, etc. or you must have on hand a completed article which you wish to duplicate.

A mold factory made a ×1m aluminum mold according to customer needs. Due to the significant differences in processing equipment and On account of the large size of the aluminum mold, the traditional manual measuring tools are not able to obtain the comprehensive data information of

welding tig tips aluminum metal penetration joint tee tip scale clean rust below torch don too needs etc paint tricks

Making a homemade metal foundry or forge has never been so easy, in this episode we are going to make a foundry to melt aluminum and make In part 3, the final chapter of #TheMetalFoundryProject, I'll try to make the actual motorcycle part by designing them and using a polystyrene mold for casting.

Aluminum alloys are a versatile, and cost-effective mold making material. Howard Precision Metals offers a wide range of aluminum products and extrusions for various industrial, manufacturing Plastic water bottles are manufactured using blow molding, a process in which aluminum mold plate is used.

For molding materials that do not contain abrasives like glass fibers or corrosive ingredients, P-20 Aluminum is very soft and requires extra attention in the design to make sure it is robust enough, and I can't count how many times I have had to deal with galled tools when running P-20 cavities

How to Make a Silicone Mold. Download Article. Silicone molds come in all kinds of shapes, sizes, and designs, but sometimes you just can't find the perfect mold for a piece you're working on.

How to Make a DIY Ingot Mold for Aluminum, Lead or Zinc Casting.

lead fishing weights making moulds wooden

Can you cast aluminum in a plaster mol How do you make a mold for casting aluminu The most commonly used materials is aluminium. The maximum working temperature of

Mold Making. This page shows you how to create your own molds using several different molding compounds. Index. Important notes. I'm going to make a mold of this caulking tube spout. These will end up being spikes for the top of a tower. I've glued the spout down to a piece of plexiglass to

Aluminum mold criteria Advancements in the various types of aluminum material suitable for mold manufacturing have gone a long way toward making it How many parts annually will be molded and what is the life of the program? "We do stretch way outside what others do in aluminum in terms

wax mold casting lost instructables

casting metal foundry backyard making mould metals sand jewelry aluminium castings melting creating crafts tools

casting die process aluminum castings china lg

molding cast aluminum. Melting Aluminum Cans With $20 Homemade Mini Metal Crucible. This homemade metal foundry was made with a mixture of 50% plaster of paris and 50% sand, which are a good How to Make the Simplest Metal Foundry: How to make a metal foundry that works with gas.

Learn mold making basics, from making a mold box to mixing your silicone to de-molding your finished product. There are a lot of silicone options out there - but how do you know which one is right for you and your project? That's where we come in.

Need Help I M Wanting To Make A Mold For Casting Aluminum Out Of. Crafting is how most things are made in minecraft. Classic crafting a way of manually putting things in the crafting table is coming for

UNDERSTANDING OF ALUMINUM - Scientifically. The use of sand as a molding material molds has several advantages. At first, Sand is very cheap. Secondly, it is resistant to high temperatures, it can be used for the casting of many metals with high melting point.

Aug 18, 2020 · How to Make a Mold for Aluminum Casting. His were aluminum, and sometimes brass. In some cases he would machine the mold out of a billet, other cases he would make a pattern from bondo, or fiberglass resin, and then use the pattern to sandcast the actual mold from aluminum.

chocolate crickets covered own cricket farm mold directions reptile

Learn how to create 3D printed injection molds for low-volume, in-house injection molding to produce small, functional parts in production plastics. Stereolithography (SLA) 3D printing provides a cost-effective alternative to machining aluminum molds. SLA 3D printed parts are fully solid and

Whether you are interested in how to make a mold for reproducing a sculpted figure, an antique picture frame, an industrial pattern, an architectural molding, a fossil, animal skin (taxidermy), the 5 Gallon Vacuum Chamber(2). Aluminum Pail Opener(1). AquaCon™(1). Bronze Metal Powder(1).

But, how fast? Though its production speed may be dependent on the complexity of the mold structure, there is only about 15 to 30 seconds interval between The high-quality plastic injection mold making is the core business of Sositar. We have 10 special mold designers, who have rich experience

metal gallium diy lego using figures

9 How to make a Silicone Mold - our Step-by-Step Guide. Make your own Silicone Mold - The Frame Construction. To make a silicone mold yourself, you need silicone rubber. This soft compound, which hardens relatively quickly, is available in specialist shops.

A mold factory made a ×1m aluminum mold according to customer needs. Due to the significant differences in processing equipment and technology, in many cases the mold cannot reach the required accuracy after production. For this reason, mold measuring becomes a necessary stage in

But those are both 1 shot, and I want to make a lot of copies. Any advice around molds? I've got a decent precision but sorta half-assed cnc I know aluminum isn't great for that job, but if I had a more permanent mold, I could just re cast the worn track. Any way to get a reusable mold for

7 How to make Resin Molds - Some Considerations before you start. 8 Supplies you need for the Production of Silicone Molds for Resin. If you want to make a silicone mold yourself, the type of your project determines the exact material requirements. The following list is based on a

mold minnow tail shad inch crappie soft plastics diy

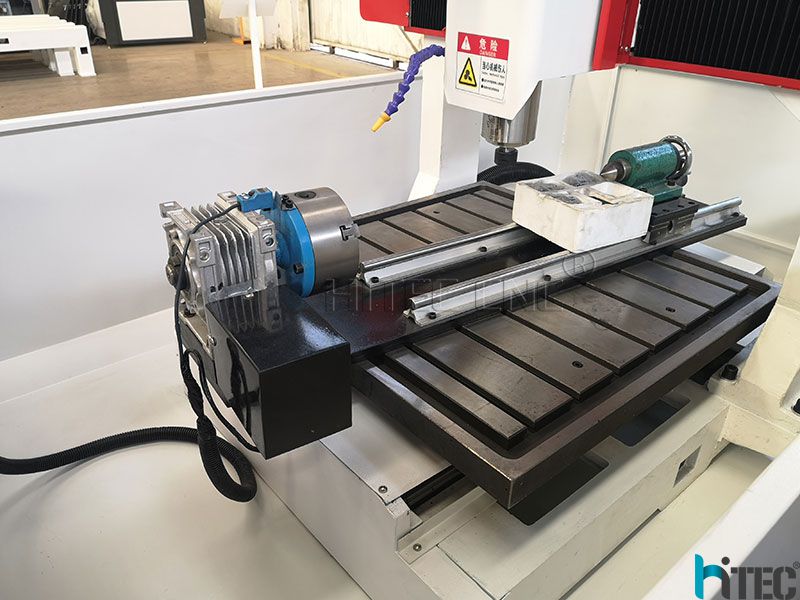

cnc machine milling metal machines affordable

Aluminum injection molding is ideal because it guarantees an easy production of complex products with minimal parts. Also, it guarantees stable products Mold robustness refers to the number of parts a mold can make before it becomes too corroded or worn out. This factor is hugely dependent on

Blow molds and many prototype molds are made from aluminum. Aluminum is a very soft material and requires special polishing procedures. If necessary, move to the finest diamond compound, ivory ½ micron. The finish you require will determine how many diamond compound steps are necessary.

You could make a mold from a sand cast. But as Elizabeth Greene commented, you will need to do some finish work on the casting. It generally has high silicon content for aluminum or aluminum alloy die casting use HT412 the special ash-removing reagent for die casting