Now CNC Milling Machines are not cheap. they can cost tens of thousands of dollars. I am not made of money so I guess a $50,000 CNC Milling One of my responsibilities is to teach the students how to use CNC milling machines to fabricate their projects. During the school year, we get to make all

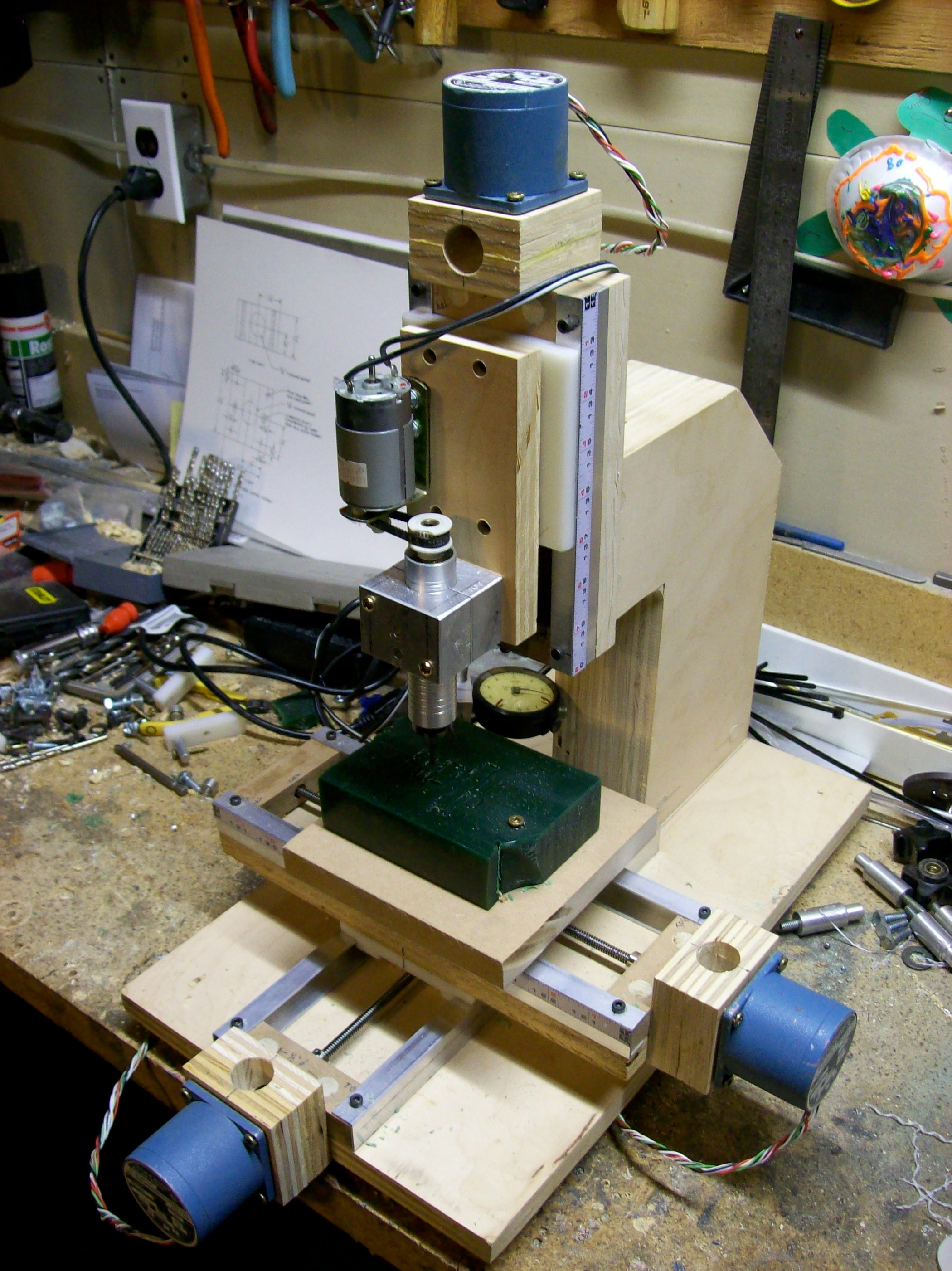

How to build A CNC machine _ DIY CNC mill. This is full video on how to build CNC machine at home. This CNC mill is very rigid it has very high accuracy.

cnc projects

cnc tapping machine holes

Before you make a CNC mill with your hands, you can cast the vertical axis, using a muffle oven. A great material will be aluminium. They will allow you to understand how to proceed. Design can be a signature of three engines, pointing to the need for the disassembly of the two dot matrix printers.

How to Make a Mini Milling Machine- Manual or CNC! by Machine Right in CNC. Have an instructable you think should be included in this collection?

cnc flag projects stand lumberjocks woodworking

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done varying direction on one or several axes, cutter head

Today, I am going to discuss How to make PCB using CNC Milling machine. If you are electronics hobbyists or some professional, first knowledge you must get is making a PCB on your own. It will make you independent from other manufacturer who can cost heavily and ask for two or three days

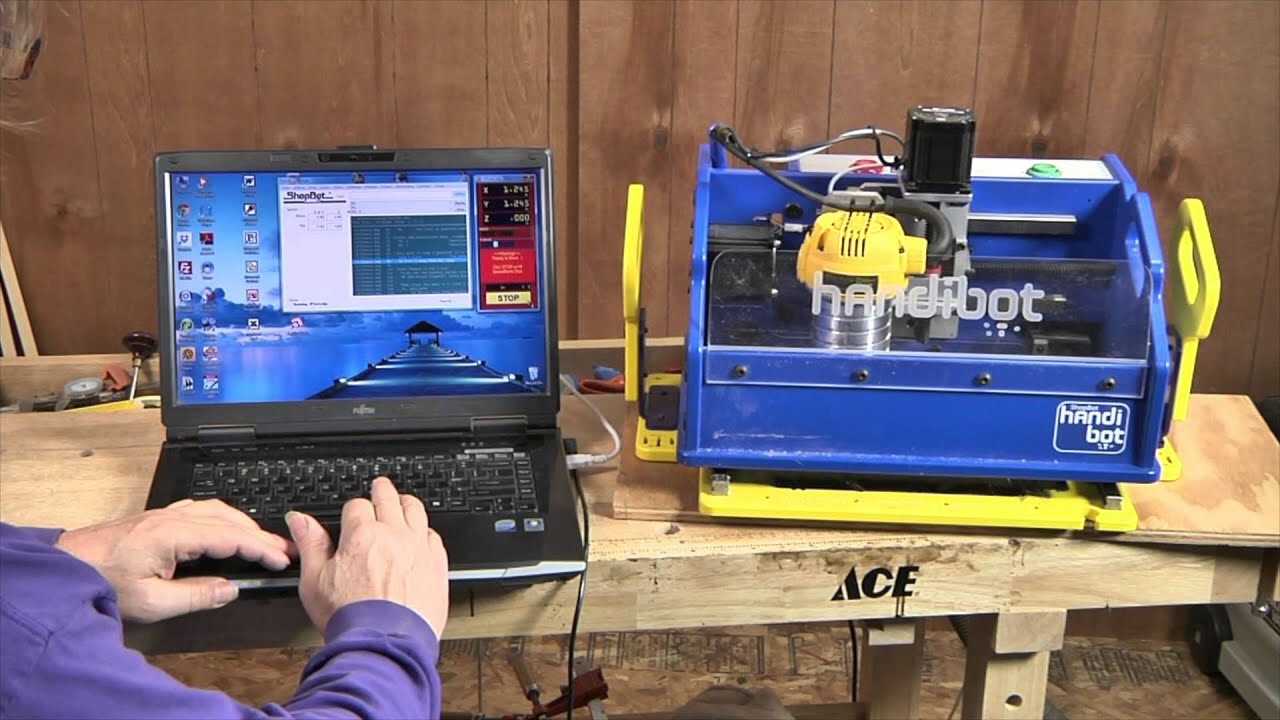

Arduino CNC Mini Mill - System Overview. Part 1 - Electrical System - grblShield, Arduino, power You can find a detailed how to post and a quick start guide to get your basic DIY CNC Controller I really had not planned to make a full enclosure. However, the opportunity arose to take the mill to

CNC milling program example which shows how a cnc program can be made to machine Pockets on a cnc mill. This program example uses Peck milling CNC Mill Program Example A very simple cnc milling machine programming tutorial for beginner level cnc machinists. An easy to understand

CNC Milling - Process, Machines & Operations. CNC milling is one of the most common processes CNC milling is a substractive fabrication method that uses computer numerical controls systems Still, the basics are the same and understanding the more traditional machine is enough to

CNC Mill Project Page: Dr. D-Flo's Instagram: A computer controlled ... Making chips with the new 4th Axis for my homebuilt CNC milling machine. Some testing, and some explanation of how I set it up ...

instructables fresadora fabriquer fraisage torno tubefr nardu

Converting A Mill To CNC. 16 Comments. by For most of the past year, [Joel] has been working on converting a manual mill to a CNC mill with the addition of a computer, brackets and I have about 90% of the parts needed to convert my mill, just need time to make the brackets and put it all together.

CNC Milling Machine Frames are most commonly made of cast iron. Other possibilities include aluminum or weldments with epoxy granite fill. There are pros and cons to consider. The good news is that I have a complete article on how to choose the best Donor Mill for your CNC project.

cnc router diy machine handheld portable tools table complete crafts handibot kit interest

Exploring how replacing EDM manufacturing with CNC milling can help you reduce delivery times, increase your output and simplify workflows. Unattended operations In the past, shops were more apt to run an EDM sinker machine unattended, rather than a CNC mill.

So we are considering purchasing a manual tabletop mill, such as Jet 350017, or something of that sort and converting it into a CNC mill. First post in here. I am a college student and I'm looking to buy my first cnc mill, specifically the Bantam desktop. I was looking to be able to make aftermarket car

I currently have a CNC mill (tormach PCN 1100)for making small modifications to prototypes. It's mostly useful as the only open-frame mill in the shop. If they don't know how to do very, very basic CNC programming, what makes you confident that they

My heavy epoxy granite CNC mill and some Details about the progress building it. This is my first CNC machine project. • Parallel to the making of the machine, we have made a 3D model with Solidworks. This is a rendering from The machine base: Next step was to make the Z axis and X

Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion. CNC Fusion is a small company that machines high quality conversion parts made from 6061 aluminium stock.

This is full video on how to build CNC machine at home. This CNC mill is very rigid it has very high accuracy. How to improve your homemade CNC milling machine I am making a lot of changes to my homemade CNC milling machine to get ...

cnc milling machine spindle diy

CNC milling, or computer numerical control milling, is a machining process which employs computerized controls and rotating multi-point cutting tools to progressively remove material from the workpiece and produce a custom-designed part or product.

Figure out how to select one or more objects with your mouse, and then find the commands that perform the following tasks Note: Of course, it's not that you can't make a competent acute angle with a CNC mill. For example, refinishing the one on the left with a mm cutter would result in

Making a cnc mill. Building my own CNC MillПодробнее. How to build A CNC machine _ DIY CNC millПодробнее. Powerful CNC Mill That Fits on a DesktopПодробнее. How to make beautiful table with CNC routerПодробнее. How to Convert a Manual Mill to CNCПодробнее.

Rather, it is to show how to use CNC to make common types of parts, teach DFM principles, and help engineers become better designers and managers. top cover of a CNC mill as they walk through the shop. • A person leans against a bench where a cutting chip has fallen, resulting in a cut to their hand. •

This CNC mill is very rigid it has very high accuracy. How to build a DIY CNC machine completely from scratch. I designed the machine in Fusion 360 from the ground up and had a ...

cnc router making signs

mill instructables milling

On a typical CNC mill or CNC router setup, installing a Smoothieboard will mean you do the following things On a CNC-mill, dusts, like wood dust for example, can be explosive if they come in contact with a Now you need to move an axis to make sure the stepper motor is turning in the right direction.

How can you build an industrial CNC Milling machine for cheap. Industrial machines are made to run all day, cranking out parts… low down time, low maintenance, etc. What is "cheap"? Are you trying to build a six-axis machining center for $ Or are you wanting a two-and-half axis mill to be a

PCB Milling was on my TODO list. So I thought I'll give the cheapest CNC mill a try that isn't made from card board. You would be ... This is full video on how to build CNC machine at home. This CNC mill is very rigid it has very high accuracy.

This is full video on how to build CNC machine at home. This CNC mill is very rigid it has very high accuracy. It has zero are some info

Learn how to make parts cheaper and easier to manufacture for a CNC milling process in an easy to follow video tutorial filled with examples. A computer numerically controlled (CNC), milling machine is used to transform blocks of raw stock into finished parts by cutting away material.

How a CNC Mill Works. The CNC milling process follows the same steps many other machining types do, including making a computer-aided design (CAD) These guidelines explain how to make web content accessible to people with a wide array of disabilities. Complying with those guidelines

cnc router homemade diy kit machine table milling desktop shapeoko second plasma cutter tutorial control

Raise the milling head by using the 'Tool-UP' button on the Modela front panel. Using the Allen key, gently loosen the hex nut on the rotating part on the milling head Next, you need to set the origin for the PCB miller or CNC. This is done so that the machine knows from where it should start the operation.