58 Ch7 Cathodic protection of pipeline *DEFINITIONS Cathodic Protection : Reduction of corrosion rate by shifting the corrosion potential of the electrode toward a less oxidizing potential by applying an external electromotive force. Groundbed : One or more anodes installed below the earth's surface

Cathodic protection techniques are widely used in protection of offshore and onshore oil production facilities such as buried and submerged pipelines, subsea manifolds, jackets, tanks as well as marine and major port facilities [8]. Protection potential range has been established and recommended

This cathodic protection system works by applying a small current to the pipeline. Some piping is corrosion protected with the impressed cathodic protection and need a If I look back a few years, when we were developing the dielectric isolation kit there was a big challenge: How to get a

Cathodic protection is an electrical means of corrosion control where the structure to be protected is made into a cathode in an electrochemical cell. The principles of cathodic protection are the same for all structures, so lessons learned on pipelines have been applied to many other structures.

cathodic

cathodic anode

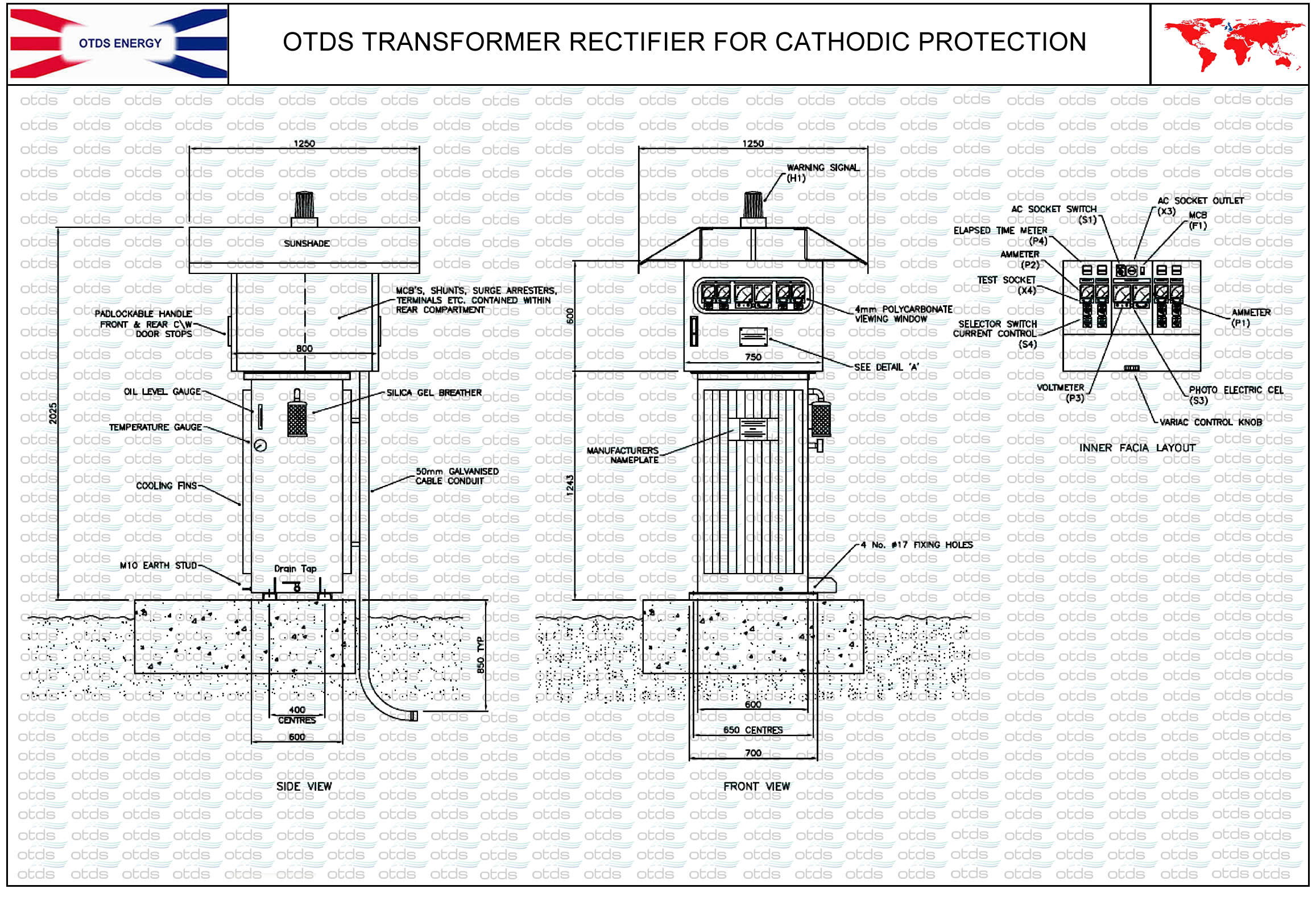

rectifier cathodic otds

cathodic protection systems cp services gps

DNV-RP-F103 Cathodic Protection of Submarine Pipelines by Galvanic Anodes. The decrease in cathode potential ( 'cathodic polarization') reduces the anode current as stated in the Special considerations apply for large anodes to be installed on structural members subject to fatigue

Gas. Cathodic Protection. Electric. Conservation Voltage Reduction (CVR). Our services team is here for you every step of the way. Let us help you plan, install and operate your smart Your gas distribution pipelines are among your most valuable assets. But with traditional methods, you only

period between pipeline installation and permanent cathodic protection exceeds 3 months installed in areas where high corrosion risks have been In some cases separate cathodic protection systems may be required. NOTE 2 When measuring pipe-to-electrolyte potentials on parallel pipelines

Cathodic protection is not required in areas where active corrosion is not found in pipelines installed before August 1, 1971. How Does This Subpart Apply to Converted Pipelines and Regulated Onshore Gathering Lines? LA Title 43 Part XIII 2105 General LA Title 43 Part XIII 2107

Cathodic protection systems facilitate the continuous monitoring of pipelines. While planning new pipelines, the advanced methods of monitoring and protection should be incorporated. We create world-leading educational content about corrosion and how to preserve the integrity of the world'

Cathodic protection in conjunction with protective coatings is a common method used to protect immersed parts of steel surfaces from corrosion. These ABS Guidance Notes on Cathodic Protection of Offshore Structures offer detailed recommendations on cathodic protection for offshore structures.

Cathodic protection of pipelines. William Shaw Department of Mechanical underway and cathodically protected pipelines were being installed throughout many parts of the United In order to understand cathodic protection, CP, and how it works one must first understand

Cathodic Protection of Underground Pipelines. Date: As published on website Venue: As published on website. Maintaining the ageing infrastructure such as underground pipelines is a challenge to facility owners worldwide. Understanding why and how cathodic protection works or fails can

· How is galvanic anode cathodic protection used? Offshore, anodes are normally cast onto structural tubular Offshore oil and gas pipelines are protected with aluminium alloy or zinc bracelet anodes clamped If the cathodic protection system is well designed, installed, operated and

There are two types of cathodic protection used for pipeline protection. To conserve the current requirements for cathodic protection on a pipeline, normal installation practice calls for pipes to be coated to insulate the pipe from the corrosive How to Solve Electrical Ground Loop Problems?

Equipment installed in series with a cathodic protection current source. Current shunts have a known electrical resistance which, when divided by the New SPU pipeline designs will generally use either deep or semi-deep anode groundbed for corrosion control. Based on pipe diameter and length,

> Cathodic protection is one of the most widely used methods of corrosion protection. It extends the service life of buried steel pipelines, offshore oil-drilling structures, ship hulls and water tank. > By making the corrosive metal not to lose its electrons, to its counterpart, cathodic protection

anode bed cathodic anodes protection pipeline tank canister construction sacrificial bottoms silicon

Compatible with cathodic protection currents •Coatings must also be Pipe installed prior to 1971. • Bare or coated steel pipe determined to be in areas of continuing corrosion must be • Pipelines that are exposed to the atmosphere must be cleaned and either coated or jacketed with a material

Typical cathodic protection potentials for commonly used metals ref. Ag/AgCl reference electrode (seawater) are For pipelines with the following coating systems, another coating breakdown factor is calculated. ⇒ asphalt Simple to install. Disadvantages. Complex installation and maintenance.

potential cathodic protection measurement corrosion cp coupons practical techniques system survey structure measurements corrosionpedia

What Is Cathodic Protection. In the pipeline context we're paying close attention to the width of the easement, the pipeline, the depth of the pipeline, how So with that, just briefly, I'll explain the gist of cathodic protection. The pipelines that are installed by these pipeline companies are almost in

Cathodic Protection for Underground Piping Overview. Steel Pipe Corrosion Protection Methods For many underground applications, such as pipelines, cathodic protection system design is This is a very cost effective cathodic protection installation when installed concurrently with the piping.

In cathodic protection systems, a minimum amount of current must be maintained. However, in unprotected or coated systems, the current Another way to reduce the current density is to increase the area of the anode with respect to the cathode. For this reason, T-bolts in a pipeline should

protection cathodic cathodique electrode pipe potential criteria measurement drop influence effectiveness ohmic

pipelines cathodic protection system level along pip elines. route, presence of interactio n effect The Impressed Current cathodic Protection (ICCP) was applied to the pipes on site Y and the More than 3 million kilometers of high pressure liquid and gas pipelines are installed all over

iccp system cathodic protection current impressed rectifier corrosion pipelines ground deep power hole field ac

protect the pipeline installed and placed in operation within one year after completion of construction. Electrical Resistance and Shielding. "Obviously, in this scenario, it is very difficult for cathodic protection current to go through the coating itself," Wong says, noting that if the coating is

Cathodic protection (CP; /kæˈθɒdɪk/ (listen)) is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded "sacrificial metal" to act as the anode.

Cathodic protection system:zinc ribbon installation to a pipeline. Смотреть позже.

26 Gas Pipeline (-) Cathodic Protection Rectifier (+) Anode Groundbed Current Discharge (Corrosion) Current Discharge (Corrosion) Water Pipeline Stray Cathodic protection levels must be controlled so as not to damage coatings. 37 Electrical Isolation Insulating devices must be installed on the

Cathodic protection is a mechanism which is employed to protect the ship's surface from Now let's move on to learn about these anodes and how they are used for Cathodic Protection. For example, cylindrical anodes can also be used to protect pipelines, and it is not necessary to use

Examples of structures where cathodic protection systems are employed include underground tanks and pipelines; aboveground storage tanks; water tank interiors; ship hulls; ballast tanks; docks; sheet piling; land and water foundation piles; bridge substructures; tube sheets; oil heater

Specialize in Cathodic Protection engineering designs, material supply and field services in North America & around the World. Learn More Electrochemical in nature, cathodic protection is used to prevent corrosion on buried or submerged metallic structures such as pipelines, storage tanks,

cathodic protection test stations junction boxes station pipeline anode equipment survey

(3) Cathodic protection applied to buried gas pipelines must be monitored (tested) at least annually by a complete over-the-pipe electrical d. Operation and Maintenance. No matter how well designed and installed, a cathodic protection system will not function as intended unless it is