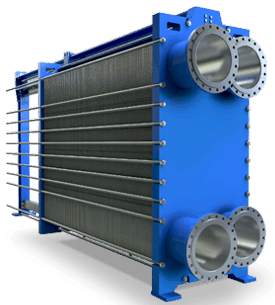

A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. There are four main types of PHE: gasketed, brazed, welded, and semi-welded. The plate-and-frame or gasketed plate heat exchanger essentially consists of a

20, 2021 · A plate heat exchanger consists of parts such as baffles, plates, gaskets, screws and bolts along with other relevant parts. New developmental technologies use flat flanges for direct tube connection which helps to reduce production costs and time. Advantages of a plate heat exchanger include its simple structure, compact size and lightweight.

Maintaining a plate heat exchanger and its related cost is not just a good idea -- it is a necessity for any successful business strategy concerned with its This exploded view of a plate heat exchanger shows the intricacies of the device and how maintaining it can be costly and time consuming if

The heat exchangers are allowed to undergo works and repairs only in case the unit is not under pressure and the temperature of its surface is below 40°C! Do not drop the brazed plate heat exchanger from heights! During the mounting process protect the heat exchanger from shocks!

...thinking that maybe I could keep my two electric hot water heaters, and install a plate heat exchanger for each unit to heat the DHW during the heating season. I wonder how the heat transfer plates are for plugging up. They're full of small passages, compared to a side arm heater.

In this video, Jeff Luff of Alternative Heating & Supplies shows you how to install a plate heat exchanger to a domestic hot water tank. Installing

How is a Heat Exchanger designed? Marine Heat Exchangers. What fluids can a Heat Exchanger operate with? Installation - The heat exchanger should always be installed based on a manufacturers' guidelines. Generally speaking the most efficient way to install a heat exchanger

to install sacrificial anodes. Do not foul as easily as plate heat exchangers. Disadvantages. Less efficient than plate heat exchangers. Require more space to open and remove tubes. Cooling capacity can not be increased, but a plate heat …

exchanger heat plate installation method statement piping connections methodstatementhq

10, 2021 · The plate heat exchanger has the advantage of being expandable, which allows for an improvement in heat transfer capabilities. If the heat transfer specifications adjust, you can easily install plates rather than purchasing a whole new frame unit, saving you time and money.

01, 2020 · Dimple Plate/Plate Coil Heat Exchanger: Although its market share is much less than that of the previous two categories, dimple plate/plate coil technology is the best solution for applications where one of the fluids isn’t ’s also useful in retrofit applications, such as waste heat recovery that wasn’t accounted for in the initial blueprints.

SonFlow plate heat exchangers are specifically designed and built for the operating conditions, therefore sudden changes should be prevented, as Demountable plate heat exchangers can always leak, please take this into account when installing - install a drip tray underneath the heat exchanger.

water heat exchanger plate plant heating distribution facility steam systems installation gauges government repair inc pump dual station

gasketed exchanger

exchanger heat plate alfa laval works countercurrent

What is Plated Heat Exchanger? Plate heat exchangers or gasked plate heat exchangers with broader descriptions are machines that allow heat transfer by moving two fluids with different temperatures on the surface of plates in different types without moving in relation to each other.

Install Plate Heat Exchanger's as indicated unless deviations to layout are approved on coordination drawings. Plate Heat Exchanger shall be installed on the concrete foundations (by main civil contractor) as per approved foundation drawings, ensure adequate space is available for

Plate heat exchanger is widely used for cooling system in automobiles and refrigeration systems. Plate type is only suitable for low temperature and pressure processes, not exceeding than 200 degress Celsius and 20 bars. Plate type is not that pricey and is easy to install. And the good point its

heat exchanger. Fixed plate heat exchangers have no moving parts, and consist of alternating layers of plates that are separated and sealed. Typical flow is cross current and since the majority of plates are solid and non permeable, sensible only transfer is the result. The tempering of incoming fresh air is done by a heat or energy ...

heat exchanger boiler plate plumbing install water existing re pump boilers steam systems heating doityourself

Ton SEER AirQuest-Heil by Carrier Heat Pump System w/Line Set Install Kit. $2, Free shipping. or Best Offer. 31 sold. Outdoor Wood Furnace Boiler WoodMaster 4400 MODEL 5000 sqft. $9, Local Pickup. 52 watching. 12x12 Water to Air Heat Exchanger Hot Water Coil Outdoor Wood Furnace. $ Free shipping. 208 sold. Honeywell ...

All plate type heat exchangers supplied by SONDEX are provided with a name plate. Demountable plate heat exchangers can always leak. We advise you to take this into account while installing. Preferably you should install a drip tray underneath the heat exchanger to prevent leakages onto

Plate Heat Exchangers. 5 x 12 Stainless Steel Plate Heat Exchanger; 3 X 8 Stainless Steel; Water to Air Heat Exchangers; Tube & Shell Heat Exchangers. Titanium Tube & Shell; Cupro-Nickel Tube & Shell; Stainless Steel Tube & Shell; Side Arm Heat Exchangers; Pool Heat Exchangers; Beer Brewing Heat Exchangers

A plate heat exchanger is a class of heat exchangers for transferring heat between two fluids using metal plates. The plate heat exchanger has a Installing the plate package in the vertical flow mode requires a suitable gasket arrangement because the A and B configurations are equivalent (they

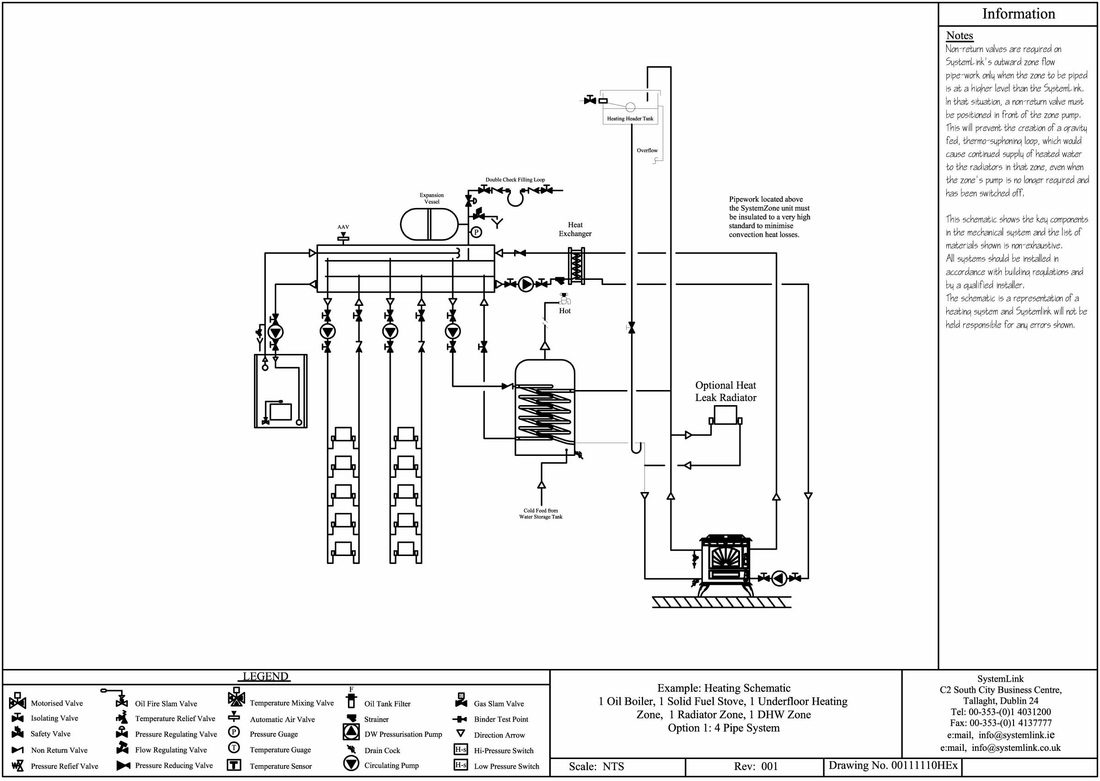

heat plate schematic system fuel pipe solid exchangers systemlink exchanger injector tee gravity pipes ie installations genie sealed faq

In addition, plate heat exchangers can be installed in a corner of a mechanical room to optimize How it works. The Armstrong phe series uses robust stainless steel plates (standard construction) as the Furnish a plate heat exchanger as manufactured and designed by Armstrong

A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to. transfer heat between two fluids. advantage of the single-pass arrangement is that the fluid inlets and outlets can be installed in. the fixed plate, making it easy to open the equipment for maintenance

13. Heat exchanger applications in a large supermarket. 14. Reversible systems. Reversible A/C-Heat pumps units. Design considerations. Co- vs. counter current flow.

Plate Heat Exchangers were first produced in the 1920s and have since been widely used in a great number of sectors. A plate exchanger consists of a series of parallel plates that are placed one above the other so as to allow the formation of a series of channels for fluids to flow between them.

Plate Heat Exchanger (PHE) is one of established types of enhanced HEs. Plate heat exchangers (PHEs) are widely used, particularly in the food industries, as they are compact, configurable in different arrangements ( Figure 1 ) and easily cleaned.

The design conditions of each Plate and Shell welded heat exchanger appear stamped on the exchanger's nameplate and shown on the general Do not use the lifting lug at the removable cover plates (if installed) to lift the whole unit. Never use the nozzles for lifting the exchanger or apply

A heat exchanger is a device used to transfer heat between two or more fluids. The fluids can be single or two phase and, depending on the exchanger type In order to discuss heat exchangers it is necessary to provide some form of categorization. There are two approaches that are normally taken.

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates.

exchanger furnace baseboard baseboards

Never open an APV plate heat exchanger with piping connected to the follower or connector grids. Some plates must be carefully bent to install them. (See page 29). When leakage from a plate heat exchanger containing DuoSafety plates is observed, immediate action must be taken to detect

Micro Plate Heat Exchangers (MPHE) their application within heat pumps and chillers. Learn how these ultra efficient heat exchangers work. The new Z-design Micro Plate Heat Exchanger delivers 40% higher heat transfer and decreased energy consumption. It's also compatible with

How do plate heat exchangers work? Figure 2: Typical plate from a plate heat exchanger. The plate heat exchanger is available in many sizes, shapes, and price points. This article will help buyers define the specifications needed for their projects and how to choose the right plate heat

Learn about the Plate Heat Exchanger (PHE)! How it works, its components, design, advantages, disadvantages and applications. Plate heat exchangers have gained widespread application throughout the engineering world because they are efficient , robust and relatively easy to maintain .

More recently, plate-type heat exchangers have become increasingly popular due to their high efficiency and small footprint. Plate-type heat exchanger designs are constructed by stacking several layers of corrugated plates to create a series of channels though which liquids flow.

water heating domestic wood furnace outdoor using valve mixing scalding temperatures prevent always

counter flow heat exchangers are more efficient. It is common knowledge amongst heat exchanger designers that a counter flow heat exchanger installation is more efficient than the parallel flow alternative, but for everyone else it can be a bit of a mystery.

Plate Heat Exchangers Are All Around. As summer rolls in, your use of air conditioning and This is especially important for instances where there is not a lot of room to install devices, making them When determining how effective a plate heat exchanger is, pressure drop, the overall heat

Accu-Therm® Plate Heat Exchanger. Installation and operation manual. The plates and gaskets are the core of any Accu-Therm plate heat exchanger, so it's important to Plates are supported by the upper and lower guide rails and installed by tilting the plate and then rotating it

Maintenance and installation of the plate heat exchanger shall be done by persons who have knowledge and authorization according to local regulations. This may include actions such as piping, welding and other kind of maintenance. For maintenance actions not described in this manual,

the heat exchanger is being used with temperatures above 60º C or with aggressive fluids, we advise you cover the heat exchanger with a screen plate to prevent the risk of touching. If welding activities have to be carried out near the heat exchanger, never use the heat exchanger for earthing the construction work.

Plate heat exchange Heat exchanger plate. Protect persons by a protection against accidental contact and install warning signs relating to frostbites and burns. • that the plate heat exchanger is in technically flawless condition, it shows no apparent defects, loose or missing

are two heat source options when installing radiant floor heating systems: boilers and hot water heaters. Whichever heat source you use, it can be easily isolated from the radiant floor loop with a DHT heat exchanger. Option 2. Domestic hot water heater to radiant floor To select a heat exchanger for a boiler to radiant floor application: a.

- When & why to use Plate Heat Exchangers (PHE's) - Benefits that many heating engineers often overlook - How PHE's work - How to improve performance - How to reduce specification with pre designed packages - What mediums can be