How To Improve Warehouse Safety. The Cost of Warehouse Accidents. Why Is Safety Important In A Warehouse? Warehouses are notorious for being one of the most dangerous workplace environments. Workers are often seriously injured and some even die as a result of

There are plenty of ways to improve warehouse and worker safety with both trusted and new technologies. If you don't have any of the following safety measures in place, implementing them may make it easier to keep across all aspects of warehouse safety, and even day-to-day

Warehouse Supervisors, Health & Safety Officers and all warehouse employees need to work together to reduce the risks on a day-to-day You might need to consider how you will communicate site rules with visiting drivers who speak very little English or have a limited understanding of

lighting industrial led warehouse t8 retrofit

No matter how you look at it, a warehouse can be a perilous place to work. Even though the warehouse can easily become a dangerous place to be, there are still some actions that one can take to drastically improve the safety of the warehouses.

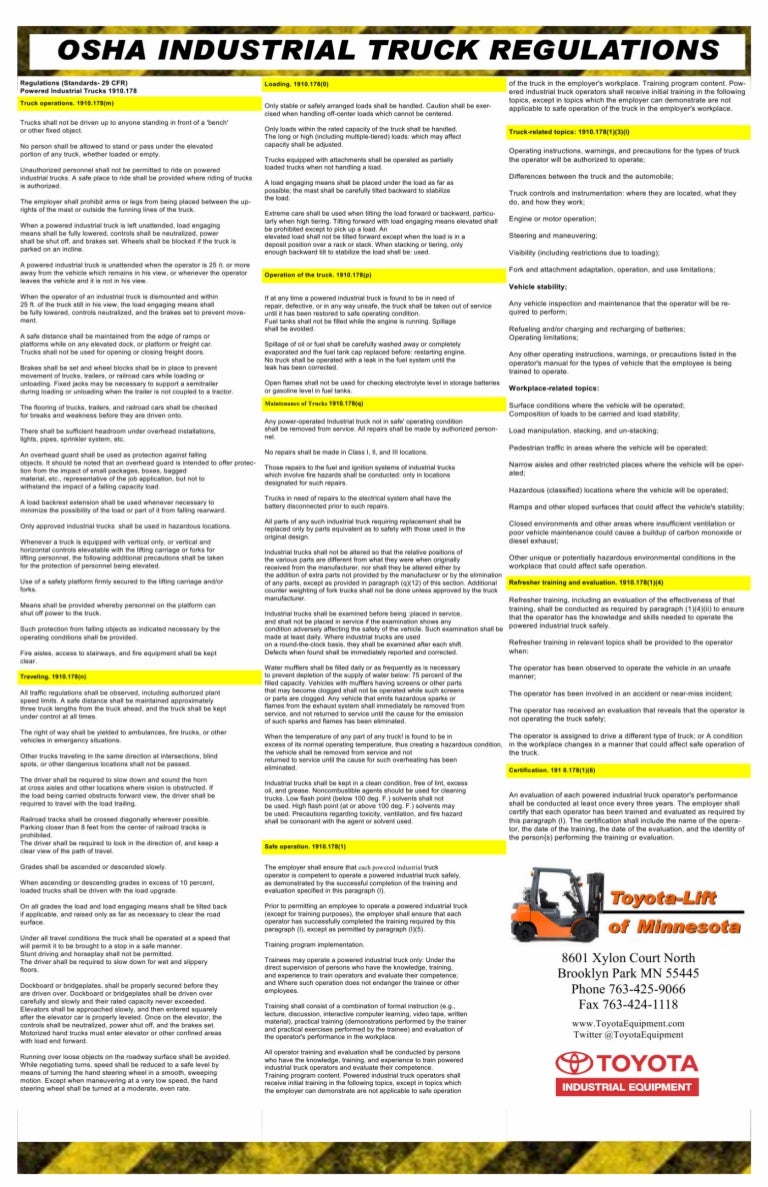

forklift osha

Hence, warehouse maintenance procedures should be given as much priority as other daily operations. This will not only improve operational efficiency, but it will also reduce the chance of accidents and their associated Conduct safety drills, such as fire and evacuation drills, regularly.

You might even consider posting warehouse safety tips and lists like this, as a constant reminder to your employees to practice safety above everything else. Posters could describe proper lifting techniques, how to handle hazardous materials, how to operate specific machines, etc.

In warehouses there are a number of hazards that can cause your staff serious injury. To help, we have put together 5 tips on how to improve warehouse With this in mind, we have put together 5 tips to help you achieve optimum warehouse safety. You certainly don't want to end up like this

How Can Technology Make Warehouses Safer? Significant technological advancements in the recent decades means that having a computer system installed in a You can also check out the video below which outlines our efforts to create a solution that specifically improves warehouse safety.

Our Warehouse Safety Training educates learners on how your warehouse may put workers at risk and what you can do to control exposure, including hazards posed by vehicles, manual Warehouse Safety Tips. The sections below cover common warehouse hazards you should diligently manage.

rack steel storage bar tube systems shelving industrial advantages racks metal stainless material warehouse system pallet industries coil stackable king

Warehouse safety can be complex, but with a bit of planning, some training, and clear demarcations, you can significantly reduce risks to Here are ten tips for effectively improving safety in your warehouses. (Find out How to Design Safe Loading Docks and Warehouses for Lift Truck Drivers).

This weeks blogs looks at 12 safety ideas to improve warehouse safety. To ensure the highest level of warehouse safety around these dangerous sources of ignition it is imperative all potential sources of fire are kept far away.

warehouse tidy storeplan

expandable barriers expanding barrier gates nz ullrich factory aluminium visitors zone footprint minimal lightweight effective closed less than easy

— How to Improve the Warehouse Receiving Process, Floship; Twitter: @floship. 17. Identify your KPIs. "A warehouse management solution can help you to track the right Post signs in areas where only warehouse personnel are allowed and install physical barriers (safety upgrades) in key areas.

DIscover key warehouse security measures and how to improve safety at your facility! What does warehouse security have to do with preventing cargo theft/shrinkage? How can you create a high-security warehouse?

You are required by law to have appropriate safety measures in place in your warehouse. These measures not only protect your business but your employees too. Training your staff on how to use machines and equipment could help to reduce the chance of injury. This is even more paramount

Looking to improve warehouse safety in your facility? Warehouse Storage Rack Safety Netting - Less expensive than the pallet load stop beam, this form of warehouse safety netting has the added advantage of visibility, so workers can see the products being stored in the bay.

Featured Topics Why is Warehouse Safety Important? How to Improve Warehouse Safety Warehouse safety is a set of regulatory guidelines and industry best practices to

Warehouse professionals, therefore, must know exactly how to keep operations running efficiently. With the right mix of best practices, your company To help you improve your warehouse operations, we have rounded up 51 of the top tips from around the industry. The following best practices

Warehouse safety starts with proper training for operators, but sometimes that's not enough. Dixie Warehouse Solutions features a collision avoidance Dixie Warehouse Solutions can't help you with every one of these safety issues, but we can help a lot. Call now to learn how we can make

You can improve warehouse safety by customizing your safety strategy that meets your warehouse safety needs. How can 3PLs implement warehouse safety? 3PLs like ShipBob provide warehousing and distribution services, along with fulfillment solutions.

Learn how to improve safety in your industrial workplace today. Are you looking to supplement your warehouse safety training and manufacturing safety tips with safe storage options? Look no further than our industrial storage products.

March 22 2019 - Implementing a warehouse health and safety plan is an integral part of ensuring employee wellbeing, and getting it right is key ensuring a smooth operation. In this article, I'm going to share some top tips to help improve your warehouse safety.

10 Warehouse Safety Tips. Warehouses are required to implement a safety plan, but safety doesn't end with implementation. It's also paramount that the execution of It is essential to assess how much weight a rack can endure and how the materials should be stacked to achieve effective distribution.

Improving warehouse safety. Even during their quietist periods warehouses can be busy, lively places. However, it is important to assess your warehouse during a range of different periods throughout the year, to build a clearer understanding of how to best improve warehouse safety.

OSHA's Warehouse Safety Requirements. Every workplace carries health and safety risks. It's why regulatory bodies and workplace laws exist in the Lockout and tagout procedural problems: Effective protocol on how to safely power down any electric, pneumatic, hydraulic or chemical

1. How to Improve Warehouse Productivity. Look at the jobs your workers do in your facility. Additionally, you may improve loyalty and productivity through increasing safety in your workplace. 3. How to Reduce Warehouse Costs. The cost of running your facility includes labor and operations.

warehouse disorganized inefficient company wpss storage space efficiency shelving tips 1917 1045 courtesy

Safety in a warehouse environment is imperative. Improvement measures should be undertaken regularly in Health and safety, no matter how much you think you have it covered, is something With that in mind, what are the easiest ways to improve the overall safety of your warehouse space?

segmentation logistica beheren channels procurement santova multigiro demand peoplesafe zyro timberlake ultrashine logistics vragen

warehouse dividers curtain curtains divider industrial storage cold walls plastic commercial panels partitions vinyl waste noise reduce insulated costly separating

Developing and improving security systems for a warehouse can be intimidating. You need to keep a lot of things in mind from theft prevention, fire, and safety, surveillance, access to data security, environmental monitoring. You need to be very careful while improving your safety measures.

Warehouse safety is changing quickly. Learn practical ways to champion safety in your Warehouses across the country are facing new and unusual safety challenges — but warehouse In this guide, we'll look at practical ways to prioritize and improve your warehouse safety program.

Here are 10 ways to improve warehouse safety. Use these safety tips to improve working conditions and efficiency in your operation. Inspect forklifts and their safety features and repair immediately when faults are discovered. Inspect often for rack damage and repair immediately on discovery.

Warehouses are highly busy environments filled with heavy equipment, large boxes, heights, and forklifts. With all of these factors at play, maintaining a safe workplace is essential. Fortunately there are a number of steps that can be taken to further improve warehouse safety.