Overall Equipment Effectiveness (OEE) is a measure of machine potential that brings visibility to Learn more: Why You Need a Digital Champion in Manufacturing. 2. Automate data collection and See how TMI used Evocon and cross-functional daily meetings to improve OEE by 30% or

OEE (Overall Equipment Effectiveness) is the global standard for measuring manufacturing productivity. OEE can be a powerful metric to help improve By measuring OEE, manufacturers will gain important knowledge on how to systematically improve their business processes.

TCU and overall equipment efficiency (OEE). There are many reasons for a low TCU. These can be described using OEE indices. OEE 3 describes the total efficiency of the manufacturing site taking loss 2-4 into consideration. This is typically how a site manager's performance is measured.

machine downtime machinemetrics monitoring tracking manufacturing operator cnc software oee animated floor lean categorizing data categorize recent utilization why

Three methodologies for improving OEE in manufacturing. The three most popular manufacturing improvement methodologies are Lean Manufacturing This page introduces a simple and universal methodology for driving any improvement activity and shows you how to apply it to OEE.

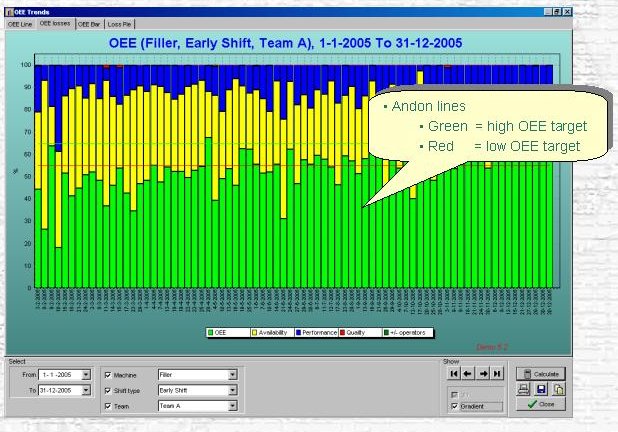

Overall equipment effectiveness has become one of the most popular manufacturing metrics in recent years. Plant and operations managers use OEE to However it does not provide the user with any information about the source of the losses, leaving a lot of guesswork as to how to

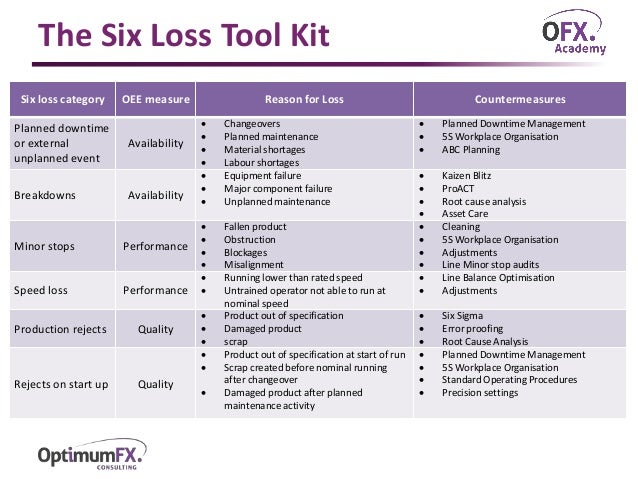

How to improve OEE. OEE highlights the "major losses" in the manufacturing process for focused improvement. It can then be used to measure the effect of efforts or initiatives To improve OEE you need to focus on the three elements of the OEE formula - Availability, Performance and Quality.

Overall equipment efficiency (OEE) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared to its full potential, during the periods when it is scheduled to run. It identifies the percentage of manufacturing time that is truly productive.

BI for Manufacturing: Overall Equipment Effectiveness. What is Overall Equipment Effectiveness (OEE)? OEE is a measure of the throughput of acceptable quality units over the scheduled operating time of a piece of equipment, cell, line or plant.

How to Calculate Overall Equipment Effectiveness. A factory's OEE score is made up of three component KPIs: availability, performance, and quality. Make Matics Part of Your OEE Improvement Plan. Improving your real-time OEE is imperative to your manufacturing plant's long-term success.

1 Improving productivity in manufacturing operations. How to improve operational efficiency in manufacturing. Keeping senior managers informed. Business Process Automation Next Steps. For more information on how to improve operational efficiency in manufacturing, download

Overall equipment effectiveness is a concept you've likely run into before. Here's a guide to OEE-based QA in the electronics manufacturing industry. How can you use this score to do so? Why is OEE useful in electronics manufacturing quality assurance? 1. Tracks roadblocks in real-time.

Overall Equipment Effectiveness (OEE) is a manufacturing metric that takes into account the separate processes of a production line. If a manufacturer has to produce a range of batch sizes and types, then the OEE of a decoupled system will be much improved, when compared with

Out of all, Overall Equipment Effectiveness (OEE) is widely recommended for its ability to provide direct insights on machine utilization & effectiveness. Let's find out what Overall equipment efficiency is, how it is calculated and how it helps in improving manufacturing process,

Improve your overall equipment effectiveness (OEE) in manufacturers with digital manufacturing solutions for limiting CAPEX, boosting front-line worker productivity, and more. overall equipment effectiveness. Find New Ways to Improve OEE.

oee dashboard member root cause analysis

Overall Equipment Effectiveness (OEE) really provides three simultaneous measurements of how well manufacturing capital equipment is performing. It helps manufacturers understand how to improve their products and reduce future quality control issues.

oee

OEE is the Overall Equipment Effectiveness of a defined production process during the defined operative period or mode in which all activities A proven technique in manufacturing comes to packaging. Typically OEE is confined to the production or packaging process, but does not need to be.

Overall Equipment Effectiveness, more likely known as an OEE calculation, is a way for Why OEE Calculation is Important in Manufacturing. It's pivotal to understand the OEE Identifying ways to improve OEE can be challenging because the human eye can process limited data at one time.

How to leverage OEE. Overall equipment effectiveness is an indicator of a manufacturing process's efficiency. Once you've calculated it OEE as a benchmark. When comparing OEEs, there's always going to be some variation based on the type of manufacturing, but here are some general numbers.

How to improve OEE ? is a most valuable question nowadays, because all companies are trying to reduce the manufacturing cost and the improvement in OEE gives a good result for that. Before we start I recommend you to the article of OEE.

oee software toolkit trends info

Complete Guide to Calculating & Improving Overall Equipment Effectiveness. Measuring the output always matters and in manufacturing, it is even How to improve OEE. OEE case study. Let's get started with OEE. Overall equipment effectiveness is a key metric (includes a combination of a

lean boards performance visual management metrics process manufacturing improvement presentations junk michelbaudin chart operations michel baudin 1945

oee dashboard analysis member root cause form

Introduction Learn how to measure and improve OEE with smart manufacturing solutions! There are several ways to improve OEE, an important business metric. You probably know a thing or two about OEE and what stands behind it, but let's take a moment to revise some basics.

Benefits of OEE in Manufacturing. Ensures you use existing equipment to its fullest capacity Improves the scalability of your production line. How to Make Performance Gains Using OEE. With this information, you can then allocate a budget to improve OEE and achieve your overall

manufacturing iot internet things industrial network visibility iiot operational trends iqms wireless arm influence higher lean roadmap improved interoperability redefining

Learn how to calculate and use Overall Equipment Effectiveness to improve your production process [OEE calculation examples included]. Overall equipment effectiveness takes your manufacturing program from good to great - so you need to be starting from "good." This means

The OEE formula: How to calculate OEE How to improve OEE and your maintenance operation Overall equipment effectiveness (OEE) is like a performance review for assets.

delmia

Overall equipment effectiveness (OEE) is a quantitative measure that. has been growingly considered and accepted in manufacturing processes how to improve. The present case talk about how the OEE of equipment employed in injection. moulding process was improved by adapting

In this video, Walker Reynolds explains how to implement OEE in your manufacturing plant. This is a follow-up video to Why you need to calculate OEE if

Overall equipment efficiency or effectiveness (OEE) is a hierarchy of metrics proposed by Seiichi Nakajima [3] OEE is not only a metric, but it also provides a framework to improve the process. So OEE quantifies how well a manufacturing unit performs relative to its designed capacity, during

OEE and comparable manufacturing metrics are also fueling the development of business intelligence software and advanced analytics, which includes the next Important insights can be gained on how to systematically improve the manufacturing process by measuring OEE and the underlying losses.

oee equipment dashboard production effectiveness dashboards reports overall produce losses calculated

In manufacturing terminology, OEE stands for Overall Equipment Efficiency. Actionable Strategies to Improve OEE. Video Case Study: How Avalign Technologies Increased OEE by 30%. Lean Manufacturing. This is actually the birthplace of OEE.

Understanding Overall Equipment Effectiveness in Reliable Plant describes OEE in greater detail and explains how operations, maintenance, quality, and Manufacturing organizations will continue to pursue improvements in OEE. As evinced above, IoT can deliver significant, quantifiable improvements.