oee losses

losses six

gemba oee maximising minimising output

oee

factory inside manufacturing

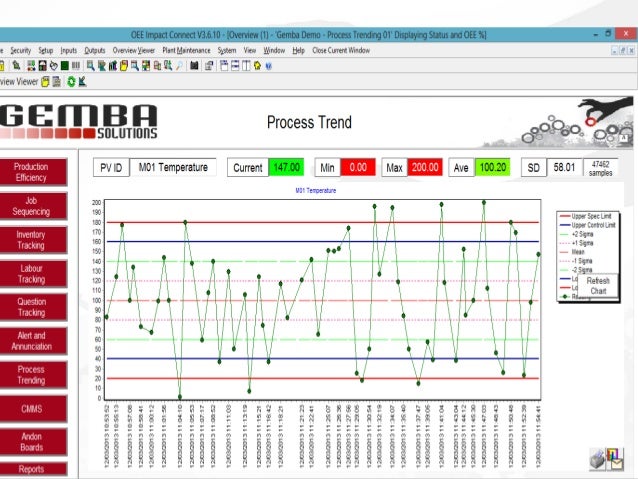

Reading Time: 5 mins Prioritize your manufacturing assets. Focus your OEE assessment first on those machines …Gather real-time IIoT data. Machine histories can be useful and informative, but if that’s all …Understand the components of OEE. In improving OEE, it pays to dig into the values that …Optimize the OEE formula. OEE should not mean the same thing for all production …Perform smart maintenance. Once your your real-time machine condition-monitoring is in …Improve asset environments. For most of your production machinery, environmental …Connect OEE and machine condition monitoring with business systems. When OEE and …See full list on

oee

oee effectiveness verliezen afkomstig

example: Brief and educate team members (so everyone is on the same page) Task-out the improvement cycle (fill in details as needed) Touch base with scheduling (to allocate time to work on the equipment) Purchase any needed materials …

5s tpm automotive oee company supply workshop within before lean asset condition

oee calculating improving calculation

oee dashboard qlikview analysis data analytics

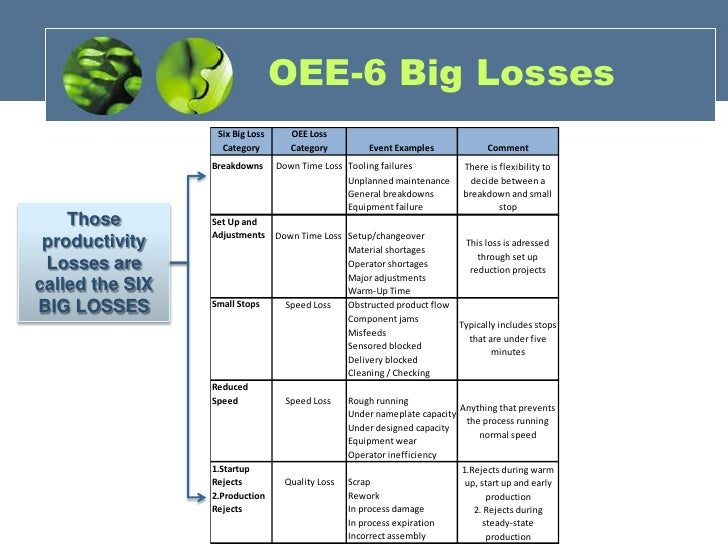

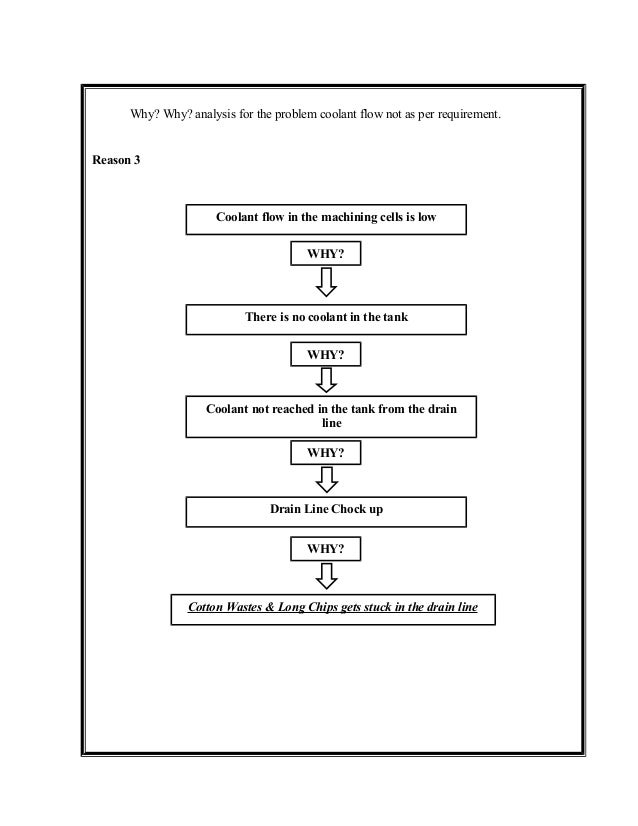

Improve OEE by assigning a digital champion. Sometimes, a company may struggle to …Automate data collection and reporting. The next best practice for improving OEE is to …Visualize and display real-time OEE on the shop floor. Visualization dramatically improves …Make sure all production stops are commented. Once you have an automated OEE software …Implement cross-functional daily review and discussion sessions. The point of this best …Start eliminating the Six Big Losses to improve OEE. The Six Big Losses make up the basis …Utilize Root Cause Analysis. Once OEE brings visibility to your six big losses, it is time to …See full list on

floor factory management panasonic visualize oee entire industrial visualizing better connects working each area

production management floor process grey improvement control increase throughput automated

to improve OEE? Use Variable Frequency Drives (VFDs). One way to improve OEE is to use variable frequency drives (VFDs) instead Use Electric Actuators. Another way OEE can be improved is to use electric actuators rather than hydraulic or Spot Problems with Machine Vision. ...

Use OEE to improve collaboration. Overall Equipment Effectiveness is an excellent tool for …Set realistic OEE objectives. Know what your APM challenges are and figure out your own …Use data to your advantage. Ideally, you would gather data from all your IT/ OT systems and …Prioritize and focus. Which assets are critical for reliable performance and quality standards? …Give preventive maintenance a boost. Preventing failure of your assets (especially your …See full list on