case study) and how this implementation of 5s makes direct effects in increase cleaning, saving time, effort and money, reduce defects and making a growth - Analytical method: by analyze the results of implementing 5s in the 2 warehouses and. making awareness of 5s & Kaizen in the workplace

The implementation was carried out in Transval Groups's Customer's warehouse. The entire project itself, was divided into nine different sub-groups. This seminar helped the researcher to understand the funda-mental meaning of 5S and how to implement this system into the warehouse environ-ment.

10, 2016 · 8) Improve Warehouse staffs' morale. Let’s look the 5S steps one by one for implementing 5S in the Warehouse: Sort or Seiri – In organizing your workplace and home, the first thing to do is to ...

Products' free 5S standard color code guide shows a warehouse with 5S colors, patterns, and typical visual communication. Use reflective tape on posts, loading docks, or company vehicles to improve visibility. Keep workers upright in slippery conditions anti-slip tape. Available in 5S colors, it'll help with warehouse organization and safety.

How. Details: Implementing the 5S methodology is all about sustaining the positive changes that it brings along. How. Details: 5S in the work place is one of the primary tools that can be implemented in an organization as a starting point to change the culture of an organization to a

How do you implement 5S in a warehouse environment? Implementing the 5S method means cleaning up and organizing the workplace in its existing configuration. It typically is the first lean method that organizations implement.

A 5S implementation helps to define the first rules to eliminate waste and maintain an efficient, safe, and clean work environment. The 5S methodology is easy for everyone to start using. It doesn't require any technical analysis and can be implemented globally in all types of companies,

Designing a new warehouse layout can be a complex process, but with these tips, you'll be able to design for ease and efficiency. Setting up a new layout is a massive undertaking, and no matter what, the best way to implement a redesign of your warehouse is to have a game plan.

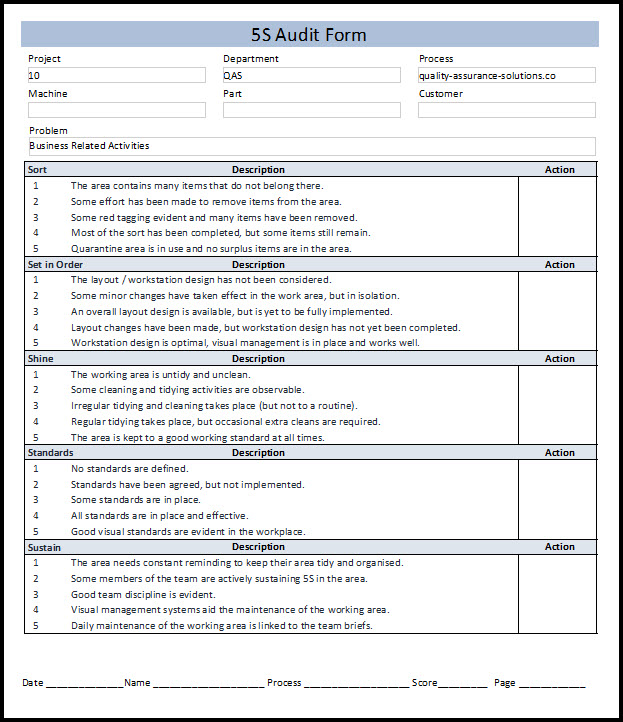

5s audit assurance iso 9001 forms lean software management sigma six streamliner sample plan warehouse risk logistics

8 Ideas For Warehouse Organization You Can Implement Now. Repeat after us, "A Messy Warehouse Means a Messy Business." There's little point if your star sales reps are pulling in orders only to see them picked and packed incorrectly or goods are received incorrectly.

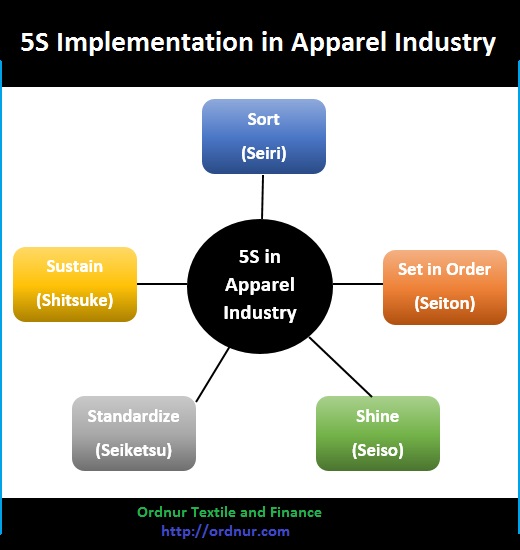

5s sewing section industry apparel implementation garment system textile housekeeping procedure ordnur follow tag need sop operating implementing

5s kaizen lean process event banner nutshell management simple visuals methodology classroom poster map mind steps sigma fast improvement manufacturing

To implement a basic implementation with a pre-existing Oracle Database 10g Release. Alternatively, you can use the security interface in Warehouse Builder to design your own security policy. In either of these two cases, ensure that repository database has the Advanced

How to Implement 5S in an Organization Creative Safety. The 5S implementation team should consist of people from all levels of the organization, including the following: Senior Management - Having buy-in from the upper-level management teams is essential. how to implement 5s program.

Follow these steps for implementing a data warehouse In many ways, a data warehouse is similar to a regular warehouse in that they are both all about processes - how things arrive in, how the items are stored and ordered, and how to process fulfillment requests as quickly as possible.

5s warehouse methodology systems storage

implementation; • Personal involvement in implementation of 5S; • Creating tangible and intangible rewards and. • Selected 6 enterprises provided advisory support to implement 5S and QCS by International Consultant and TCC attached to each enterprise.

Warehouse Management Proper warehouse management can dramatically improve both efficiency and safety. The 5S methodology originated in Japan and was first implemented by the Toyota Motor How to Get Started. Starting any project that involves the potential for large changes can

The 5S system is a lean methodology that improves workplace efficiency and eliminates waste. This article reviews the five steps, common uses Everyone should pay attention to the overall cleanliness of the workplace, being willing to pick up trash and so on. But for 5S to give the best results,

5s system came out of Asia a few years ago, and it’s been a great system for many Wisconsin warehouses. If you’d like to learn more about the 5s system, order pallet racks for your warehouse, or ask one of our warehouse consultants to come to your location to help implement the 5s system, give us a call. Our team would love to work with ...

Warehouse systems optimize warehouse space thanks to implementing automated guided vehicles that are responsible for product retrieval and storage. No matter how advanced the technology is, there can be no automation in warehousing operations without hardware and software to control it.

warehouse safety unsafe conditions safe workers 5s checklist methodology forklift wastes eliminate rules keep them deadly ishn wherever brakes putting

SORT. Warehouse managers often fall into the trap of using established …SET. This step is sometimes interpreted as “straighten” or “streamline.” …SHINE. If you walk into a Lean warehouse, the results of this step will likely …STANDARDIZE. Standardizing is the hallmark of the Lean methodology. A …SUSTAIN. The final step to any successful organization methodology is the …See full list on Reading Time: 8 mins

5s visual management lean manufacturing warehouse implement floor before kaizen improvement pallet order cisco eagle standard industrial safety marking seiton

How do we implement a 5-S program? Step 1 - Align the organization to adopt 5-S. Management and hourly associates participate. Implementation of 5S Methodology in a Manufacturing Industry. This paper highlight s the step by step implementation guideline required for successful exercise of 5t

05, 2021 · How To Implement 5s System In A Warehouse Continuous Improvement? 4 minute read; Clayborne. December 5, 2021; 0 Shares 0. 0. 0. 0 Shares 0. 0. 0. 0. The results of good processes are good. Take a moment to learn more about the current situation. Don’t forget to use facts when dealing with data.

Serving as your guide to proper 5S and visual workplace implementation, this brief yet detailed playbook can be used as ... Step-by-Step Implementation f. y g. 5S. Textbook &. Instructors' manual. August, 2006. Japan Productivity Center for So ...

3. Table of contents Part 1 Introduction Part 2 How to implement Part 3 How to motivate people to practice 5S. 30. Set in Order (implementation phase) Create a well ordered, visually instructive work place Target Outcome A workplace that is visually instructive and is the source of minimal waste

lean warehouse principles thinking warehousing distribution learn shmula center management

warehouse skills worker

Implementing warehouse picking improvements are one of the most effective ways to optimize the supply chain. Depending on the warehouse size Warehouse picking is the step that occurs before products are packaged and shipped out to their destination. 2. How to do picking in warehouses?

How to Build a Data Warehouse from Scratch: Approaches, Plan, Software, and Costs. Duration: from 2 months. Data warehouse platform customization. Configuring data security software and implementing data security policies (applying data security policies to data at the row, column,

06, 2021 · How Do You Implement Warehousing? Make a plan for your warehouse. Make sure the warehouse is properly arranged. Make sure you plan ahead for the different demands. Adaptability is key. Bin locations should be used. Label your products with labels. Cross docking should be implemented. Make sure your staff is trained effectively.

do you implement 5S in a warehouse environment? ! First make Zone and sub zones Appoint Zonal leader sub zonal leader Make 5s training Material Do training Prepare Red Tags And Red tag area Segregate the items only needed items to kept Make list of Usage Frequency of Items kept in Racks With ...

Step by Step – The Lean Warehouse 2018 5S STEP BY STEP STEP 1-SORT Original Japanese word: Seiri Remove the unnecessary – Keeping only what is used and red tag the rest The first step of 5S focuses on eliminating unnecessary items from the workplace. This will help eliminate problems such as: Tools & materials slowing workflow

How to implement shine. STEP 1: DETERMINE SHINE TARGETS Warehouse items-equipment-space. after a Companywide 5S implementation campaign At the end of the day pileds of unneeded items are left from the day's production and lie scattered around the production

start the 5S: Step-by-Step Implementation, each phase must be thoroughly analysed and addressed using the P-D-C-A Cycle and 5W2H approach as follows: Provide training and education for everyone. Form 5S Council. Set-up 5S Zones. Determine 5S objectives, goals and implementation phases. Plan 5S action plan and 5S Launch. DO PLAN Set in Order: Shine: …File Size: 1MBPage Count: 67Missing: warehouseMust include: warehouse

Q: 5-S Guidelines Review the 5-S Guidelines provided in Chapter 8. Using your desktop, a coffee table, or other small area, attempt to "5-S" that area. In 200-250 words, discuss some of the challenges you faced when trying to implement 5-S and ways you overcame them.

5s warehouse storage methodology systems racking thistle implement recognised cube approach max been

Nov 17, 2016 · The first thing needed to implement 5S in an organization is a team of people to lead the effort. The 5S implementation team should consist of people from all levels of the organization, including the following: Senior Management - Having buy-in from the upper-level management

warehouse 5s pre practices clearly idea bad

How to initiate 5S implementation. The 5S approach outlined in this guidebook is a simple and systematic methodology which can be introduced Plans describing implementation of the 5S phases must be prepared and released during the 5S declaration. The most common mistake

Data warehousing is the process of collating data from multiple sources in an organization and store it in one place for further analysis, reporting and business decision making. Typically, organizations will have a transactional database that contains information on all day to day activities.

How to Avoid the Most Common Warehouse Safety Hazards. 5-S is not simply eliminating toolboxes and cleaning up. While the concepts are easy to understand, most companies have not implemented them.

5. Implement Warehouse Management Software. To improve efficiency, consider using a warehouse management software (WMS). HashMicro's WMS does not only help you improve your order picking productivity, but also oversees your inventory movement and helps speed up

How to Determine Candidates for Using a Bitmap Index. Using Bitmap Join Indexes in Data Warehouses. When Not to Implement Parallel Execution. Automatic Degree of Parallelism and Statement Queuing. About In-Memory Parallel Execution in Data Warehouses.

03, 2022 · Build organizational commitment so that 5S becomes one of your organizational values so that everyone develops 5S as a habit. Integrate the 5S methodology into the performance management system. Step 3: The Action Plan. You can start implementing 5S by providing training to your staff to understand the Reading Time: 7 minsMissing: warehouseMust include: warehouse

5s industry implementation apparel garment textile english japanese visual why basic implement workplace method ordnur finance difference tag

Find out what are 5s in the warehousing and how you can use them to efficiently manage your warehouse. What is 5s in the warehouse? Implement the barcoding scheme not only for product positioning but also for aisles, putting barcodes onto shelf tags or labeling tape on floors.

5S methodology. 5S resource corner at Scanfil Poland factory in Sieradz. 5S is a workplace organization method that uses a list of five Japanese The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how