The furnace is used to heat treat D2 and A2 steel under air atmosphere and is part of Lucifer's standard, general purpose Series 7000 box furnace lines. The September issue of Fabricating & Metalworking features a cover story entitled: "Seeing Double, How Smart Factories Use Digital Twins."

rat ontario copper d2

steel chart heat heated treating range temp basic

how to heat treat D2 Steel. 24:16. Heat Treat W1 Tool Steel without an Oven: Making a Hardened Bolt. 14:00. Heat treating 4140 Alloy Steel - The basics on hardening and tempering.

I am having a little bit of a hard time heat treating W2 steel I got this spring. First try 1550 1 min soak in oil no luck blade did not harden at all 2nd try 1550 1 min soak right into water blade blade is still soft.

steel dc53 titus die

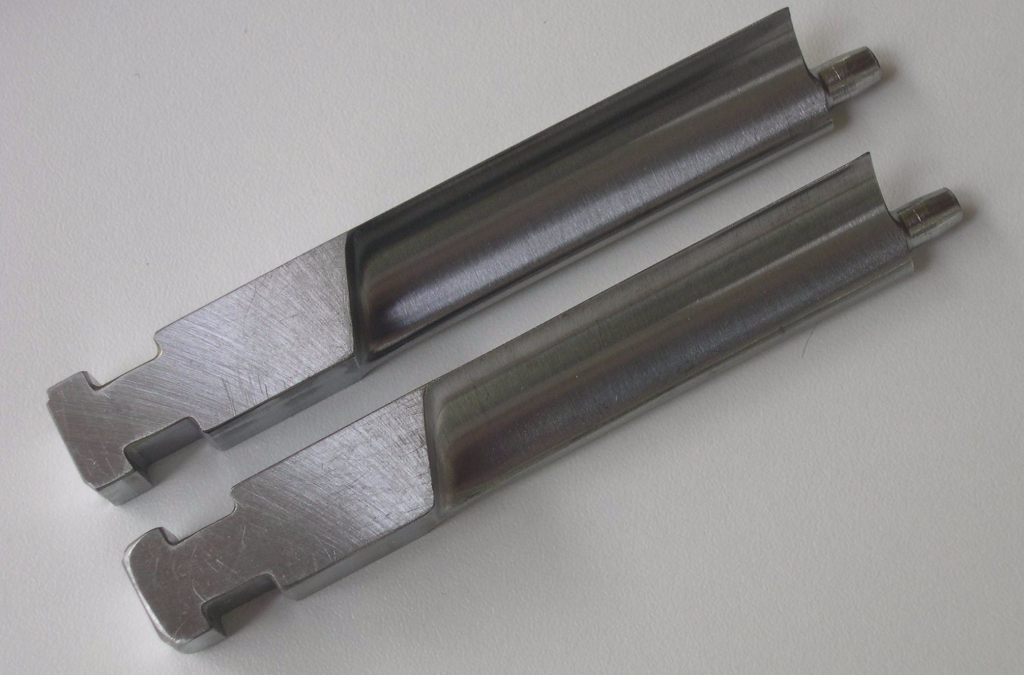

heat turbine treating blades received parts furnace

I'm conflicted about the heat treat time for d2. Most of the info I found says to heat to 1850f for 20-30 minutes. D2 heat treat ? Thread starter Shipshores. Start date May 8, 2016. Stainless steel and air hardening steels are used as-is. Normalization and annealing are not in the normal skill set

How to Heat-Treat D2 Steel eHow. This complex mixture makes proper heat treatment of AISI D2 more complex than the heat treatment of other Any D2 Heat Treat Experts. D2 is a high chrome, high carbon, air hardening tool steel, and as such will decarborize unless heated in a vacuum

Heat treatment on low carbon steel is to improve ductility, to improve toughness, strength, hardness and tensile strength and to relive internal stress developed in the material. Here basically the experiment of harness and ultimate tensile strength is done to get idea about heat treated low

Heat Treating of Alloy Steels. Case Hardening of Steel. Flame and Induction Hardening. It is difcult to imagine how our lives would be changed if the prop-erties of metals could not be altered in a variety of ways through the use of heat treatment.

Watch the video explanation about how to heat treat D2 Steel Online, article, story, explanation, suggestion, youtube. some hardness and increases now in the. 11:07. sense of d2 it's a little bit different.

At first, I was not sure of what to do and how to do it with regards to nanoindentation and material characterization but through his mentorship I was able to wade through the storms of countless lonely nights in the Microstructure of D2 "Heat treated and water quenched" tool steel sample [20μm] ...

Heat Treating Blades at Home Accurately Aiming for Minimal Scale and Decarburization. Bushcraft Knife Making How to make Handmade Knives Tutorial and Heat Treat Steel.

How to Heat Treat Stainless Steel for Knife Making. Heat the steel through to 1,560 degree Fahrenheit using a forge or heat-treat oven . Once thoroughly heated, slowly cool in the furnace by dropping the temperature 20 degrees per hour to 1,200 the steel slowly over

Using a torch, heat your steel item until it glows red-hot. Do this very close to the Webber grill. When the metal is glowing red hot use your tongs to immediately transfer it to the burning coals of the Bar-B-Q. Re-heat your steel once again, but this time only heat it until it turns a brilliant shade of blue.

Warren used two different starting microstructures with his heat treatments and sourced steel from two different places. I have used this heat treat on about 30 knives now, most of them fine edged very hard use bushcraft and survival knives. it is a very time consuming process compared

This video shows the steps and materials needed to heat treat D2 steel.

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical.

Heat treatment - as applied to steel - can be defined as the application of heat to change a characteristic or condition of the steel. Heat treatment is the process of heating up to temperature, soaking at that temperature and then cooling down from the temperature.

Hardness and Hardenability (Part Two) Fundamentals of Heat Treating: Ideal Diameter Stainless Steel Part Two: Heat Treatment Techniques Tool Steel Oil Quenching Oil Quenching Part One: How to Interpret Cooling Curves Oil Quenching Part Two: What is Your Quench Oil Analysis Telling You?

heat steel d2 treat

• Heat treatment simply is a combination of heating and cooling operations, timed and applied to a metal or alloy in the solid state in a way that, will produce desired properties. • All basic heat-treating processes for steel involve the transformation of austenite. • By varying the manner in which,

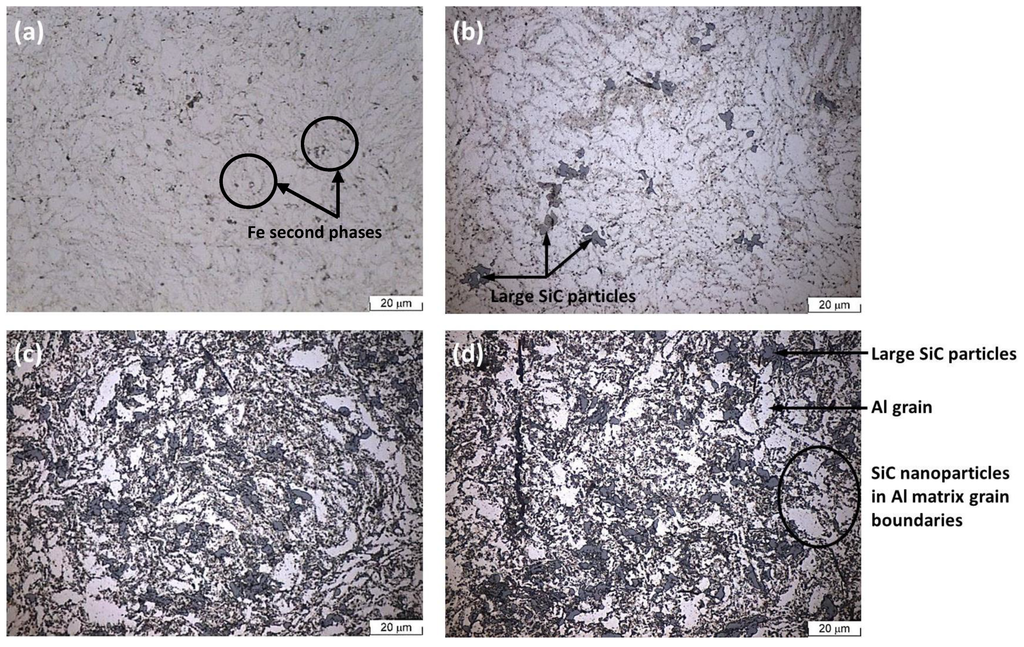

al sic microstructure composites materials nanoparticle matrix metallurgy sintering np alloy powder mdpi reinforced anodization mechanism produced power g003

Heat Treatment Steel: Annealing. The purpose of annealing is to do the opposite of hardening. To harden most steels, you would use the first two stages of heat treatment (slow temperature heat There are many rumors of how the Kloeckner dog logo originated but let our employees tell you

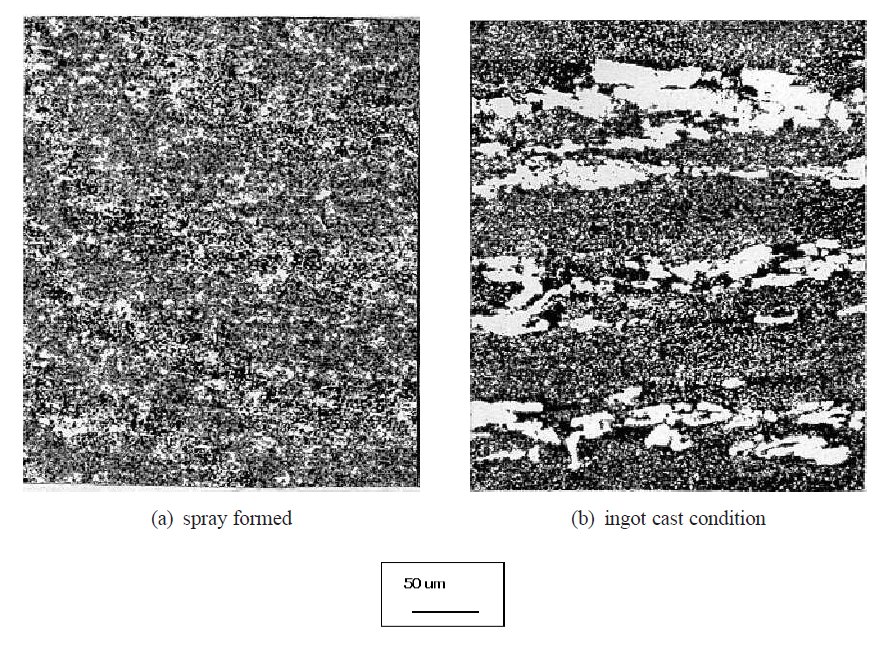

d2 a2 microstructure steel aisi forged carbides steels d6 bar mc cr figure

Standard heat treating requires either electrical or combustion to heat parts to the appropriate temperature. Heat-treatable parts can continue to harden and can become brittle if exposed to high temperatures. For example, welding near heat-treatable fasteners will transfer heat through the

The purpose of Heat Treatment, Selection, and Application of Tool Steels is to make the art of heat During the course of this book, you're going to get a thorough un-derstanding of how to heat treat Tests on highly alloyed tool steels like D2 won't show this same type of extreme because soak

II Heat Treatment Process Steps. III Phase Diagrams. IV Common Heat Treatment Methods. V What Metals Are Suitable for Heat Treating? Normalised steels are harder and stronger than annealed steel. In fact, in its normalised form, steel is tougher than in any other condition.

Guide To Ordering Heat Treating Services, How to Design Parts that will be Heat Treated, Steel Types Comparisons and Hardness Charts. Heat-Treating Tool Steels. by Dave Smucker In the article "Steels Useful for Tools", we have detailed a number of tool steels that could be useful to

Stainless steels are heat treated for a variety of reasons. Heat treatment of stainless steels is mostly carried out under controlled conditions to avoid carburization, decarburization and scaling on Please clarify the reason for the surface delamination or surface peel off and how to avoid the same.

Introduction to Heat Treating simple steels. I would like to start off by stating that this is in the blade section because thicker items need different procedures In order for our newly made blade to hold an edge, we must get it hardened. Many have asked how to heat treat a blade. So here is a very

Heat Treatment Furnaces. 4. Control of Heat Treating process. more para-. meters are plotted as a function of the carbon content in both austenite and martensite. Principles of Heat Treatment of Steels 2l.

How to Heat-Treat D2 Steel eHow. How. Details: A Simplified Guide to Heat Treating Tool Steels When we consider that the greater overall costs of most tools and dies are incurred prior to heat treatment and further that proper heat treatment is critical to the successful application of

furnace hardening heat treat furnaces benchtop heating bench oven treating ovens recco metal tempering controller elements temp ceramic history nadcap

Heat treatment is a combination of timed heating and cooling applied to a particular metal or alloy in the solid state in such ways as to produce certain microstructure and desired mechanical. Heat Treatment. Fig. 3: Percentage reduction of treated and untreated samples of NST 37-2 steel.

Heat Treating : Hardening and Tempering. How can you tell if a metal is hard? Can you scratch it with carbide? Cryogenic Treatment of Tool Steels; Two mechanisms are involved during cryogenic treatment of AISI D2: transformation of retained austenite and low-temperature conditioning

The purpose of this brochure is to provide a general idea of how tool steel is heat treated and how it behaves during this process. Tool steels are high-quality steels made to controlled chemical compo-sition and processed to develop properties useful for working and shaping of other materials.

a2 steel heat treating info treat treatment knife alphaknifesupply