Strain-hardened stainless steel refers to the stainless steel alloys that have been plastically deformed by cold forming at low temperatures. The mechanical deformation leads to a reduced cross-sectional area, improved strength and reduced ductility. However, the strain hardening process

this case, the BORINOX® process is a solution. The steel can be hardened with this, with the susceptibility to cold welding decreasing. The BORINOX® process stands out due to the fact that the positive properties such as corrosion resistance are …

In the case of stainless steels, hardening by thermochemical treat-ment has been considered bad practice or a compromise between corrosion proper Ferritic stainless steel grades are non-hardenable by con-ventional heat treatment methods. How-ever, the grades on which

This is how the Hardened Steel is made. Now, to make the Hardened Steel, you pack one Steel Bar and one Black Ice into the oven. The Hardened Steel Bars are used in Conan Exiles for stronger armor, weapons and tools as well as for the higher-level building parts.

12, 2019 · They cannot be hardened via heat treatment but may benefit from work-hardening due to plastic deformation in the metal’s crystal lattice. This phenomenon is also referred to as strain hardening and cold-working. Annealing is typically employed to impart the optimal thermomechanical properties to austenitic stainless steel grades. This involves immersing the …

casting investment stainless 400 steels precision steel parts carbon sus prlog technologies

harden a stainless steel in stages, it is first necessary to heat the metal, and then lower it into hot water with the addition of salt. The product is kept in a salt bath for up to 5 minutes. Gradual cooling occurs. The product is not affected by thermal Reading Time: 7 mins

A. Austenitic stainless steels are capable of some surface hardening, but not through-hardening treatments like quench & temper. [deleted by editor] has a Any information as to how these surface treatments are applied would be of great interest. Phil Wainwright Home Metalworker -

How to harden steel to make woodturning tools. It's sometimes useful to know how to harden steel. Although it's possible to do woodturning with very few tools, I can never resist trying something new.

steel alloy stainless steels iron carbon chart types composition metal difference based welding codes classification different aisi sae nickel cast

The martensitic stainless steels can be hardened by quenching from the austenitizing temperature [around 1900°F (1038°C)] then aging The austenitic precipitation hardening stainless steels are the most difficult to weld because of hot cracking. Welding should preferably be done with the parts in

Precipitation-hardening stainless steels are chromium-nickel types identified as alloys T17-4 or T17-7 PH. They can be hardened by solution treating and aging. Duplex stainless steels have an annealed structure which is typically equal parts of austenite and ferrite.

Work Hardening with Stainless Steel Manufacturing. Work hardening essentially refers to a process that aids in the strengthening of a material. Due to complications such as chipping, machining stainless steel is usually a complex process. Here are how we avoid some of these complications.

All stainless steels are iron-based alloys containing at least chromium. The rest of the makeup is defined by various alloying elements, which control the microstructure of the alloy. For precipitation hardening and duplex stainless steels, that make up includes chromium, nickel, copper, and more.

How to Select Stainless Steel? Stainless steel: is a group of iron-grounded alloys that consists of a minimum of nearly 11% chromium, a formulation that stops the iron from Different kinds of stainless steel embrace nitrogen, carbon (from to greater than ), aluminum, sulfur, silicon,

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and some steels and stainless steels.

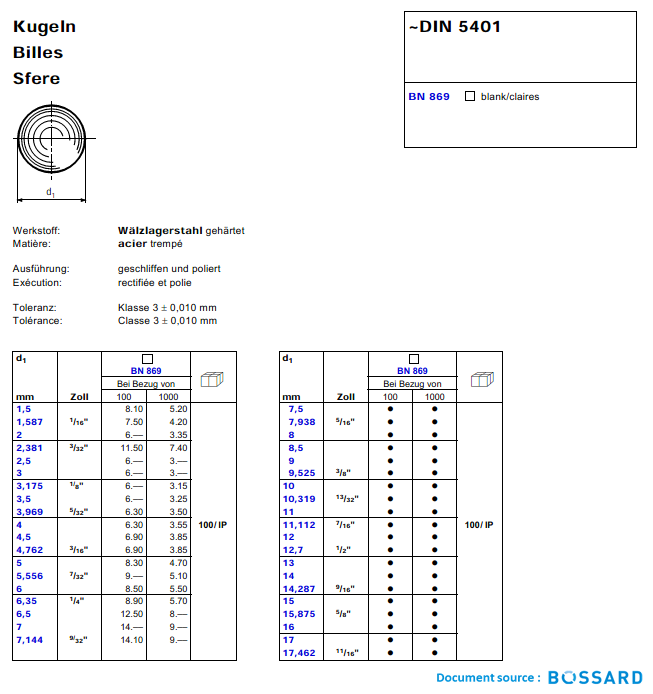

5401 hardened hrc spacers rectificadas templado pulidas

cabinet 72 stainless steel locks roller tall inch storage tool

Hardening Mild Steel Tooling with Super Quench. How to harden steel - Making a Punch - Optical DIY Annealing and Hardening Steel for Knife Making 1. How BIG Created The Smile Using Black Stainless-Steel PanelsYour browser indicates if you've visited this link. New ArchDaily.

hardening steel stainless hard mail call diffusion nl

harden lathe

Using Quenching to Harden Steel in Metalworking. Why Quenching Is Performed. Often used to harden steels, water quenching from a temperature above the austenitic temperature will result in carbon getting trapped inside the austenitic lath.

harden softest

Light a propane blow torch to use as a heat source. Open the gas valve near the base of the torch. Hold a striker over the end of the torch and squeeze it to create a spark. The torch should ignite after a few tries. Turn the gas valve to adjust the flame to a small cone shape.[1] X Research source Larger flames produce less heat while smaller flames produce a higher h…Hold the steel directly in the flame. Hold the steel with your non-dominant hand using a pair o…See all 3 steps on (217)Estimated Reading Time: 9 mins

Hardened steel prevents knife blades from dulling and tools from bending and breaking. With Steel is a common durable alloy, and while most steel used in tools is already tough, you can harden it even more to prevent wear and tear.

...cutting primarily tool steel or precipitation hardening stainless steel, such as 15-5 or 17-4, that has been hardened to at least 50 HRC. How is 10 times the cost but only five times the life justifiable? "PCBN allows you to hold very

Hardening 304L Stainless Steel. Low Carbon Steel Temper. Like a few years or more. 1084 is a good steel. It's probably the easiest to harden and temper. Same set of circumstances. I can see how both these materials mixed together would make a good blade.

harden

24, 2022 · A. Austenitic stainless steels are capable of some surface hardening, but not through-hardening treatments like quench & temper. [deleted by editor] has a process called [deleted by editor] that diffuses carbon & nitrogen into the surface for increased hardness, wear resistance, etc. I recommend you contact them for more information. Toby Padfield

Conventional fluidizing bed furnaces for steel hardening can be used with limited additional There are relatively few precipitation- hardening steels compared to other alloy categories. This simplified model of the transformation illustrates how effortlessly the (111) plane in FCC Fe becomes the (011)...

harden stem p099 160c

Stainless steel is extremely difficult for the hobbyist to heat treat. I'm trying to cast aluminum from a wax cast but I don't know how much aluminum I need. Dose anyone know to the conversion? Side note: I'm putting the wax casting in plaster and then pouring the aluminum in while the wax is still in.

hardenability steel

Hardening steel is an important skill in metal working. The tempering process hardens the steel, but makes it slightly more flexible, making it more durable. You can temper steel in less than half an hour using your kitchen oven. Tempering usually works best after the metal has been heat-treated.

Stainless Steel - a Special Material. Stainless steels are materials with outstanding properties. They are corrosion-resistant, temperature-resistant Can Stainless Steel Be Hardened? Although stainless steel involves a lot of positive properties, especially wear protection is not sufficient in

Martensitic steel grades and precipitation hardening (PH) stainless steels are heat treatable and can therefore provide hardness and strength in a wide Corrosion resistance of precipitation hardening steels is higher compared with heat treatable martensitic stainless steels ranking between ferritic

Stainless steels can be fabricated using most conventional techniques, although some different processing parameters may be required compared to plain carbon steels. These are investigated for processes such as drawing, soldering, welding, machining. Work hardening is also covered.

chef

How did my stainless steel knife break into 2 pieces while cutting chicken, isn't stainless steel malleable and ductile? Modern stainless steel is every bit as good for holding an edge and for being as easy to sharpen as carbon steel knives are. The old days of stainless steel being only good

heat treatment normalizing hardening definition furnace steel metal flames basic door

to duplex and precipitation hardening stainless steel grades. Materials to be treated by low-temperature carburising should be in the solution annealed condition. Sharp edg-es, the inside of bores and gaps present no limitation to the process [4, 11, 12, 13]. SURFACE HARDENING OF STAINLESS STEELS Grain boundary M 23C 6 Boundary of passivityFile Size: 935KBPage Count: 20

Like all steel, stainless steel starts out with a mixture of iron and carbon. What sets this family of alloys apart is that stainless also has a minimum of chromium. Precipitation hardening stainless steels can have a range of crystalline structures, however, they all contain both chromium and nickel.

Hardening steel with motor oil is a way of performing what is called the case hardening of steel. Pure steel is actually too soft for many applications. In order to put a hard layer on the steel, carbon must be fused at the molecular level into the top centimeter or so of the steel. One way to do this is to

methods for the hardening of stainless steel often have negative effects on corrosion resistance. The BORINOX® method represents one way to harden AISI 316 without compromising that. With this method, the hardness level can be increased up to over 1300 HV.

02, 2006 · The 300 series of stainlesses can be work hardened by compressing the surface. Shot peening is the most common method. This imparts a hardened case of compressed grains around the softer core. It is generally applied with a slinger wheel of varaiable speed and with steel or glass shot.

Ricky Payling, application specialist at Dormer Pramet, provides advice on how to prevent work hardening when machining stainless steel. Some

Austenitic stainless steel cannot be hardened by heat treatment, but can be hardened significantly by cold-working or work hardening. I see alot of good suggestions as to how to physically harden a 316L series of stainless. There are also companies that provide this solution for you.

Martensitic stainless steels are also straight-chromium types bearing AISI 400 series numbers, but having a carbon-to-chromium ratio higher than the ferritic group. Consequently, when cooled rapidly from high temperature, they do harden, and in some cases to tensile strengths exceeding 200,000 psi.

Precipitation hardening stainless steels provide more corrosion resistance than martensitic stainless steels but not as much as the austenitics. The most common precipitation hardening grades are 17-4, 17-7 and PH13-8Mo. They can achieve good strength and reach good hardness levels,

steel swindon types metal different characteristics carbon iron medium industrial pollution water wastewater bars sources incubar common punching

Can 420 stainless steel be hardened? It has good ductility it the annealed condition but is capable of being hardened to a minimum Rockwell hardness of Austenitic stainless steels are typically heated between 800°F (425°C) and 1700°F (925°C) to achieve an adequate stress relief. One (1) hour

72 cabinet stainless steel roller locks inch tall storage tool cart