Alloy 17-4PH (UNS S17400), Type 630, is a chromium-nickel-copper precipitation-hardening martensitic stainless steel with an addition of niobium. 17-4PH combines high strength and hardness with good corrosion resistance. 17-4 is a common named used by two or more producers, not

In this video, Gary " The Brand Ambassador " demonstrates how to fold and reduce using 17 Degree universal double sided folding reduction dies Legacy coin ring reduction and folding dies are machined from heat treated and hardened 17-4 stainless steel Stainless steel dies means no more

Martensitic stainless steels offer significantly higher strengths but have to low ductility. For this reason for application where high levels of strength and [2] Reinshagen, Witsberger:, Properties of Precipitation Hardening Stainless Steel Processed by Conventional Powder Metallurgy

17-4 PH stainless steel is a martensitic stainless steel containing approximately 3 wt pct Cu and is strengthened by precipitation of copper in the martensite matrix. Studies of precipitation-hardening stainless steels indicate that material at the peak hardness or slightly over-aged may have

Hardening 304L Stainless Steel. Low Carbon Steel Temper. Most of the tempering I've done is with 1084 tool steel. As I'm a beginner this is where most people suggest you start because of the ease of tempering. Supporting Member. 17. 845 posts. Gender: Male.

17-4PH stainless steel stockholders and suppliers, delivering to the whole of the UK. As a martensitic precipitation hardening stainless it is characterised by high tensile strength and high yield strength obtained by solution annealing, followed by a single or double low temperature

The normal procedure to case harden 17-4 stainless is to nitride it. You first have to heat treat to the H-1075 or H-1150 condition. SS (17-4) does not respond to carbon like steel, the case hardening is sorta not good. Nitriding is the way to go as stated above.

Hardened steel prevents knife blades from dulling and tools from bending and breaking. With a simple heating and quenching process, you can make your steel last for much longer! "I was looking at making a set of plate armor and I wanted to see how to harden the breastplate.

to duplex and precipitation hardening stainless steel grades. Materials to be treated by low-temperature carburising should be in the solution annealed condition. Sharp edg-es, the inside of bores and gaps present no limitation to the process [4, 11, 12, 13]. SURFACE HARDENING OF STAINLESS STEELS Grain boundary M 23C 6 Boundary of passivityFile Size: 935KBPage Count: 20

wire cutter rope harden steel t8 alloy professional cc cutting

So I am wondering if I need to do something special to harden it, if if I just did not get it hot enough. (I do not have much to heat a blade right now just Stainless steel is extremely difficult for the hobbyist to heat treat. Most knifemakers who work with stainless send their blades to professional

This product is used in vibratory finishing of 17-4PH Stainless Steel turbine blades for ground based electrical Electropolishing is a common finishing method for all of the precipitation hardened alloys, offering a bright We can furnish complete information on electropolishing any type of stainless steel.

protractor harden bevel stainless steel

30, 2016 · To further strengthen the stainless steel, they are subjected to heat treatments which result in the precipitation hardening stainless steel material. One of the most used types of PH stainless steel is 17-4 PH stainless steel. There are many things that you probably did not know about the alloy? Take heart, though.

30, 2018 · Heat to 1,900F and soak for 1 hour. Air quench to below 90F and THEN heat to 900F. H900 is difficult to machine, so you might want to do most of the machining before heat treat. JR. The correct process for heat treating condition a 17-4 to h900 is to heat to 900°f soak for 1 hour then cool.

Steel AL 17-4™ Alloy SUMMARY OF HEAT TREATING AL 17-4 ™ ALLOY Minimum Properties Specified in Aerospace Material Specification (AMS) 5604 Heat Treat to Produce Martensitic Structure Precipitation Heat Treatment to Produce Desired Strength Solution Heat Treatment at 1950 °F (1066 °C) Precipitation Hardening Heat Treatment 900 °F (482 °C) 60 …File Size: 39KBPage Count: 4

hardening steel stainless hard mail call diffusion nl

induction brazing heating copper steel welding frequency heater inductionheater dw hard pipe diy tube stainless machine hardening metal tubing rf

harden sprayer botter

closed steel

12, 2019 · They cannot be hardened via heat treatment but may benefit from work-hardening due to plastic deformation in the metal’s crystal lattice. This phenomenon is also referred to as strain hardening and cold-working. Annealing is typically employed to impart the optimal thermomechanical properties to austenitic stainless steel grades. This involves immersing the …

harden softest

All stainless steels are iron-based alloys containing at least chromium. The rest of the makeup is defined by various alloying elements, which control the Precipitation Hardening: 17-4/Type 630. Where to use it: Helicopter deck platforms, the paper industry, turbine blades, and nuclear waste casks.

Ferritic stainless steel grades are non-hardenable by con-ventional heat treatment methods. How-ever, the grades on which surface hard-ening can • Precipitation-hardening stainless steels. Steel grades such as , (17-4 PH), , (17-7 PH), (15-5 PH),

17-4 PH is a martensitic precipitation - hardened stainless steel. It's known for its corrosion resistance and high levels of strength and hardness, especially when heat treated. 17-4 can be heat treated to a variety of hardness and toughness levels, allowing users to customize post-sintering properties of

Applications Potential 17-4 PH Stainless Steel is the most widely used of all the precipitation-hardening stainless steels. Its valuable combination of properties gives designers opportunities to add reliability to their products while simplifying fabrication and often reducing costs.

harden softest

Type 17-4 PH stainless steel is the most widely used of all of the precipitation-hardening stainless steels. Its valuable combination of properties gives designers opportunities to add reliability to their products while Stainless 17-4 PH. Physical Properties Linear Coefficient of Thermal Expansion.

harden slightly worn vol condition

To harden 4130 heat it to 1650F to 1700F depending on how long it take you to get it into the quench tank 202 Stainless Steel Hardened to HRC40 201/202 Stainless Steel is a somewhat lower cost version of 17-4ph Stainless Steel The corrosion resistance is close to that of 304 stainless steel.

Introduction RA17-4 is an age-hardening martensitic alloy combining high strength with the corrosion resistance of stainless steel. Hardening is achieved by a short-time, simple low-temperature treatment. Unlike conventional martensitic stainless

china harden functional wholesale multi utility knife 18mm 3pcs cutting safety plastic tools

02, 2006 · To anneal it, get it hot and quench it quick. To harden, get it hot and let it cool slowly. Or you could always use my tried and true method of "spot" hardening stainless - drill a hole and run the drill fast and feed too aggressively. …

Hardening steel is an important skill in metal working. The tempering process hardens the steel, but makes it slightly more flexible, making it more Johnson's poetry has appeared in such publications as "Sphere" and "17 1/2 Magazine." eHow may earn compensation through affiliate links in this story.

harden

Stainless steels are known as high-alloy steels. They contain about 4-30% of chromium. They are further divided into martensitic, austenitic, and ferritic steels. Another group of stainless steels are known as precipitation-hardened steels.

ensure the best condition for the hardening operations, the forgings must be re-heat treated at 1875-1925°F. Cool forgings to below 90°F to ensure grain refinement. Processing – Cold Forming: Alloy 17-4 is limited to mild operations since in the annealed (solution treated) condition the material is hard.

From Specialty Steel Supply: "Stainless steel 17-4 H1150 is stainless steel grade 17-4, also known as 630 alloy, that has been heat treated at a The H900 treatment will only harden 17-4 to ~Rc44-45, so it usually isn't used for cutting instruments--440C or a newer alloy is the stainless of choice there.

Martensitic stainless steels offer significantly higher strengths but have to low ductility. For this reason for application where high levels of strength and a One of the most popular alloy of this kind of stainless steel is 17-4 PH. The aim of the present paper was to examined the influence the

PropertiesCorrosion ResistanceMechanical PropertiesAlloy 17-4PH (UNS S17400), Type 630, is a chromium-nickel-copper precipitation-hardening martensitic stainless steel with an addition of niobium. 17-4PH combines high strength and hardness with good corrosion resistance. The alloy is furnished in the solution annealed condition (Condition A). It should not be used at temperatures above 572°F (300°C) or for cryogenic servi…See more on

Precipitation hardening stainless steel 17-4PH coatings were successfully deposited on the AISI 304 substrate via friction surfacing (FS) for enhancing the surface hardness. Sintering conducted at four different temperatures, at 1320 °C, 1340 °C, 1360 °C, and 1380 °C. The results showed that there

17-4 stainless steel is a martensitic, precipitation-hardening stainless steel. At the solution treating temperature, 1900°F (1040°C), the metal is austenitic but undergoes transformation to a low-carbon martensitic structure on cooling to room temperature. This transformation is not complete until

Stainless steels, a chromium-rich subset of steels, have numerous hardening mechanisms that are all found within the greater family of steels. You'll only work harden a 304 stainless steel, but can age (precipitation harden) 17-4PH, and can quench-and-temper 440C.

hardenability steel

Stainless Steel AL 17-4™ Precipitation. Hardening Alloy. Allegheny Ludlum's AL 17-4™ Precipitation Hardening Alloy (S17400), Type 630, is a chromium-nickel-copper precipitation hardening stainless steel used for applica-tions requiring high strength and a moderate level

There are relatively few precipitation- hardening steels compared to other alloy categories. A group of iron-chrome-nickel alloys with relatively small nickel proportions. Table shows some examples of failure analysis of PH stainless steels collected in the literature in the last years.

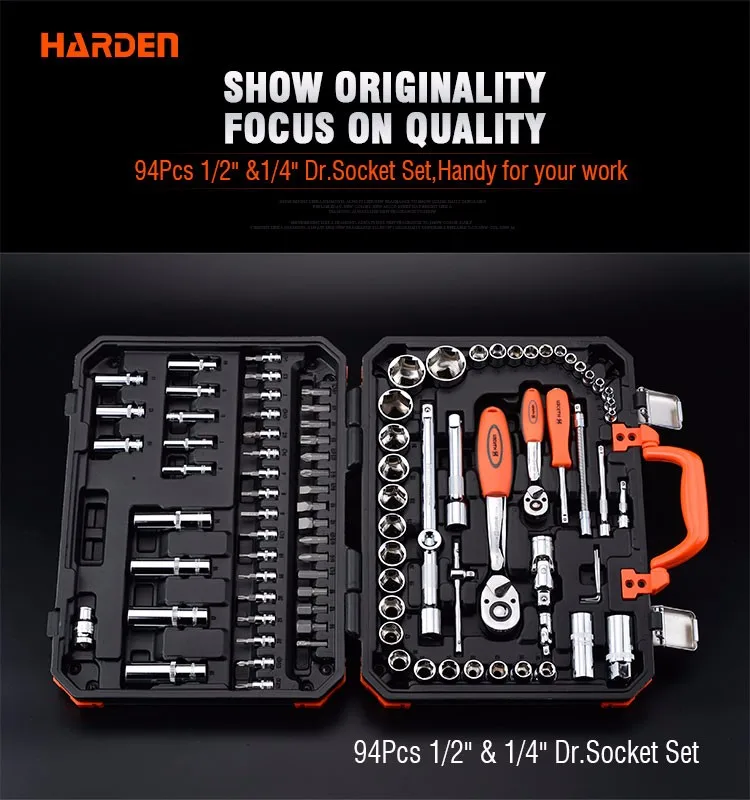

harden tools vanadium chrome 94pcs socket dr professional tool hand h8

Stainless Steel 17-4PH reacts best to hot forming at 1742 to 2192 °F (950 to 1200 °C), with annealing at 76 °F (25 °C) and aging. The alloy can also be cold-formed in limited form, primarily to plates in the annealed condition. However, stress corrosion resistance can be improved with re-aging.

Martensitic Precipitation Hardening Stainless Steels Precipitation-hardened stainless steels are widely used as structural materials for chemical and power plants because of their balanced combination of good mechanical properties and adequate corrosion resistance. 17-4 PH stainless steel is a martensitic stainless steelFile Size: 1MBPage Count: 21

SAE Type 630 stainless steel (more commonly known as 17-4 PH, or simply 17-4; also known as UNS S17400) is a grade of martensitic precipitation hardened stainless steel. It contains approximately chromium and 3-5% nickel, as well as 3-5% copper.

harden softest

Precipitation-hardening stainless steels have seen limited use in powder metallurgy (PM) despite their high strength. The strengthening of these alloys is Abstract Microstructural development and aging reactions in a commercial 17-4 PH (precipitation hardening) stainless steel have been investigated.

PH. Figure 9 shows how the concentration of carbon in the steel affects the amount of retained austenite. The atmosphere requirements for avoiding oxidation of commercial stainless steels, with oxidation of iron and pure chromium as references, are illustrated in Figure 30.

harden lathe

Stainless Steel (coming from the chemical makeup 17% chromium and 4% copper or UNS 17400) is a martensitic stainless grade that can be precipitation hardened through aging/heat treatment. 17-4 stainless steel, otherwise known as SAE Type 630 is frequently used with operations demanding high tensile strength and a middling level of corrosion resistance. 17-4 P…See more on