plasma corona lamp discharge treatment flame electricity ball violet parker bill tesla current comparing dielectric orange gas ozone physics nikola

acute

Flame Treating - What is does. Flame treating is a process in which heat and alcohol are introduced to the PE or PP plastic part to make the bonding of the paint or film possible on the plastic part.

Flame Treatment Systems. GR-X flame treaters are proven to provide a safe, consistent and reliable solution for effectively surface treating plastic bottles. Surface treatment systems are ideally suited to enhance the adhesion of bottle labels and printing prior to application.

Flame treating and corona treatment are not the same thing although they are often used for the same purpose, , to increase the surface energy of polymer surfaces for Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers

For over 40 years, Flame Treating Systems, Inc. has built flame hardening systems and provided customers with inhouse flame hardening services. If you have questions about using flame hardening in your heat treating solution, email me at mark@ or

Adhesion and Surface Treatment of Plastic. During the surface treatment of plastic, producers are often challenged with the task of increasing the surface's energy level making it greater than the surface tension of the coating, printing ink, and paint or adhesive so as to increase the chemical attraction.

Burning plastic is characterized by bubbling and black specs. If you burn your plastic, sand off the damaged material and try again. I feel like you are not grasping the point of this instructable, which is not about what type of polishing technique is better, but is only about how to flame polish plastic.

In this video, we demonstrate how to proper flame treat and ATV hood prior to the Water Transfer Printing process. This will help the paint bond to the substrate. This is particularly needed for Polyethelyne and other raw plastics.

They assured me that flame treating has never been a part of their procedure and they do show cars. Seems like this scenario has so many different This is exactly what I've always wondered. HDPE is the only plastic I flame treat. The other chemical prep products work fantastic on Polypropylene.

Flame treating plastic involves fire, so take all the necessary precautions when dealing with an open flame. If you have tried this technique out on one of your 3-D SF&F projects, let me know how it worked out for you!

Plastics: Clean plastics, except for polycarbonate, with isopropyl alcohol to remove contamination. Sand all plastics including polycarbonate with Flame treat ABS and PVC for additional benefit. HDPE (high-density polyethylene) and LDPE (low-density polyethylene) must be flame treated

Flame Treating Plastic | How to prep plastics for painting or hydro dippingIn today's video, we will are continuing our video series called:Just The Tip!

How To Flame Treat Plastic For Paint (1 min 58 sec). And THEN you're going to have to try to find someone who would be willing to teach you how to fly the thing, as it won't fly itself.

country boots

haryana national india indian bharat study level role child

Flame treatment is the application of a gas flame to the surface of a material to improve adhesion. Polyolefins, especially polyethylene and polypropylene bond poorly, because they consist of long non-polar molecules.

Application Flame Treament Machinery,flame machine, flame treatment,printing technology,PP PE printing, surface treatment and it is mainly used for pre-treatment of polyethylene and polypropylene plastic products. The better ink adhesion is available after the pre-treatment.

How To Flame Treat Plastic For Paint. 1:58. Spiral Hose Guards - Letkunsuojat - HAVEL Oy.

The concluding section outlines how the most significant features of flame treatment can be profitably used to improve the wettability and adhesion properties of The purpose of this work is to determine the surface wettability of polymers suitable for food contact. These plastics have been treated

trick treat 70s halloween costumes retrospace attire

How to flame treat plastic for paint. Make PAINT stick to PLASTIC! (Flame Treatment) How to paint tricky plastics like PP, LDPE, Подробнее. Flame Treating Plastic | How to prep plastics for painting or hydro dippingПодробнее. Pre-treatment of plastics before printingПодробнее.

Instructions also said to "flame treat" the plastic first. I'd not seen that in the how-to's before. It says the flame oxidizes the surface and creates a better bond. Follow carefully the directions, and when you are ready to stick it together, make sure it is correctly aligned--because once the two

Plastics that are flame treated will stay good for maybe a month if left sitting on the shelf. When someone orders 1000 cups, they flame treat them, and they are ready to print. How do I flame treat plastic at home? You can use a plumber's hand held propane tank with a torch tip.

Firstly how well the ink transfers to the plastic, and secondly if the plastic bounding to epoxy is affected. after the cooling it is good idea to flame treat the base/topsheet (PA nylon) to improve adhesion to epoxy. Hints: If you graphics is fading at the ends, you probably have uneven

Flame treatment of plastic surfaces is also a quality conscience method of plastic surface treatment options. Consistent exposure to a controlled flame Systematic Automation offers proven plastic surface treatment solutions with flame treating systems constructed of quality materials, made in

Flame Treating Plastic | How to prep plastics for painting or hydro dipping In today's video, we will are continuing our video series ... Flame Cell - Robotic flame treatment of plastic parts as a preparation for application of adhesive or painting.

xgk ii msr 1981 1994 burner enclosure unit classiccampstoves

I know it's necessary on TPO plastics, want to know the science behind how it works. In addition, why does epoxy provide a better bond over a urethane I was hoping JimC would have backed me up on the flame treatment. But, the company Polyvance (they produce plastic repair materials)

chamber vacuum plastic industry fabrication

international california ed names indian water study country number age gurugram under govt super national level punjab making would

To flame-treat the plastic, hold a propane torch about 15cm above the surface so that the flame just touches the plastic. Move it across the surface very quickly, at a rate of about 30-40cm per second. Keep the torch moving and make sure you work your way up and down the plastic carefully

Flame treating is one method whereby the surface of polyolefins may be made polar through oxidation. The problem is how much air is required to complete this combustion for a given volume of any hydrocarbon gas. The following equation can be used to determine this value

The PyrosilPen flame treatment technology was investigated by surface-treating silicate, aluminum oxide, and zirconium oxide ceramics. Flame treatment is defined as a surface preparation technique in which the plastic is briefly exposed to a flame. Flame treatment oxidizes the surface through

Flame treatment is the most widely used and cost effective pre-treatment for polyethylene (HDPE, LDPE, UHMW) and polyolefin based plastics prior to This treatment brings about a change to the polymer surface that increases its surface energy allowing fluids to effectively wet-out the surface

In flame treatment, an oxidizing flame is deployed so as to impinge on the surface for a very short time (thus avoiding melting the plastic). A technique similar to flame polishing can be used to treat certain plastic surfaces before coating or adhesives bonding.

Activate plastic surfaces for adhesion by cleaning, etching and functionalizing with plasma, flame & corona treating. For most web and film applications corona treaters are widely used. For higher and longer lasting treatment levels atmospheric plasma with variable chemistry is employed.

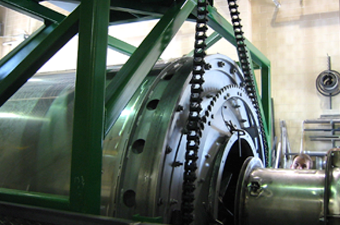

sprocket sprockets gears gear industries serve flame